Three-dimensional memory and formation method thereof

A memory, three-dimensional technology, applied in the direction of semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of complex three-dimensional memory manufacturing process and high manufacturing cost, reduce the number and the number of etching times, improve the utilization rate, and simplify the manufacturing. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

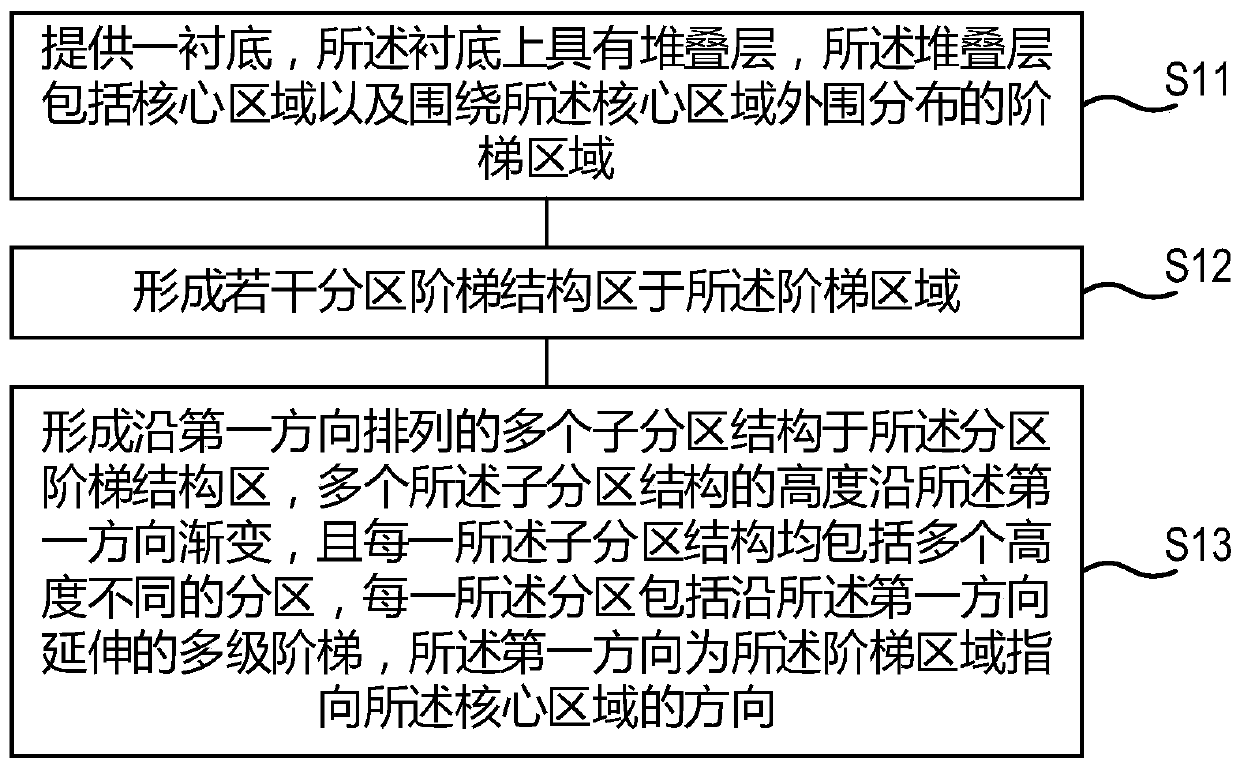

[0040] The specific embodiments of the three-dimensional memory provided by the present invention and the method for forming the same will be described in detail below with reference to the accompanying drawings.

