Spraying production monitoring data storage and feature analysis method and device

A technology of monitoring data and feature analysis, applied in the direction of neural learning methods, genetic rules, biological neural network models, etc., can solve the problems of poor analysis effect and low accuracy of spraying production monitoring data, achieve good data analysis effect, eliminate Useless features, fitness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

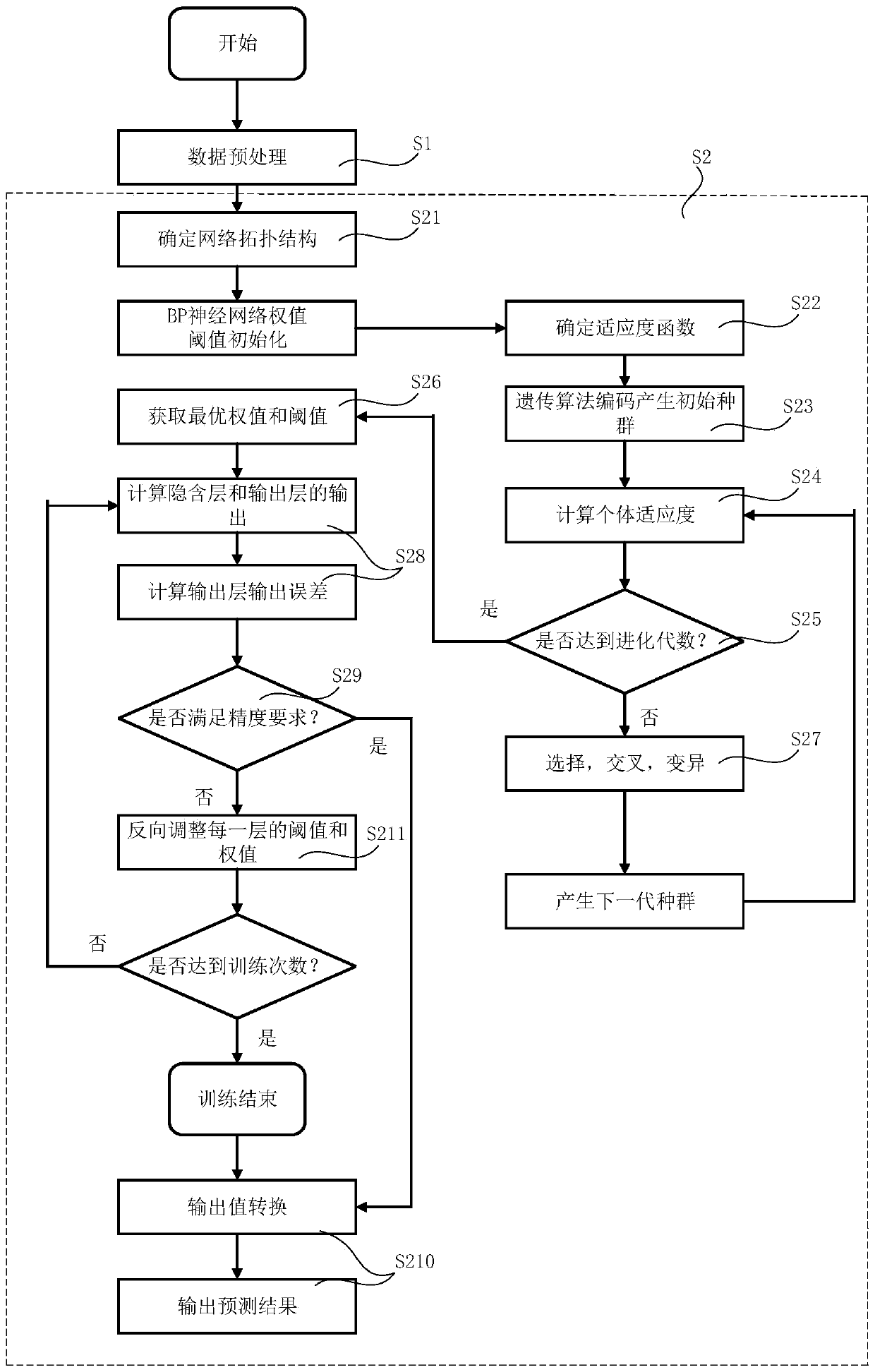

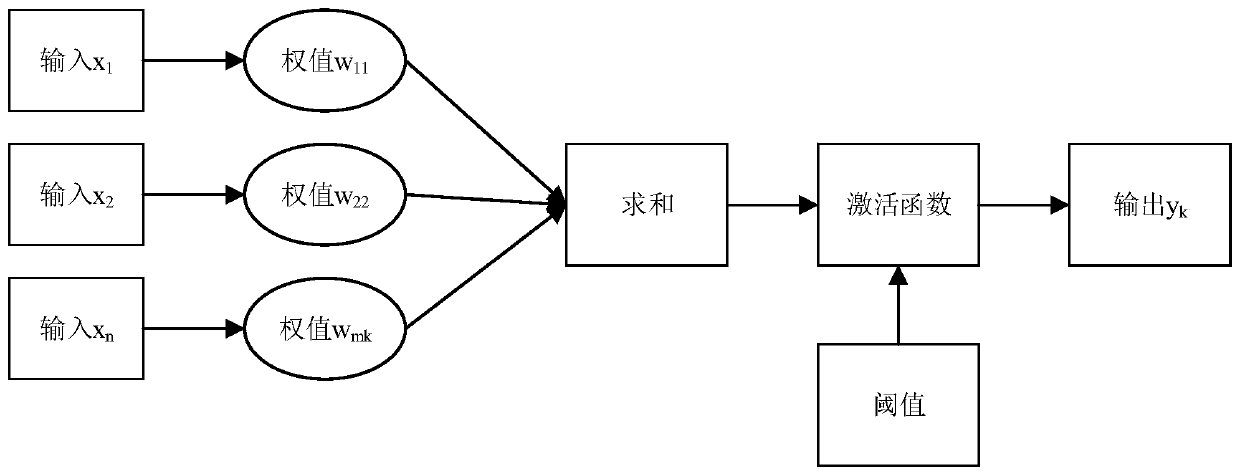

Method used

Image

Examples

Embodiment 1

[0122] The inventor of this case found through research that the daily output of the spraying workshop is relatively large. During the investigation, it was found that the unqualified products were basically unqualified in appearance, so data mining and analysis were carried out on the appearance quality. Products with unqualified appearance are found to have obvious daily production fluctuations and lack of stability. Please refer to Table 1, which counts the data of products that failed the product quality inspection within a week.

[0123] Table 1 Weekly Product Statistical Results Table

[0124]

[0125]

[0126] The mean value and standard deviation related to the unqualified products of the 6 products can be obtained through the calculation in the above table, as shown in Table 2.

[0127] Table 2 Statistical table of mean and standard deviation of unqualified product rate of 6 kinds of products

[0128]

[0129] It is found from Table 2 that the quality inst...

Embodiment 2

