Ventilation, dust removal and purification system

A purification system and cycle purification technology, which is applied in the field of ventilation, can solve the problems of high overall energy consumption, high system resistance, and high energy consumption of the refrigeration system, and achieve good ventilation and dust removal effects, reduced total energy consumption, and low system energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

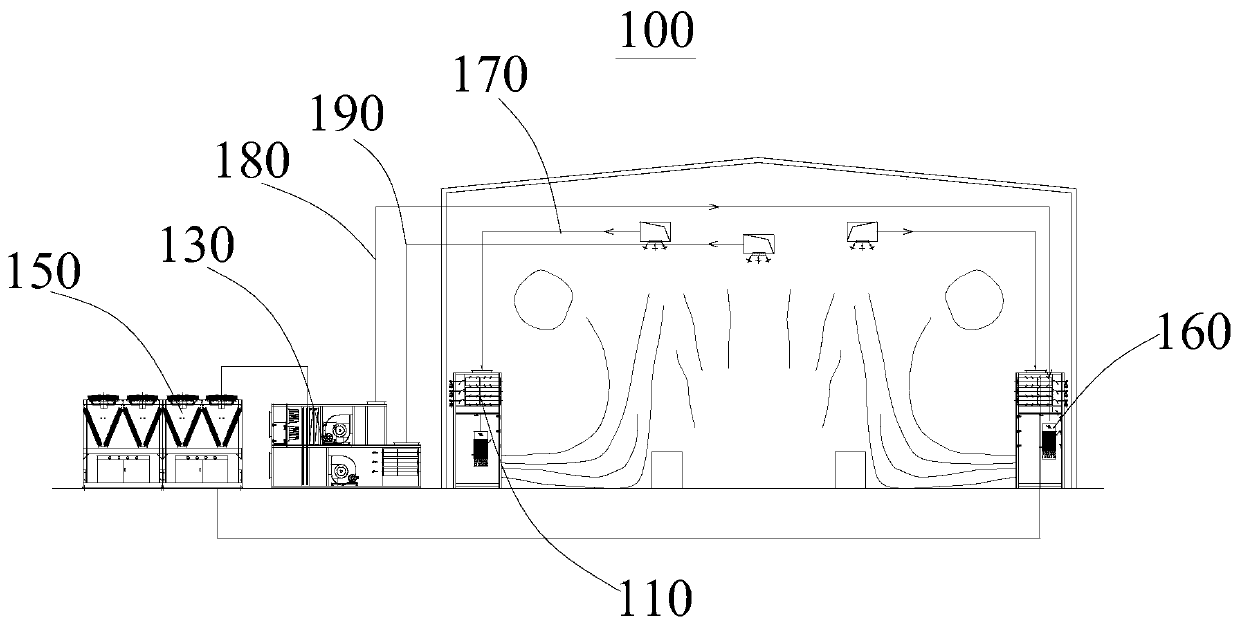

[0037] see in conjunction Figure 1 to Figure 3 , the present embodiment provides a ventilation, dust removal and purification system 100, which is mainly installed in the factory building 200, and plays the functions of ventilation, dust removal and purification of the air inside the factory building 200, and simultaneously controls the temperature and humidity inside the factory building 200 separately, Play the role of independent control of temperature and humidity.

[0038] The ventilation, dust removal and purification system 100 provided in this embodiment includes at least one circulation purification unit 110, at least one fresh air unit 130 and heat exchange unit 150, and the heat exchange unit 150 is respectively connected to the circulation purification unit 110 and the fresh air unit 130 for Exchange heat with the purification unit and the fresh air unit 130 respectively. The circulation purification unit 110 is arranged in the indoor space and is provided with a ...

