Gradient composite magnetic separation high-frequency vibration control system

A high-frequency vibration and control system technology, applied in general control systems, control/regulation systems, high-gradient magnetic separators, etc., can solve problems such as lack of vibration regulation efficiency, reduced magnetic separation efficiency, and reduced magnetic separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

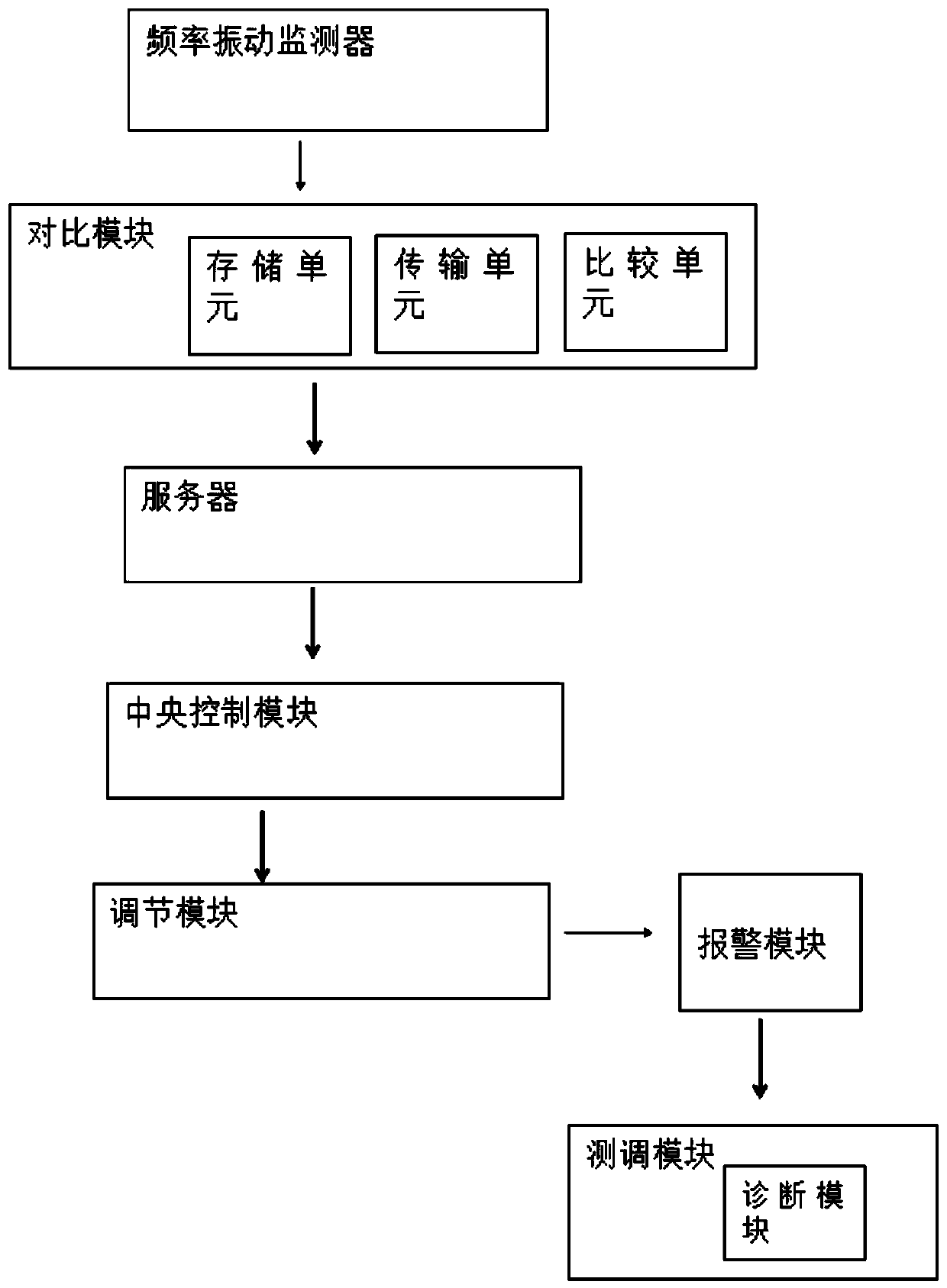

[0024] Such as figure 1 As shown, the gradient compound magnetic separation high-frequency vibration control system of the present embodiment includes a frequency vibration monitor, the frequency vibration detector is connected with a comparison module, the comparison module is connected with a server, the server is connected with a central control module, and the central control module It is connected with the adjustment module, the adjustment module is connected with the alarm module, and the alarm module is connected with the measurement and adjustment module;

[0025] The comparison module includes a storage unit, a transmission unit and a comparison unit. The comparison unit compares the information transmitted by the frequency vibration detector with the safety value. When the transmission value is greater than the safety value, the transmission unit transmits the information to the server, and the storage module can automatically store the information. ;

[0026] The a...

Embodiment 2

[0035] Such as figure 1 As shown, the gradient compound magnetic separation high-frequency vibration control system of the present embodiment includes a frequency vibration monitor, the frequency vibration detector is connected with a comparison module, the comparison module is connected with a server, the server is connected with a central control module, and the central control module It is connected with the adjustment module, the adjustment module is connected with the alarm module, and the alarm module is connected with the measurement and adjustment module;

[0036] The comparison module includes a storage unit, a transmission unit and a comparison unit. The comparison unit compares the information transmitted by the frequency vibration detector with the safety value. When the transmission value is greater than the safety value, the transmission unit transmits the information to the server, and the storage module can automatically store the information. ;

[0037] The a...

Embodiment 3

[0045] Such as figure 1 As shown, the gradient composite magnetic separation high-frequency vibration control system of the present embodiment includes a frequency vibration monitor, and the frequency vibration detector is connected with a comparison module, the comparison module is connected with a server, the server is connected with a central control module, and the central control module It is connected with the adjustment module, the adjustment module is connected with the alarm module, and the alarm module is connected with the measurement and adjustment module;

[0046]The comparison module includes a storage unit, a transmission unit and a comparison unit. The comparison unit compares the information transmitted by the frequency vibration detector with the safety value. When the transmission value is greater than the safety value, the transmission unit transmits the information to the server, and the storage module can automatically store the information. ;

[0047] T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap