Fuzzy DCD-based wet metallurgy dense washing process fault diagnosis method

A dense washing, hydrometallurgical technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of many process parameters, difficult fault diagnosis, and complex hydrometallurgical production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

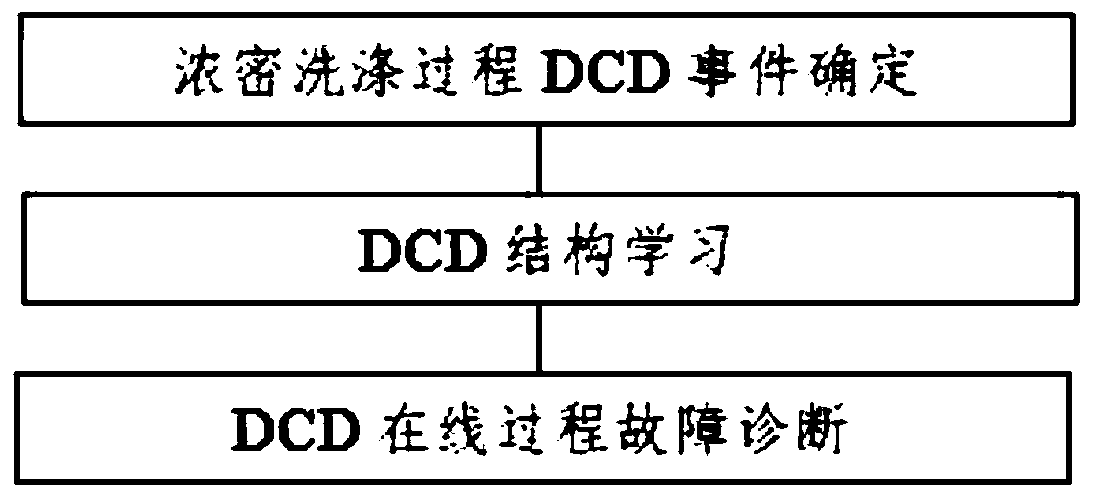

[0096] This embodiment provides a method for fault diagnosis of hydrometallurgical dense washing process based on fuzzy DCD (Dynamic Causality Diagram, dynamic causality diagram), such as figure 2 shown, including the following steps:

[0097] A1. Determination of DCD events in the dense washing process: determine the DCD events in the dense washing process, and clarify the event variables involved in the hydrometallurgical dense washing process. The DCD events include node events and intermediate events;

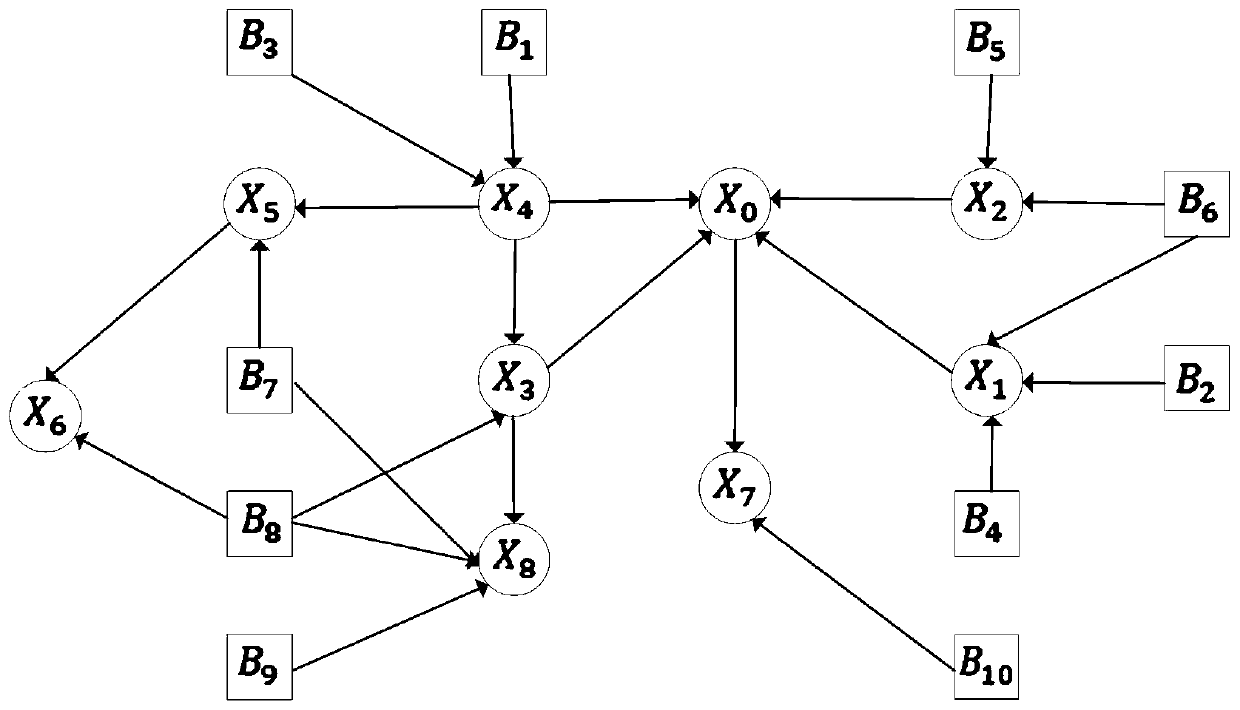

[0098] A2, DCD structure learning: according to the DCD event and event variables, determine the causal relationship and connection probability between the event variables, and establish a causal graph model;

[0099] A3. DCD online process fault diagnosis: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com