Polymer microcavity filling micro-structured optical fiber based quasi-distributed temperature sensing system and its signal demodulation method

A microstructured optical fiber and sensing system technology, applied in the field of sensing, can solve the problems of air hole design increasing the difficulty of device preparation, complex directional coupling matching conditions, limiting microstructured optical fibers, etc. The effect of simple processing and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

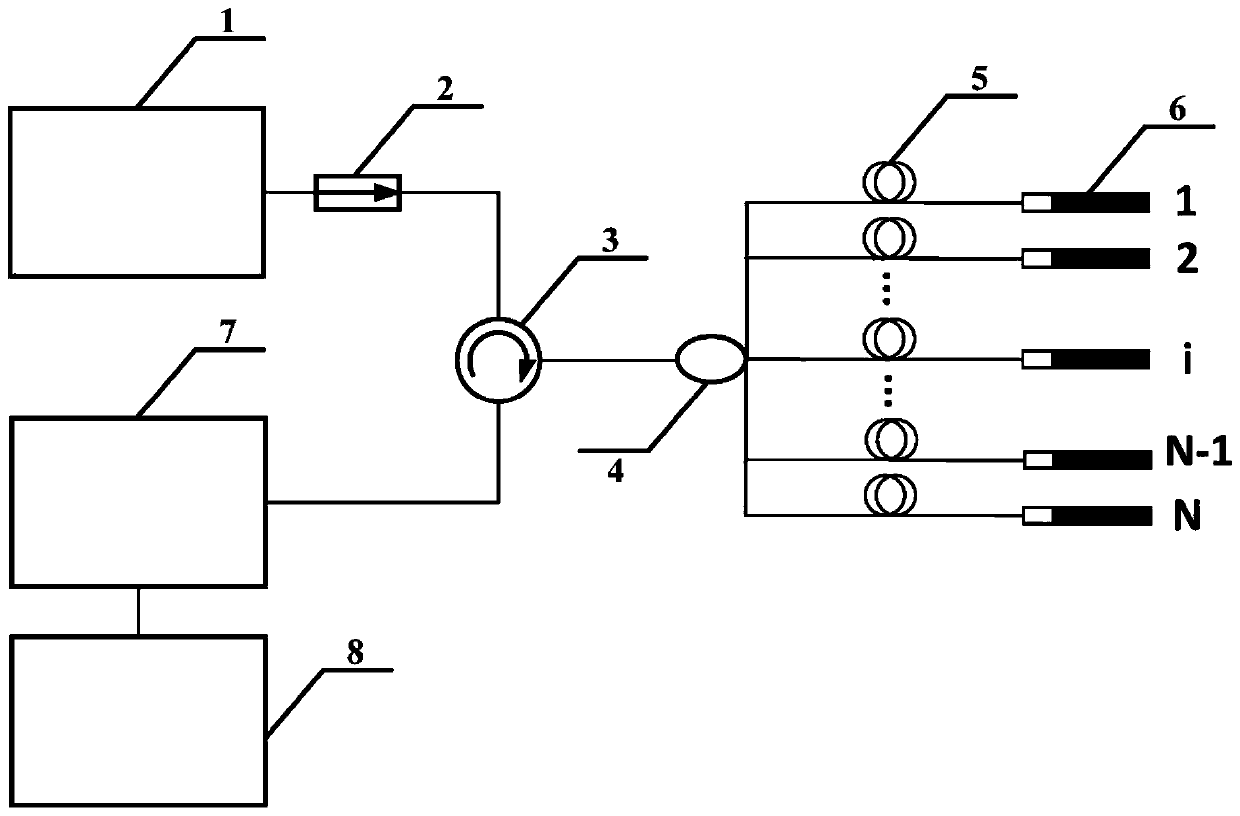

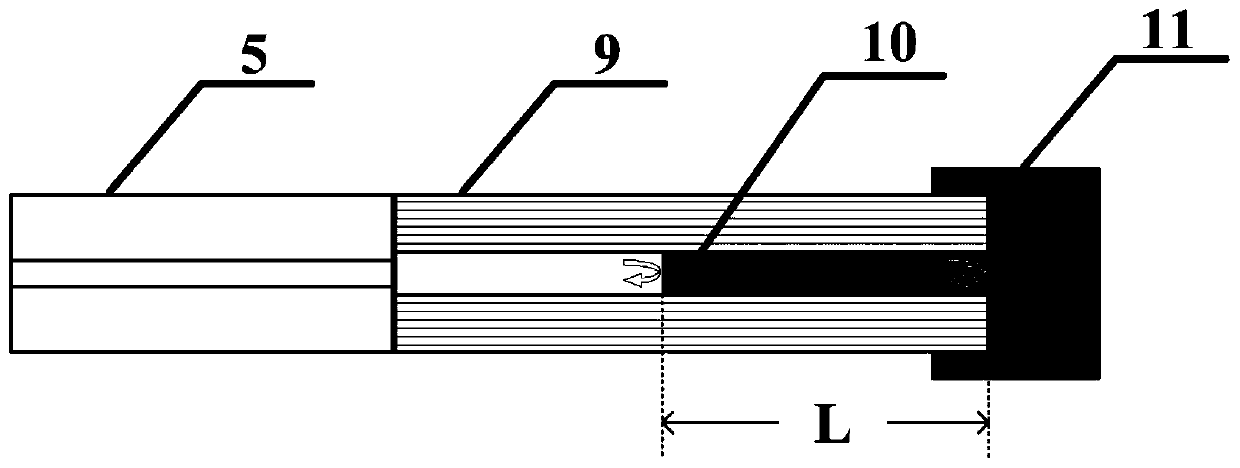

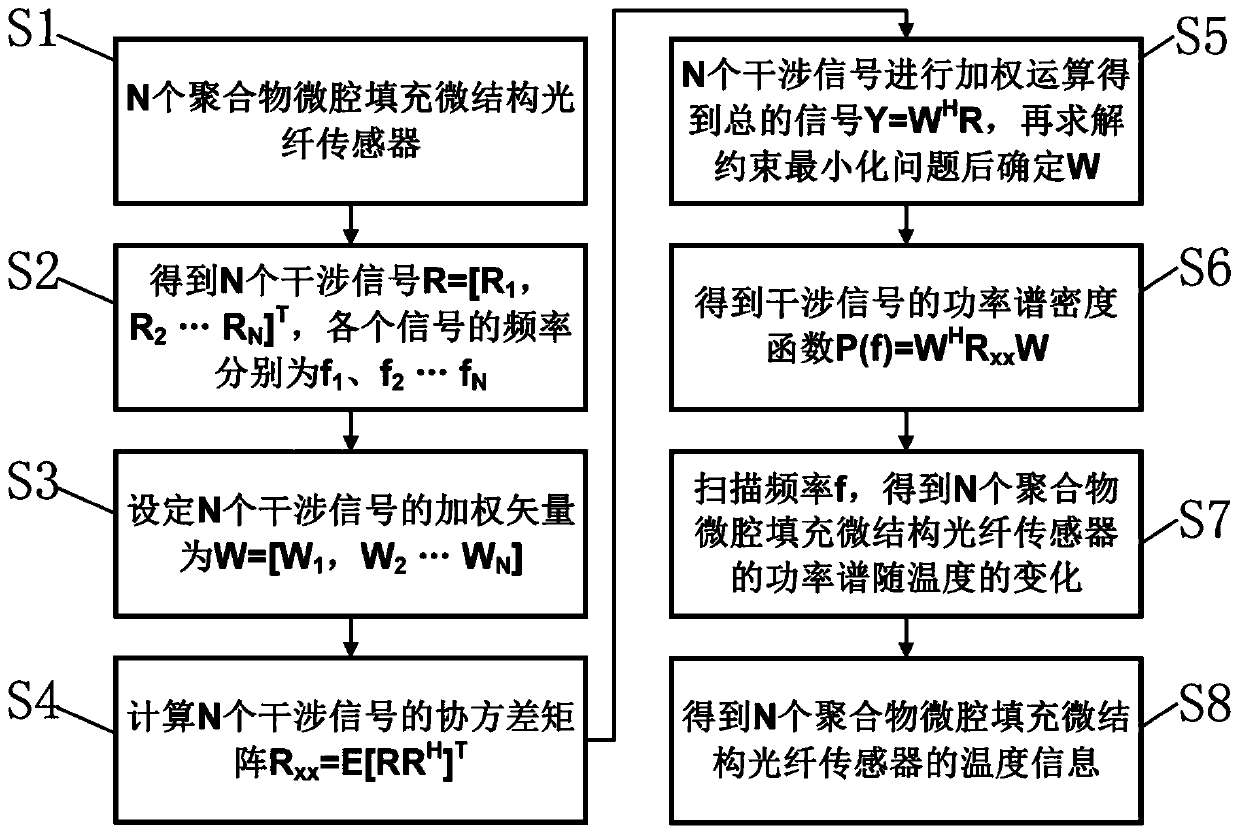

[0029] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention discloses a quasi-distributed temperature sensing system based on a polymer microcavity filled microstructured optical fiber, such as figure 1 As shown, it includes: a broadband light source 1, an optical isolator 2, an optical circulator 3, a fiber coupler 4, a single-mode fiber 5, a polymer microcavity filled microstructure fiber sensor 6, a spectrum analyzer 7 and a computer 8. In this embodiment, the fiber coupler 4 has 1 input port and N output ports, and is defined as a 1×N fiber coupler, wherein the broadband light source 1 is connected to the optical circulator 3 through the optical isolator 2, and the optical circulator 3 The output ports of the 1×N fiber coupler 4 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com