Method and device for measuring volatile quantity of ammonia gas in livestock and poultry manure

A technology of volatilization and ammonia, applied in the biological field, can solve the problems of difficulty in measuring ammonia in cattle barn, time-consuming and laborious, and high cost, and achieve the effects of accurate ammonia volatilization, low cost, and simple and convenient environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

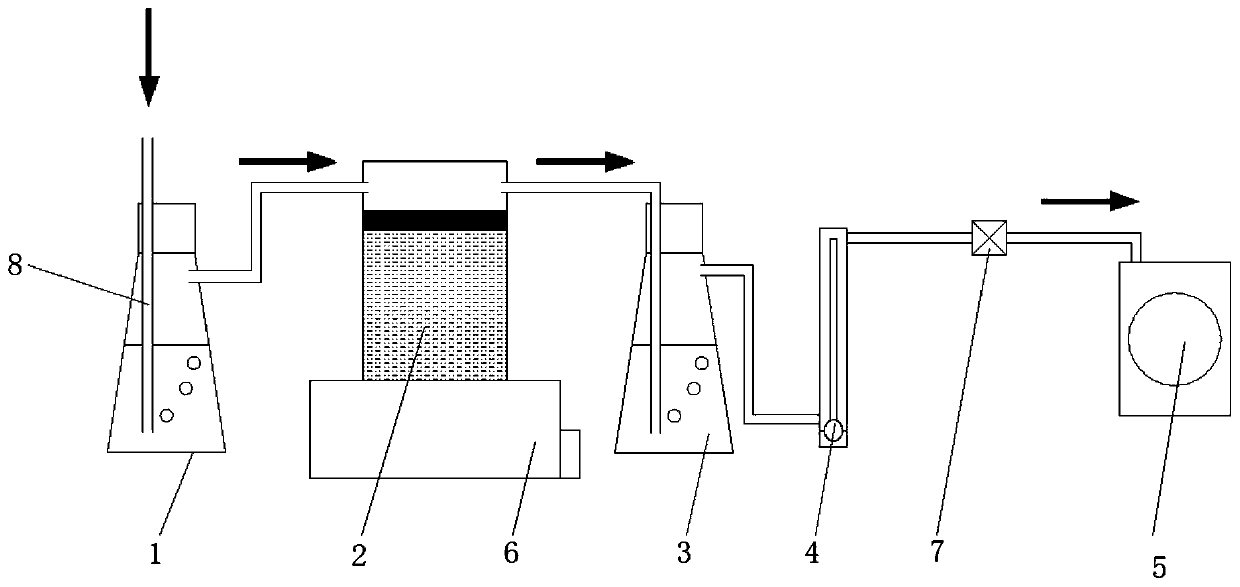

Method used

Image

Examples

Embodiment 1

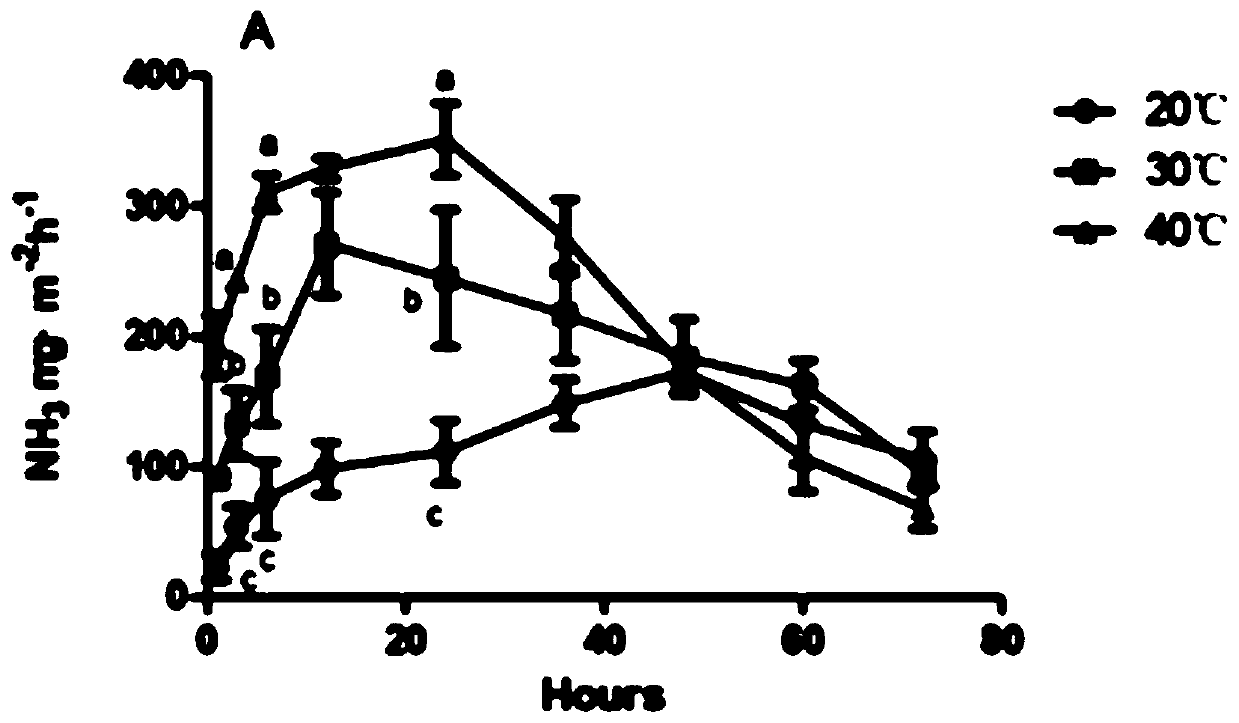

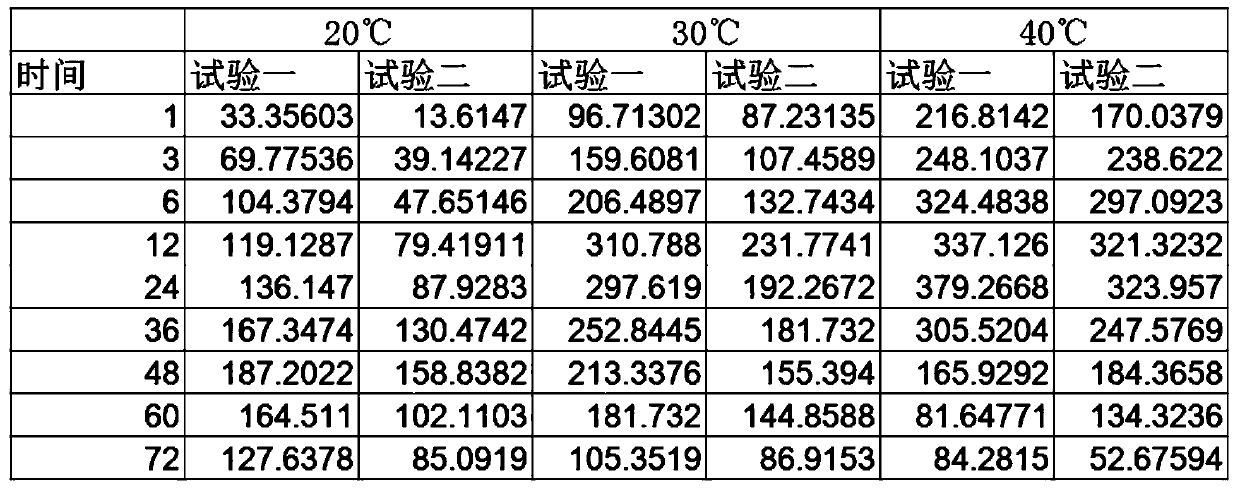

[0034] Add 100 mL of 0.05 mol / L H 2 SO 4 Solution, add 50g of feces and 30g of urine respectively in discharge chamber 2 and mix well. The water bath 6 adjusts the temperature of the excrement and urine in the discharge chamber 2 to 20° C., and the flow meter is adjusted to a flow rate of 0.5 L / min. The fermentation time lasts 72h, and the H in the outlet acid absorber 3 is replaced and collected at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h after the fermentation starts. 2 SO 4 solution. After two experiments, the first experiment determined that the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 33.3, 69.7, 104.3, 119.1, 136.1, 167.3 , 187.2, 164.5, 127.6 (mg). In the second experiment, the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 13.6, 39.1, 47.6, 79.4, 87.9, 130.4, 158.8, 102.1, 85.1 (mg).

Embodiment 2