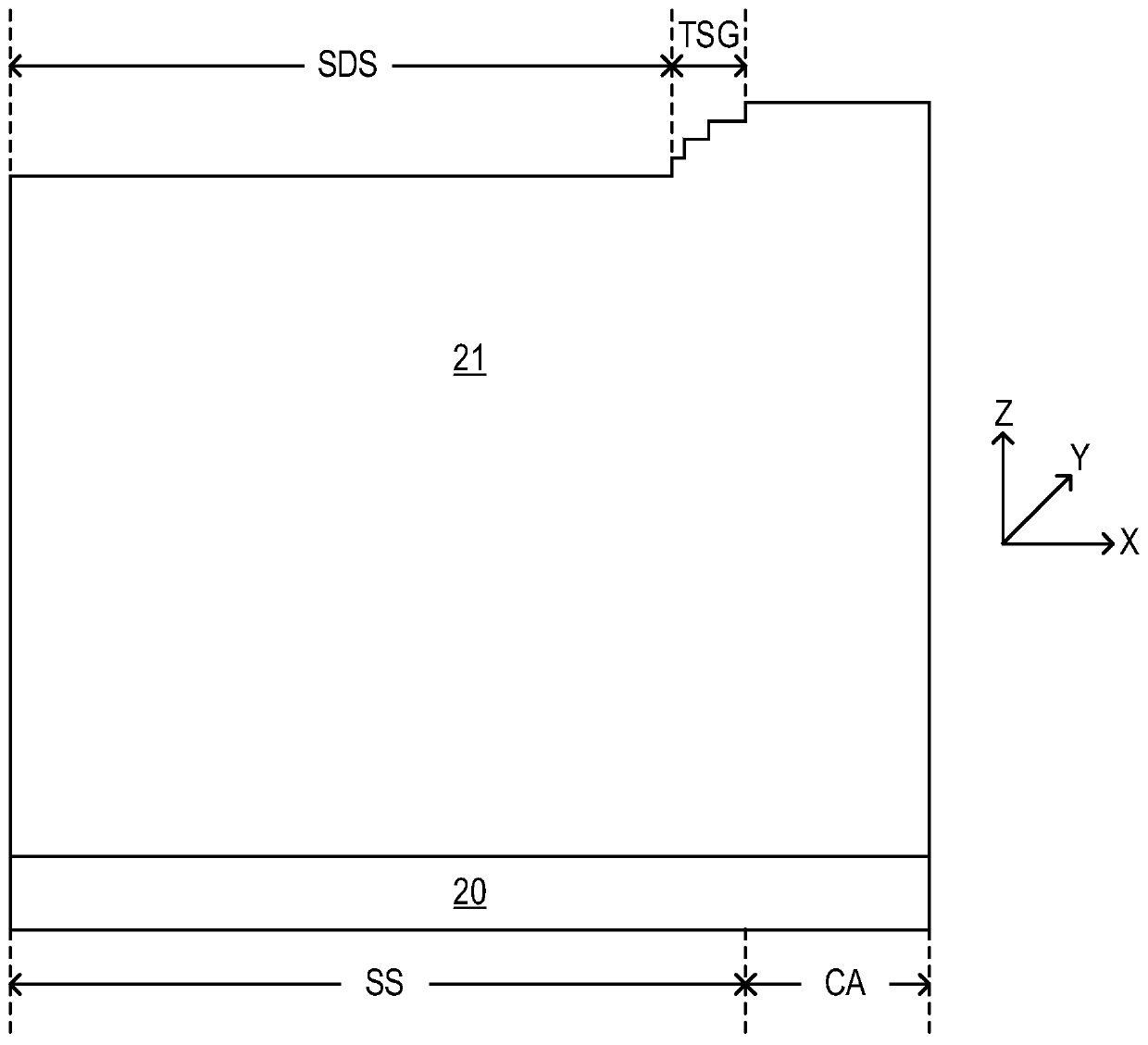

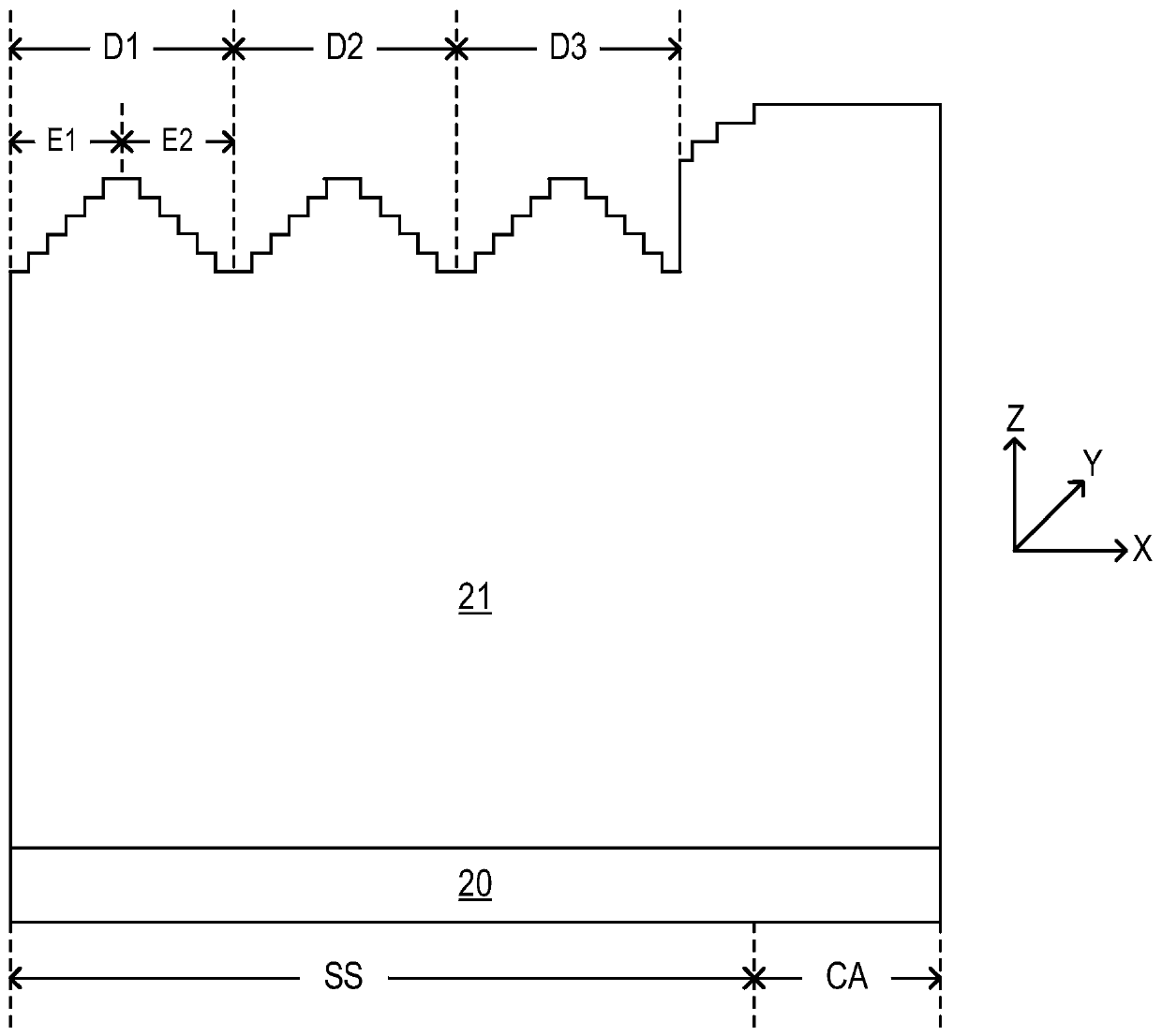

[0041] A three-dimensional memory typically includes a substrate and stacked layers on the substrate, the stacked layers including a core region and a stepped region disposed around the core region. The core area is used for information storage; the stepped area is located at the end of the stack layer, and is used for transmitting control information to the core area, so as to realize the reading and writing of information in the core area.

[0042] The traditional stepped area is a one-way stepped structure. However, as the number of stacked layers in 3D memory continues to increase, the unidirectional stepped structure leads to an increase in the area of the stepped region and a dramatic increase in the manufacturing cost. Based on this, the Staircase Divide S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com