no. 2 example

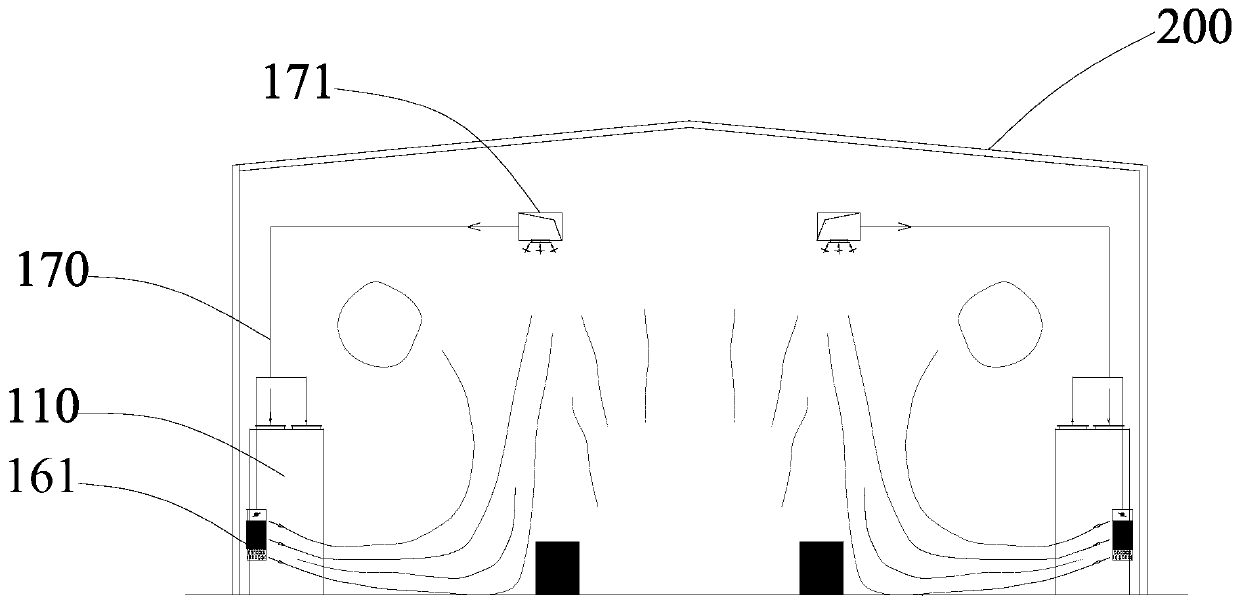

[0070] see in conjunction Figure 6 and Figure 7 , this embodiment provides a ventilation, dust removal and purification system 100, its basic structure and principle and the technical effects produced are the same as those of the first embodiment. corresponding content in the example. Compared with the first embodiment, the difference of this embodiment lies in the circulating purification unit 110 .

[0071] In this embodiment, the circulation purification unit 110 includes a circulation housing 111, a return air valve 113, a circulation purification assembly 115 and a static pressure air supply diffuser 119, the circulation housing 111 is arranged in the indoor space, and the return air valve 113 is arranged in the circulation One end of the housing 111 is connected to the air return pipe 170. The static pressure air diffuser 119 is arranged at the other end of the circulation housing 111 and has an air outlet. The circulation purification assembly 115 is accommodated in...

no. 3 example

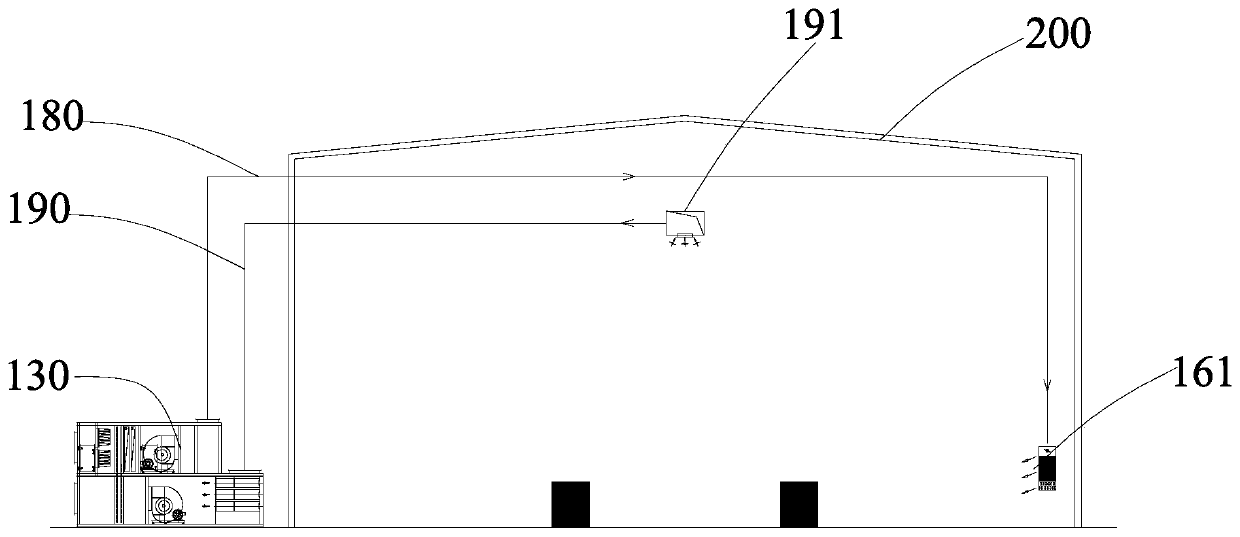

[0074] see Figure 8 , this embodiment provides a ventilation, dust removal and purification system 100, its basic structure and principle and the technical effects produced are the same as those of the second embodiment. corresponding content in the example. Compared with the second embodiment, the difference of this embodiment lies in the circulating purification unit 110 .

[0075] In this embodiment, the circulation purification unit 110 includes a circulation housing 111, a return air valve 113, a circulation purification assembly 115 and a static pressure air supply diffuser 119, the circulation housing 111 is arranged in the indoor space, and the return air valve 113 is arranged in the circulation One end of the housing 111 is connected to the air return pipe 170. The static pressure air diffuser 119 is arranged at the other end of the circulation housing 111 and has an air outlet. The circulation purification assembly 115 is accommodated in the circulation housing 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com