Buffer oil supplementing system and method of electro-hydraulic double-control motor-driven rotary system

A motor-driven, rotary system technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of inability to realize hydraulically controlled automatic oil replenishment, low degree of automation, insufficient oil storage and replenishment, etc. The effect of saving construction cost, improving service life and simple system composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

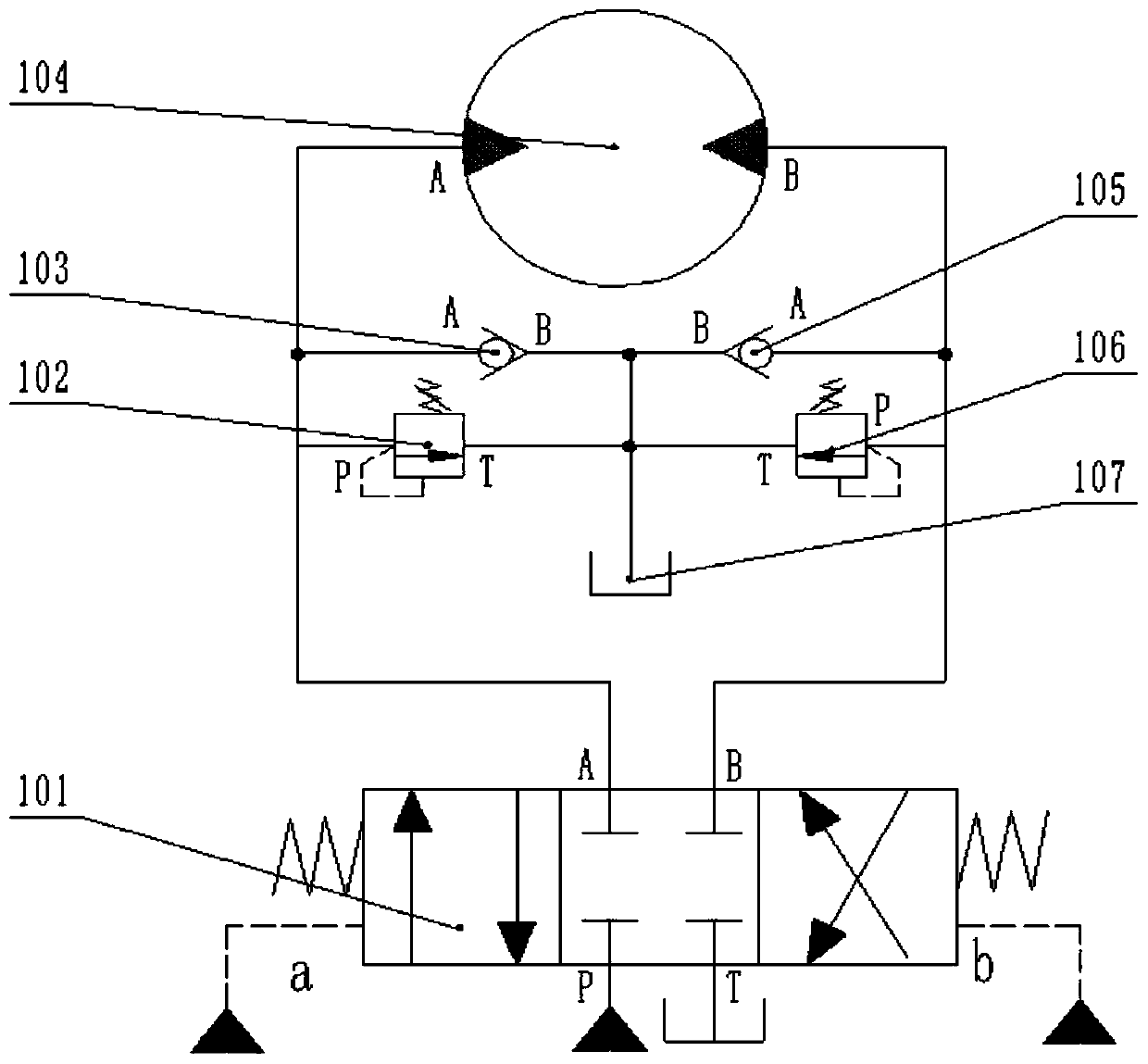

[0031] see figure 1 , figure 1 It is the schematic diagram of the existing buffer oil replenishment hydraulic system. There are buffer overflow valves 102 and 106 at the motor A and B ports. Two oil replenishment single-way valves 103 and 105 are respectively connected to the motor A, B port and the oil tank, and work as a multi-way valve. In the left position, the motor rotates forward as an example, and the oil enters the A port and the B port returns the oil. The motor rotates. During this process, when the reversing valve suddenly switches to the right, the motor continues to rotate forward due to inertia At this time, due to the reversing of the multi-way valve, the motor is changed to B to feed oil. At this time, a high-pressure shock will be generated at the B port of the motor. When the shock pressure is greater than the set pressure of the buffer overflow valve 106, the buffer overflow valve will open and the load will be unloaded. In order to achieve the purpose of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com