Automatic paper wrapping device for anti-corrosion coating protection of oil and gas steel pipe ends

A technology of anti-corrosion coating and steel pipe, which is applied in packaging, transportation and packaging, thin material processing, etc., can solve the problems of labor-consuming, time-consuming, uneven quality, low efficiency, etc., and achieve accurate positioning, uniform quality, and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

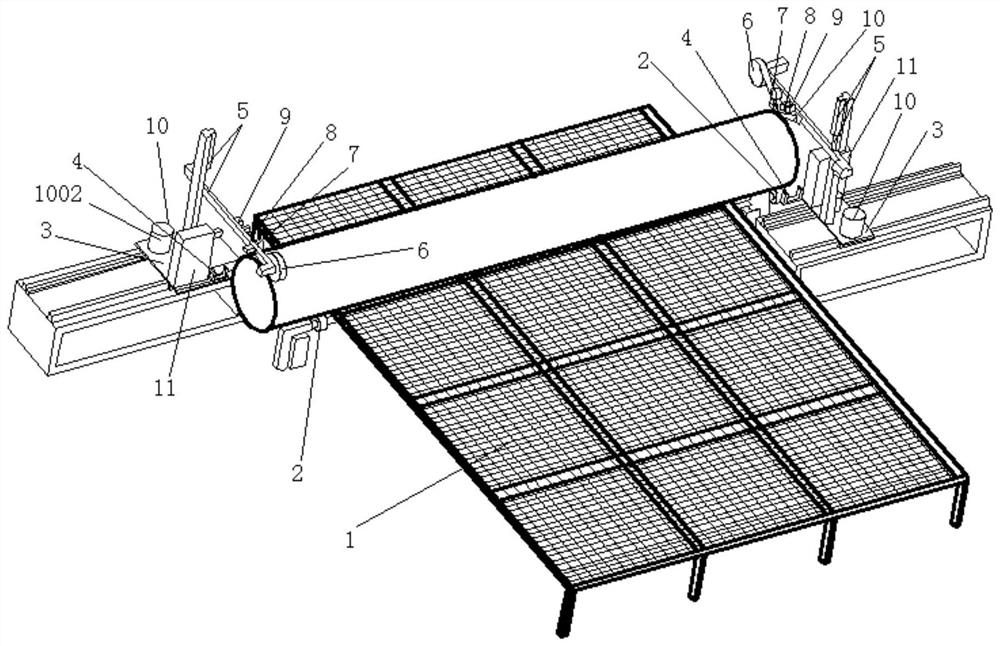

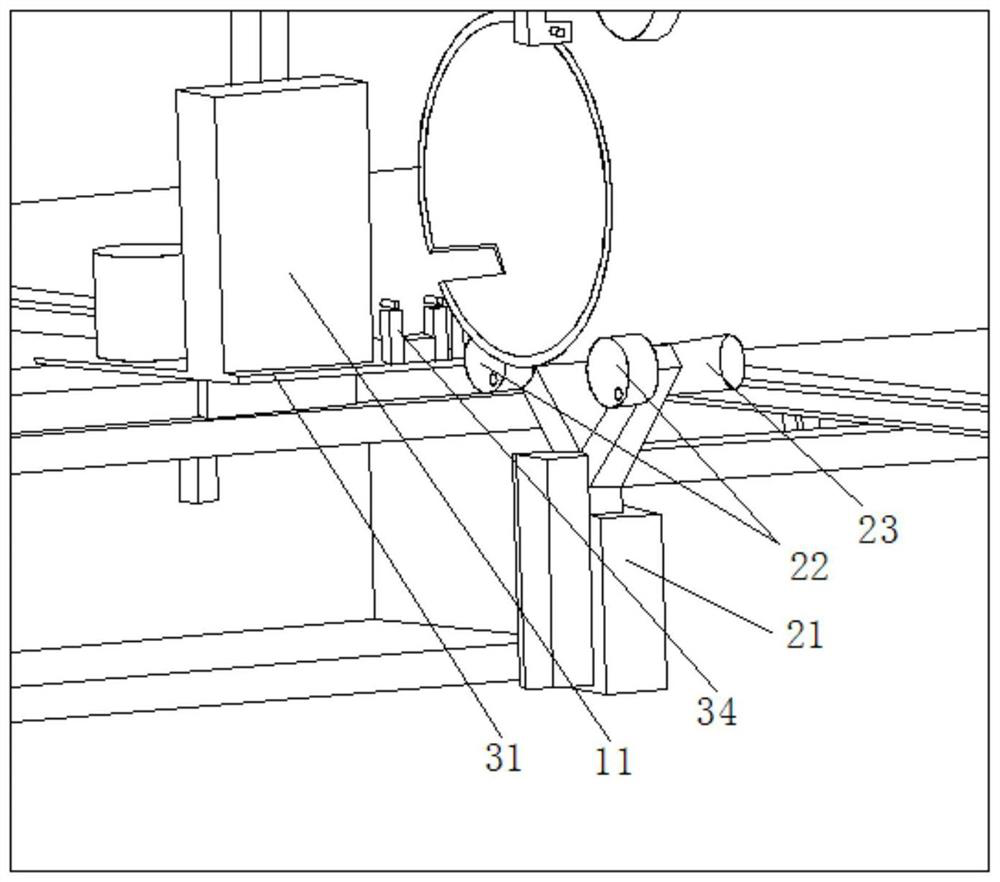

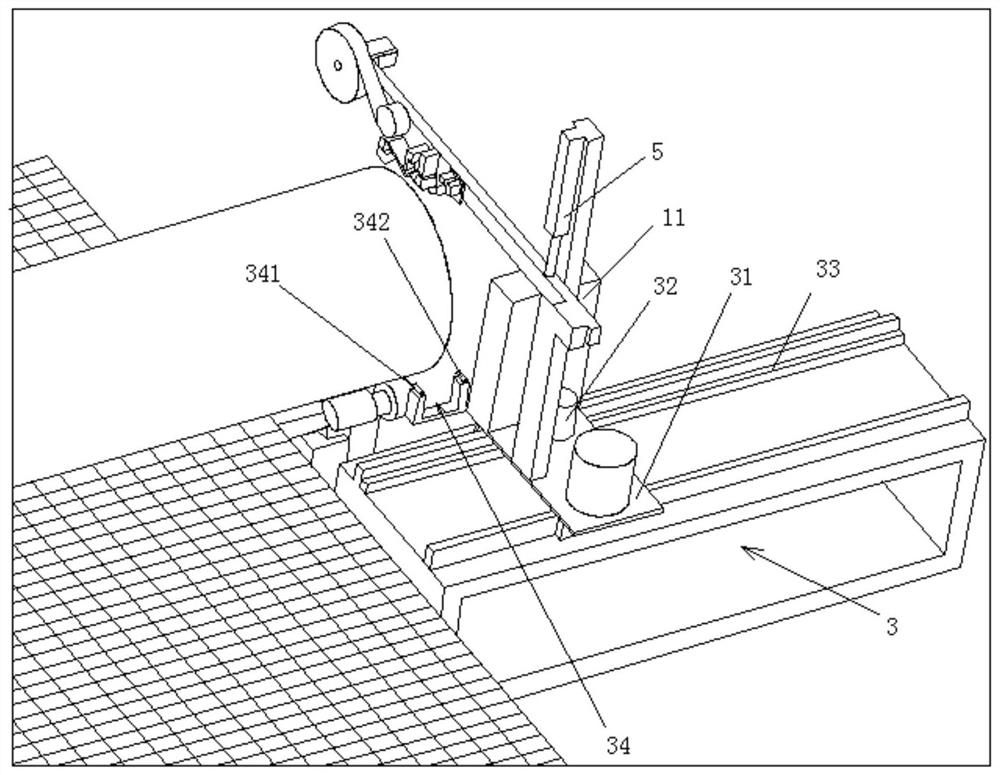

[0032] Attached below Figure 1-13 Specific examples of the present invention are described.

[0033] Automatic wrapping device for anti-corrosion coating protection at the ends of oil and gas steel pipes, (such as figure 1 Shown) has a slope conveying carrier plate 1, a steel pipe roller bracket 2, an axial movement mechanism 3, a brake mechanism 4, a lifting arm assembly 5, and a paper winding system mounted on the lifting arm assembly 5. Specifically, such as figure 1 In the shown embodiment, the left and right symmetrical outer sides of the conveying carrier 1 and the steel pipe roller bracket 2 are respectively equipped with a set of axial movement mechanism 3, brake mechanism 4, lifting arm assembly 5, and paper winding system, and the two sets of systems are simultaneously Run the job, or run the job individually. Among them, in order to save energy consumption, gravity is used to convey steel pipes, eliminating the need to set up a huge hoisting mechanism: the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com