Automatic power test machine for ultra-thin heat pipe and working method thereof

An automatic power, ultra-thin heat pipe technology, applied in the direction of material thermal development, instrumentation, program control in sequence/logic controllers, etc., can solve the problems of difficult to simulate the gravity environment of heat pipes, mechanical damage of ultra-thin heat pipes, and high labor costs. Achieve the effect of improving test efficiency, saving labor costs and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

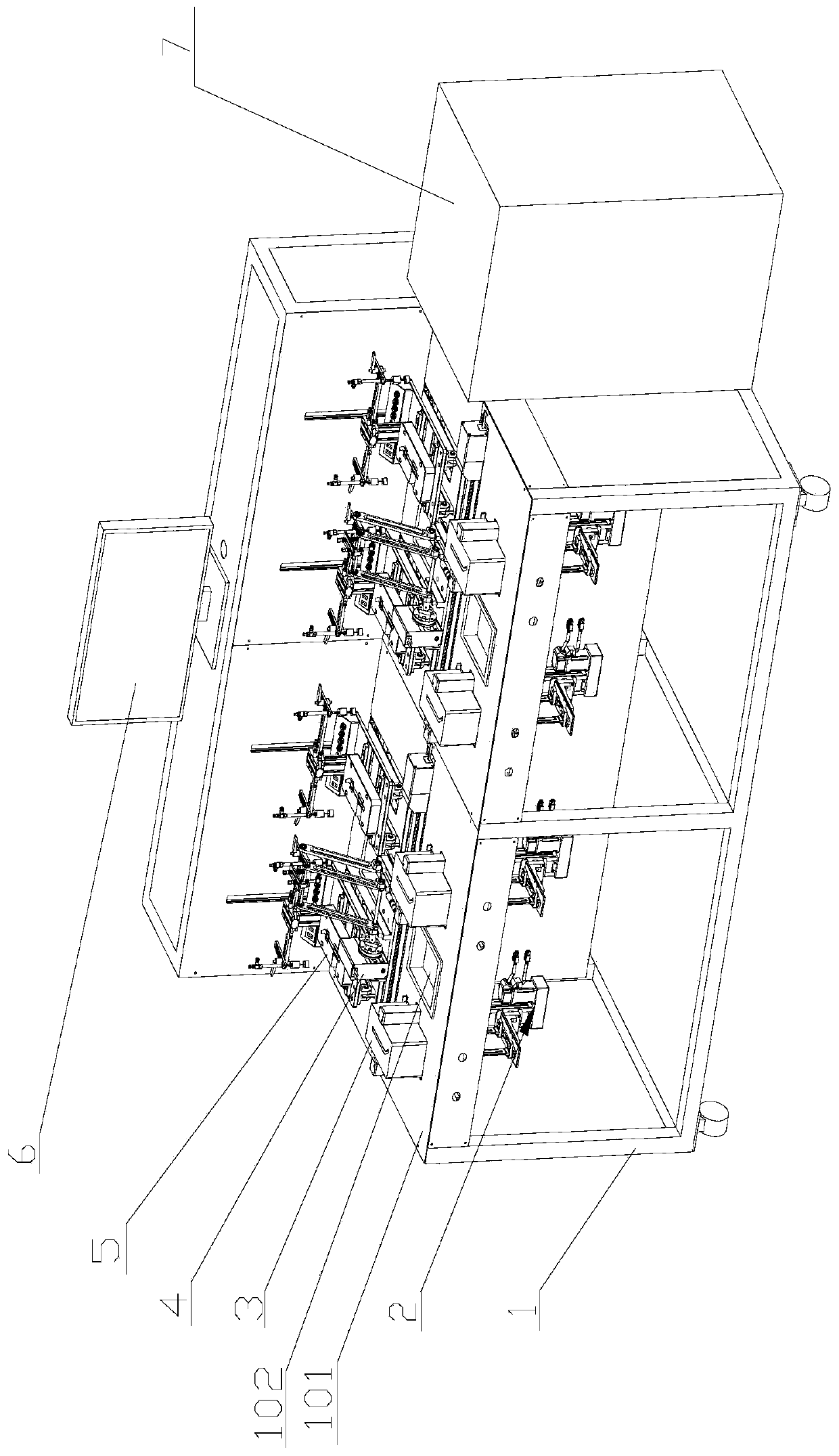

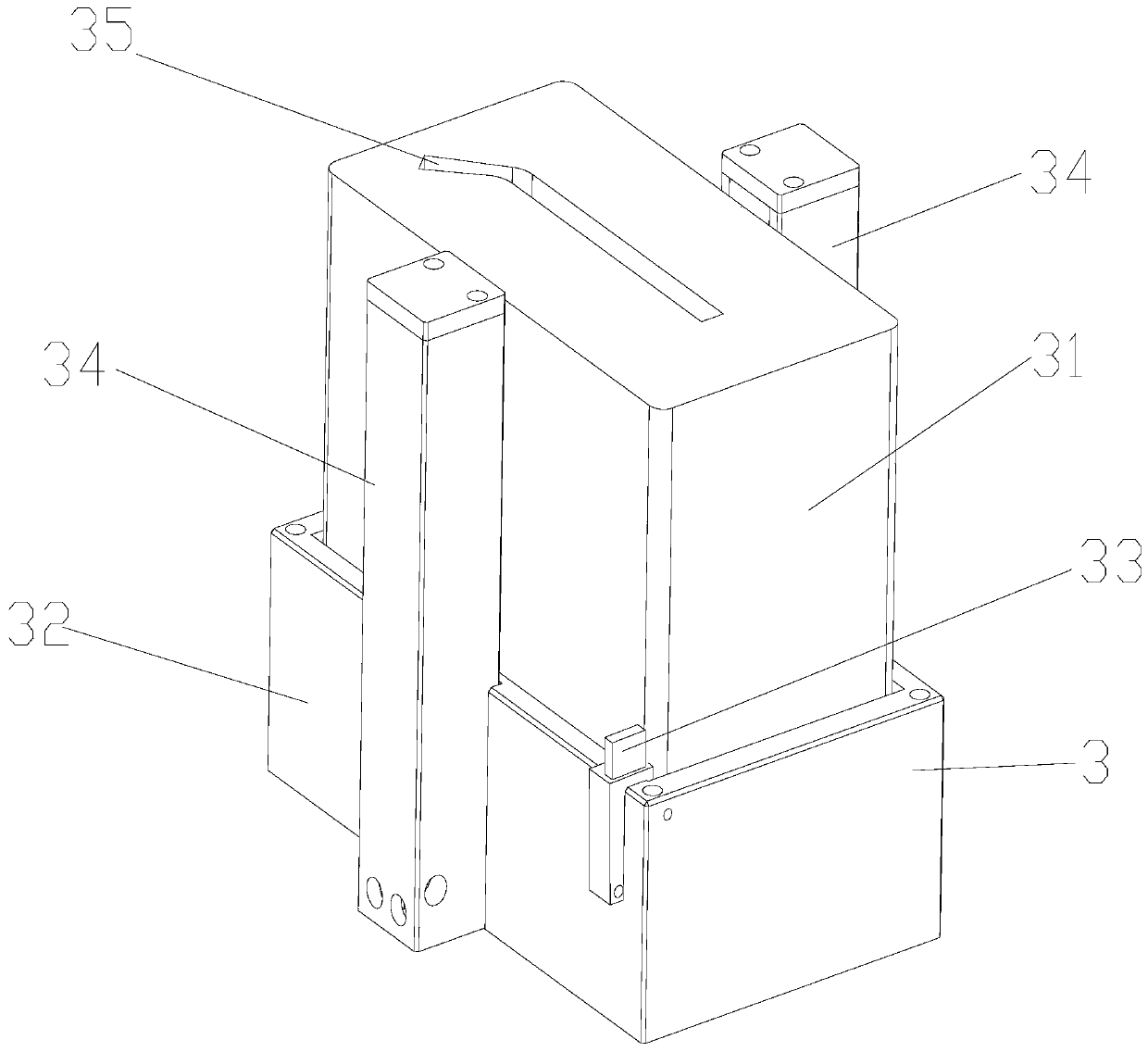

[0029] Such as figure 1 As shown, this embodiment provides an automatic power testing machine for ultra-thin heat pipes, including a frame 1, a material lifting mechanism 2, a material height detection mechanism 3, a feeding mechanism 4, a test fixture mechanism 5, a program-controlled DC power supply, a computer 6, and a constant temperature Water tank 7, temperature acquisition card and PLC controller.

