Small-sized combustion engine power rock drill

A rock drilling rig and internal combustion engine technology, applied in the field of small internal combustion engine powered rock drilling rigs, can solve problems such as excessive dust, high noise, and high labor intensity, and achieve the effects of good overall stability, low energy consumption, and flexible and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

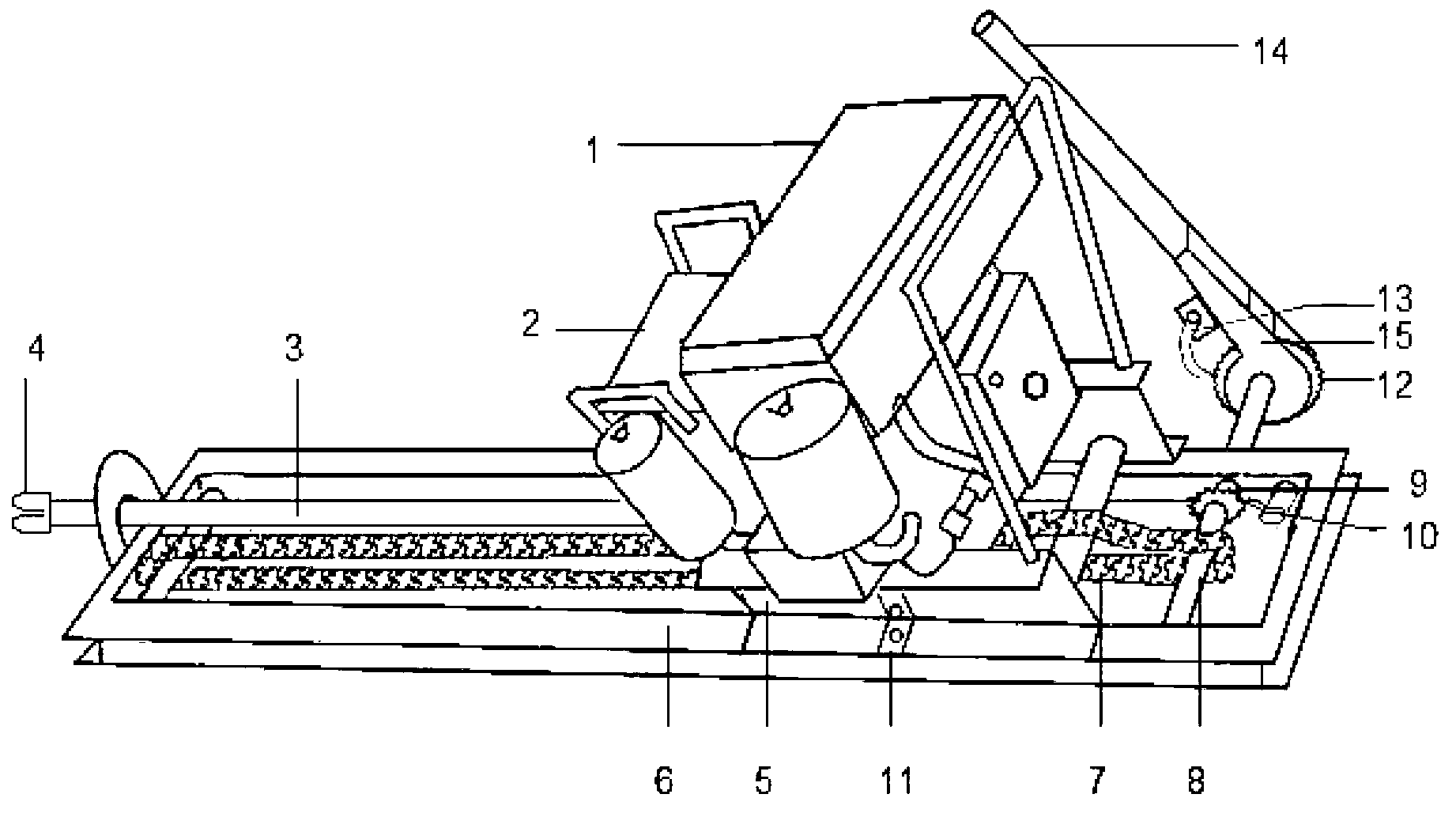

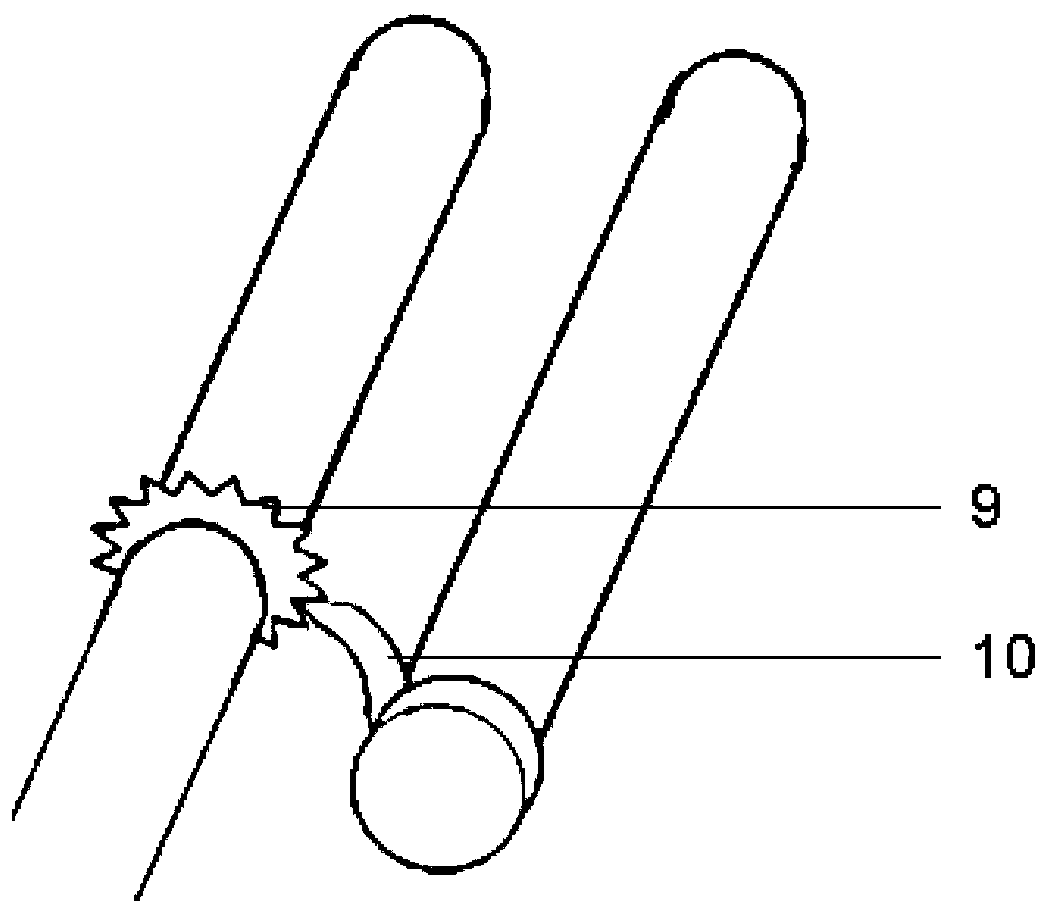

[0019] Such as figure 1 As shown, a small internal combustion engine powered rock drilling rig consists of an internal combustion engine 1, a reduction box 2, an output main rod 3, a drill bit 4, a trailer 5, a channel steel frame 6, a closed-loop chain 7, a sprocket shaft 8, and a manual force-input rod Mechanism, anti-retreat gear 9, movable anti-retreat claw 10, curved button 11 and sealing water jacket are formed;

[0020] The power output end of the internal combustion engine 1 is meshed with the spline shaft at the rear end of the reduction box 2 through a spline keyboard, and the reduction box 2 is a two-stage reduction box; the front end of the output main rod 3 is equipped with a drill bit 4, and the rear end is connected with the output shaft of the reduction box 2 ; internal combustion engine 1 and reduction box 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com