[0233] This embodiment provides a method for storing and analyzing characteristics of spraying production monitoring data, and step S0 is added to the method in Embodiment 1. Wherein, step S0: store the monitoring data through the cloud server. In this embodiment, the cloud server is preferably an Alibaba Cloud server, and a development environment is built through Node.js and Express.js frameworks. see Figure 19 , in this embodiment, a non-relational database MongoDB is used for distributed file storage. In the process from workpiece processing to data storage, there will be a large number of sensors to collect current information. This kind of sensor equipment will monitor all the time, and will send data at a certain frequency without interruption to generate a data stream. The MongoDB database will be stored in the form of documents. If it is said that every piece of sensor data is stored in the form of a document, then a large number of documents will be generated, and...

Embodiment 3

[0235] This embodiment provides a storage and feature analysis device for spraying production monitoring data, the device applies the storage and feature analysis method for spraying production monitoring data in embodiment 1 or implementation 2, and includes a preprocessing module and a neural network prediction module .

[0236]The preprocessing module is used to preprocess the monitoring data of spraying production, and includes a missing value processing unit, a normalization unit, a correlation inspection unit, and a data dimensionality reduction unit. The missing value processing unit is used to supplement missing values in monitoring data and obtain a complete monitoring data table. The normalization unit is used to scale the data in the monitoring data table according to a preset ratio to obtain normalized data with a mean of 0 and a standard deviation of 1. The correlation test unit is used to mine the linear correlation coefficient between normalized data. The da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com