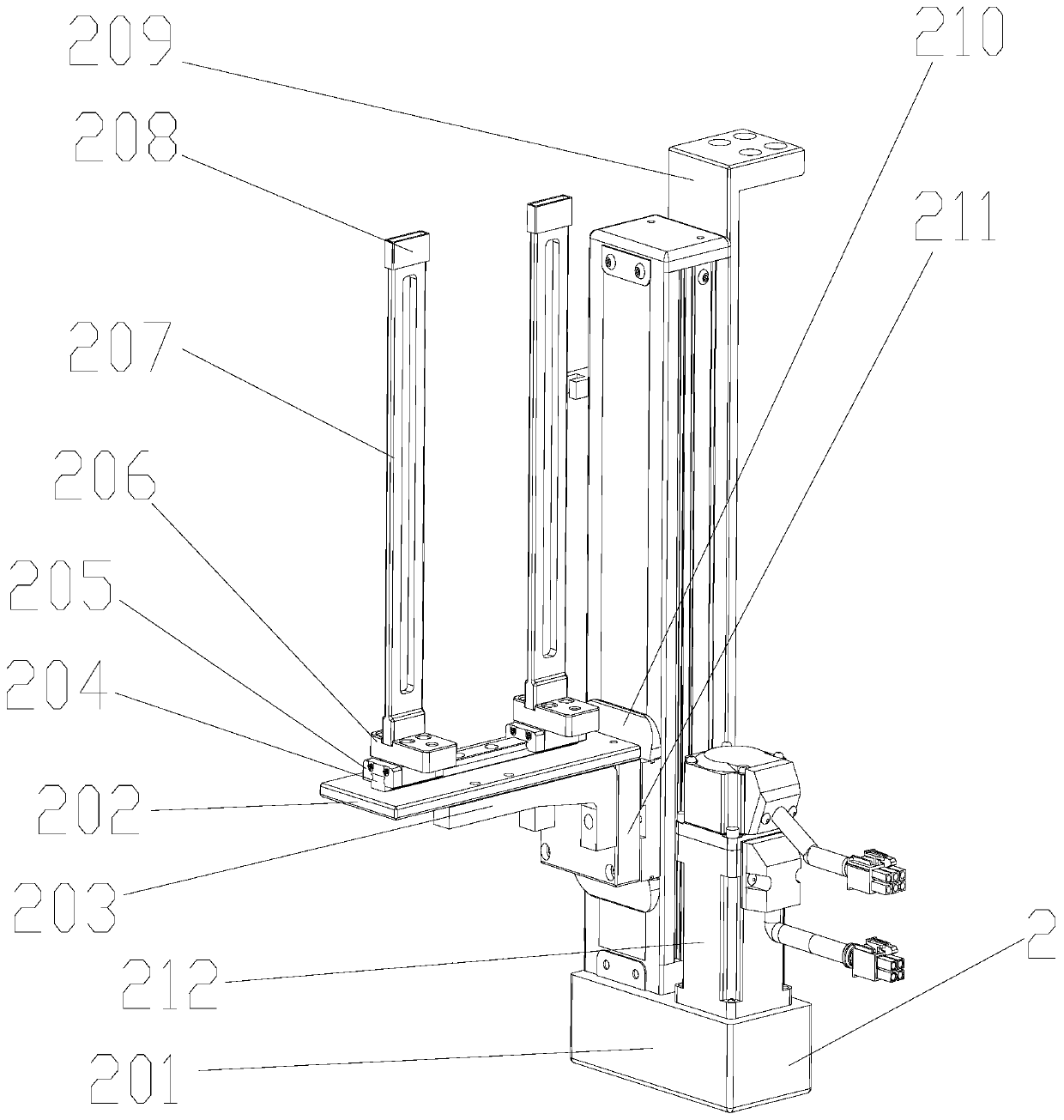

[0030] Such as figure 1 with figure 2 As shown, the frame is provided with a base plate 101, the base plate is provided with a groove 102 for placing qualified products and unqualified products, and the material lifting mechanism includes a vertical module 201, a support column bottom plate 202, a reinforcing rib 203, and a horizontal guide rail 204 , horizontal guide rail slider 205, ejector pin bottom plate 206, ejector pin 207, magnet replacement block 208, material placement back plate 209, vertical module slider 210, rib mounting block 211 and vertical motor 212, mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com