Blast-furnace hot blast stove coal gas abnormal component diagnosis method

A technology of gas composition and diagnosis method, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of long-term rest, combustion or explosion of hot blast stoves, and achieve safe operation, short diagnosis time, and production impact. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described.

[0014] A method for diagnosing abnormal components of blast furnace hot blast stove gas, the diagnostic steps are:

[0015] In the first step, when the test result of the hot stove gas online analyzer 3 continues to show CO > 2000ppm abnormality, the instrument professional will first confirm the test equipment, and conduct manual sampling to analyze the gas composition, and check the test results of the online analyzer;

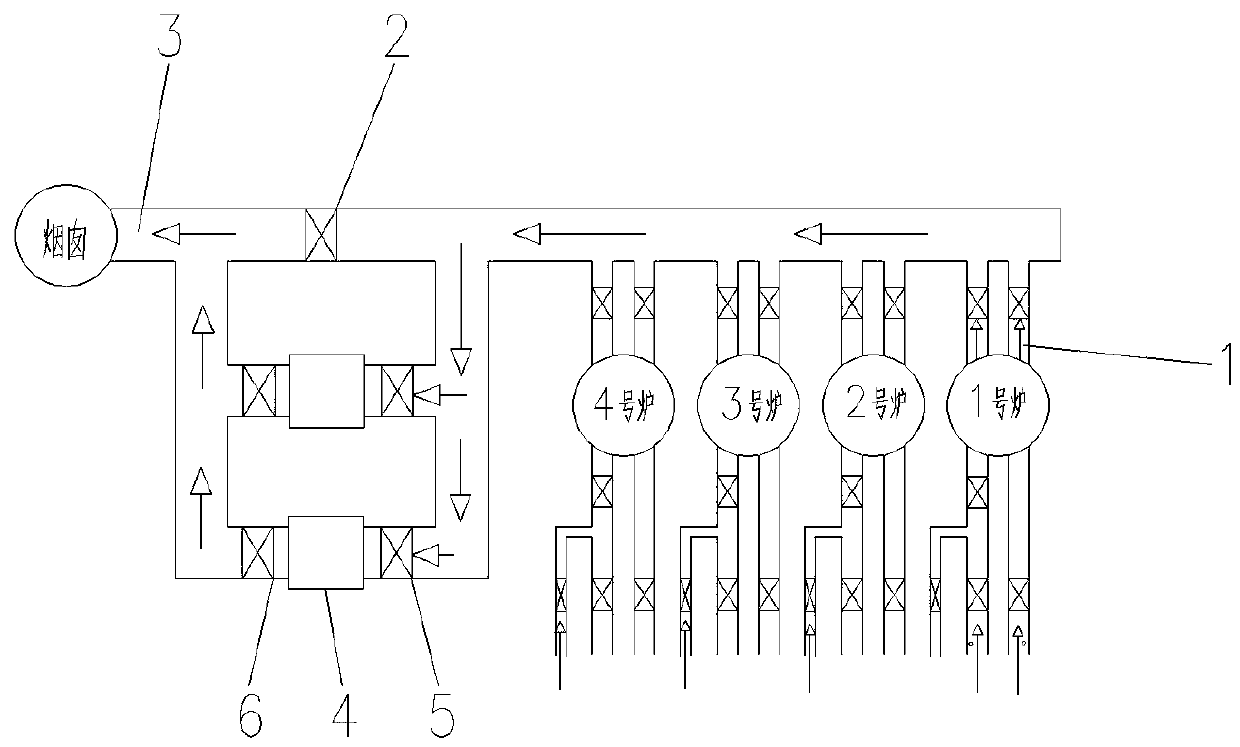

[0016] The second step is to conduct experiments to confirm the possible existence of gas preheater failure punctures or weld bursts in the waste heat recovery system, which may cause gas leakage and affect the abnormal composition of the gas. Fully open the gas preheater 4 bypass valve 2, and then turn off the gas The inlet and outlet valves (5, 6) before and after the preheater are tested for gas without passing through the preheater; if the test results of the gas on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap