Hollow fiber nanofiltration membrane and preparation process thereof

A nanofiltration membrane and fiber technology, which is applied in the field of hollow fiber nanofiltration membrane and its preparation, can solve the problems of long dissolution time, long process flow, and short storage time when easy to be closed, achieve uniform pore size distribution of the membrane, and solve the problem of long process flow. , the effect of shortening the time of membrane pore retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

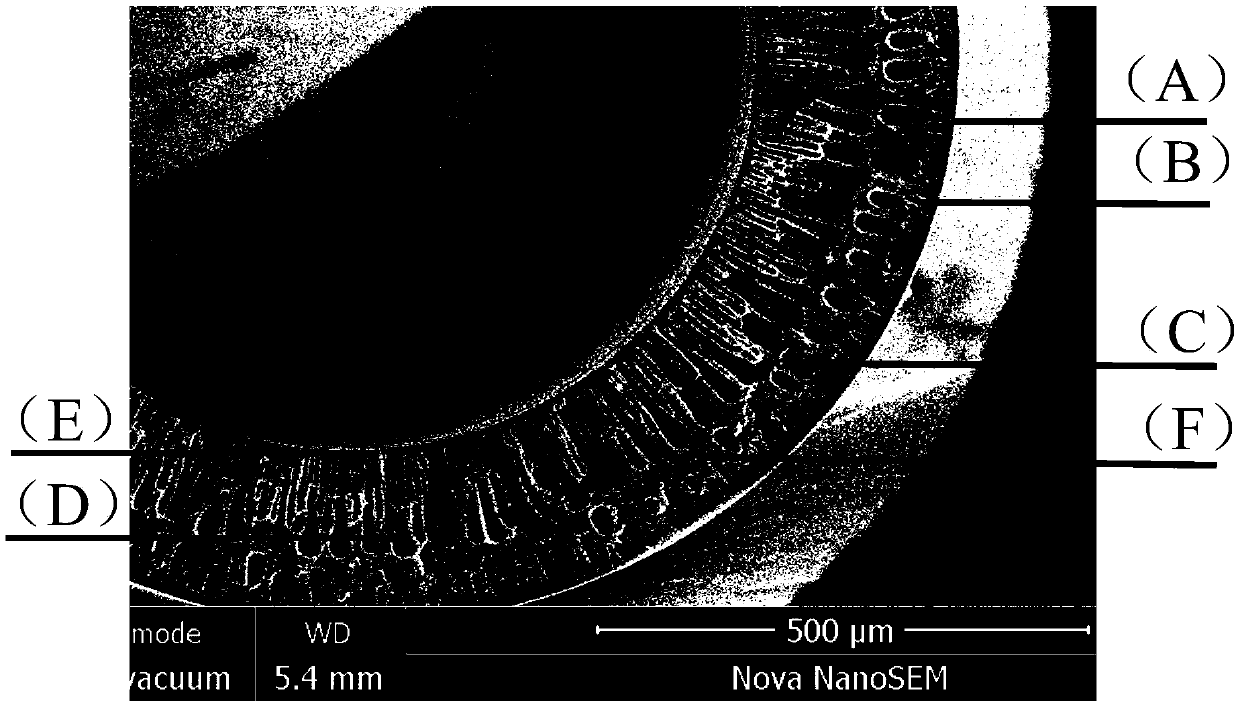

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of preparation method of hollow fiber nanofiltration membrane, concrete steps are:

[0030] 1) Extraction of spinning solution: Put 30 parts by mass of polyethersulfone, 2 parts of pore-forming agent, and 58 parts of organic solvent into the dissolution tank, and stir for 1 hour at 90°C with a crusher at a forward speed of 66 rpm. Stop for 30 seconds, reverse speed 66 rpm, stir at 90°C for 50 minutes, stop for 30 seconds, mix and break and stir for 4 hours to fully dissolve and swell until completely dissolved into spinning solution;

[0031] 2) Spinning: pass the spinning solution in step 1) through a 300-mesh filter membrane to remove impurities, and then enter a vacuum degassing device with a vacuum degree of -0.08 MPa, and pretreatment at a temperature of 90°C to remove air bubbles for 12 minutes; The impurity-free spinning liquid is made into a hollow fiber nanofiltration membrane nascent membrane by dry-jet wet spinning;

[0032] 3) Curing: T...

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of hollow fiber nanofiltration membrane, concrete steps are:

[0035] 1) Extraction of spinning solution: put 30 parts by mass of polyethersulfone, 12 parts of pore-forming agent, and 58 parts of organic solvent into the dissolution tank, and stir for 1 hour at 90°C with a crusher at a forward speed of 133 rpm. Stop for 60 seconds, reverse speed 133 rpm, stir at 90°C for 50 minutes, mix and break and stir for 4 hours to fully dissolve and swell until completely dissolved into spinning solution;

[0036] 2) Spinning: pass the spinning solution in step 1) through a 300-mesh filter membrane to remove impurities, and then enter a vacuum defoaming device with a vacuum degree of -0.1 MPa, and pretreat the air bubbles at a temperature of 90°C for 10 minutes; The impurity-free spinning liquid is made into a hollow fiber nanofiltration membrane nascent membrane by dry-jet wet spinning;

[0037] 3) Curing: The hollow fiber nanofiltratio...

Embodiment 3

[0039] Embodiment 3: a kind of preparation method of hollow fiber nanofiltration membrane, concrete steps are:

[0040] 1) Extraction of spinning solution: put 40 parts by mass of polyethersulfone, 12 parts of pore-forming agent, and 68 parts of organic solvent into the dissolution tank, and stir for 2 hours at 90°C with a crusher at a forward speed of 133 rpm. Stop for 60 seconds, reverse speed 133 rpm, stir at 90°C for 59 minutes, stop for 30 seconds, mix and break and stir for 6 hours to fully dissolve and swell until completely dissolved into spinning solution;

[0041] 2) Spinning: Pass the spinning liquid in step 1) through a 400-mesh filter membrane to remove impurities, and then enter a vacuum degassing device with a vacuum degree of -0.06 MPa, and pretreat the air bubbles at a temperature of 90°C for 14 minutes; The impurity-free spinning liquid is made into a hollow fiber nanofiltration membrane nascent membrane by dry-jet wet spinning;

[0042] 3) Curing: The hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com