Connection joint of prefabricated floor slab and beam

A connection node and prefabricated technology, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of difficult to adapt to the rapid construction of light-weight housing structure floor slabs, no insulation and sound insulation, air purification and waterproofing, and complex connection methods. To achieve the effect of shortening the construction period, good waterproofness, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

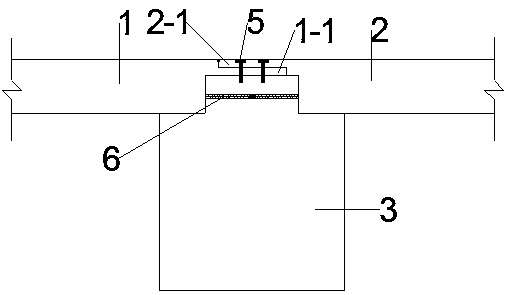

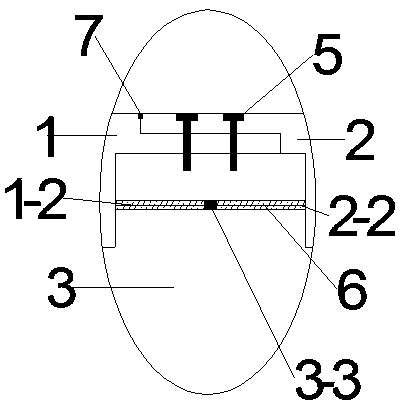

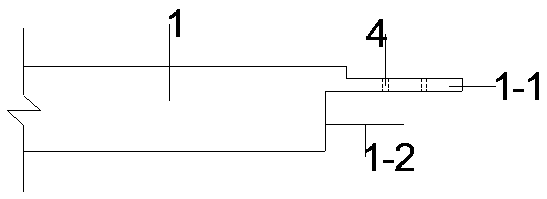

[0018] Example: such as Figure 1-Figure 5 As shown, a connection node between a prefabricated floor and a beam includes a first floor 1, a second floor 2, a beam 3, reserved bolt holes 4, high-strength bolts 5, cast-in-place concrete 6, and a water-expanding agent 7. One side of the first floor 1 is prefabricated with the first floor extension rib 1-1 outward, and the first floor extension rib 1-2 is reserved at the lower part of the same side, and there are reserved bolt holes 4 inside the first floor extension rib ; One side of the second floor 2 outwardly prefabricates the second floor extension rib 2-1, and the second floor extension rib 2-2 is reserved at the lower part of the same side, and the second floor extension rib 2-1 has Bolt holes 4 are reserved; the upper part of the beam 3 is prefabricated outwardly with a rectangular rib 3-1 extending outward, and a built-in steel bar channel 3-2 is reserved inside, and a built-in steel bar sleeve 3 is prefabricated inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com