Design method of graphic editing interface for wire saw machine numerical control system

A technology of graphic editing and numerical control system, applied in general control system, control/regulation system, program control in sequence/logic controller, etc., can solve the problem of limiting the wide use of wire saw machines, poor human-computer interaction experience, and beginners getting started. Difficulties and other problems, to achieve the effect of improving the effectiveness and accuracy of editing, eliminating the cumbersome code recognition, and improving interface interactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

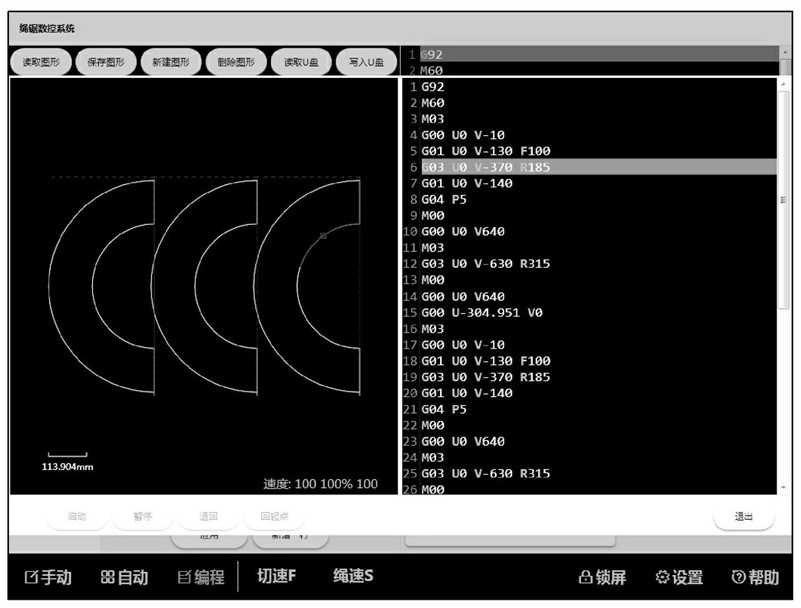

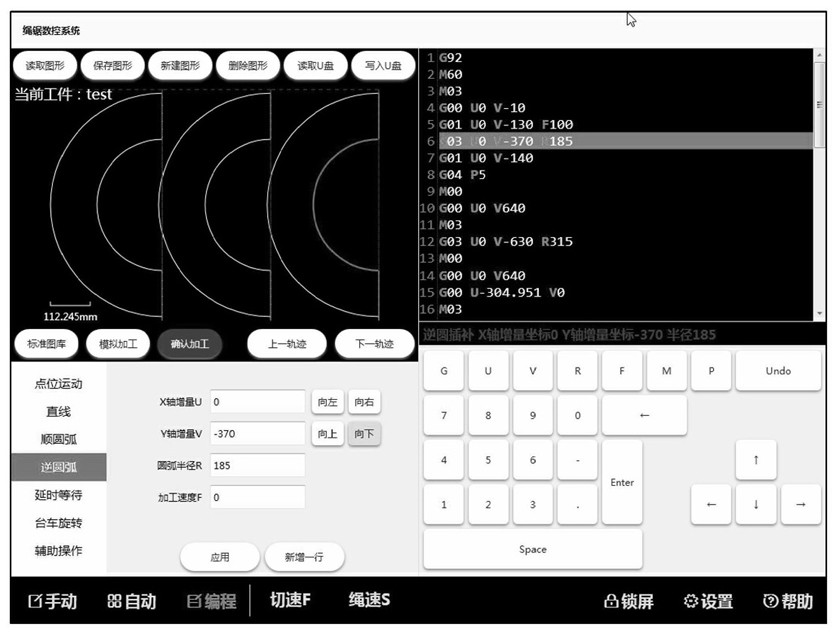

[0016] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that a graphic editing interface design method of the numerical control system of a wire saw machine is applied to the editing interface of the numerical control control system of a wire saw machine, including an editing main interface, and the editing main interface is from left to right. is divided into a first functional area and a second functional area; the first functional area is divided into a graphics display area and a conventional command operation area from top to bottom; the second functional area is divided into a program code presentation area from top to bottom , code comment area and soft keyboard for editing;

[0017] The graphic display area includes a graphic area for graphic presentation, the graphic area is marked with the name and graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com