[0036] Add 100 mL of 0.05 mol / L H 2 SO 4 Solution, add 50g of feces and 30g of urine respectively in discharge chamber 2 and mix well. The water bath 6 adjusts the temperature of the excrement and urine in the discharge chamber 2 to 30° C., and the flow meter is adjusted to a flow rate of 0.5 L / min. The fermentation time lasts 72h, and the H in the outlet acid absorber 3 is replaced and collected at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h after the fermentation starts. 2 SO 4solution. After two experiments, the first experiment determined that the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 96.7, 159.6, 206.4, 310.7, 297.6, 252.8 , 213.3, 181.7, 105.3 (mg). In the second experiment, the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 87.2, 107.4, 132.7, 231.7, 192.2, 181.7, 155.3, 144.8, 86.9 (mg). ...

Embodiment 3

[0038] Add 100 mL of 0.05 mol / L H 2 SO 4 Solution, add 50g of feces and 30g of urine respectively in discharge chamber 2 and mix well. The water bath 6 adjusts the temperature of the excrement and urine in the discharge chamber 2 to 40° C., and the flow meter is adjusted to a flow rate of 0.5 L / min. The fermentation time lasts 72h, and the H in the outlet acid absorber 3 is replaced and collected at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h after the fermentation starts. 2 SO 4 solution. After two experiments, the first experiment determined that the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 216.8, 248.1, 324.4, 337.1, 379.2, 305.5 , 165.9, 81.6, 84.2 (mg). In the second experiment, the amount of ammonia gas discharged per square meter per hour at the nodes of 1h, 3h, 6h, 12h, 24h, 36h, 48h, 60h, and 72h was 170, 238.6, 297.1, 321.3, 323.9, 247.5, 184.3, 134.3, 52.6 (mg).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com