A kind of preparation method of improved composite core body

A composite core, an improved technology, applied in adhesive products, medical science, household appliances, etc., can solve the problems of cumbersome processing technology and high processing cost of composite cores, reduce composite processes, reduce processing costs, and achieve ultra-thin sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

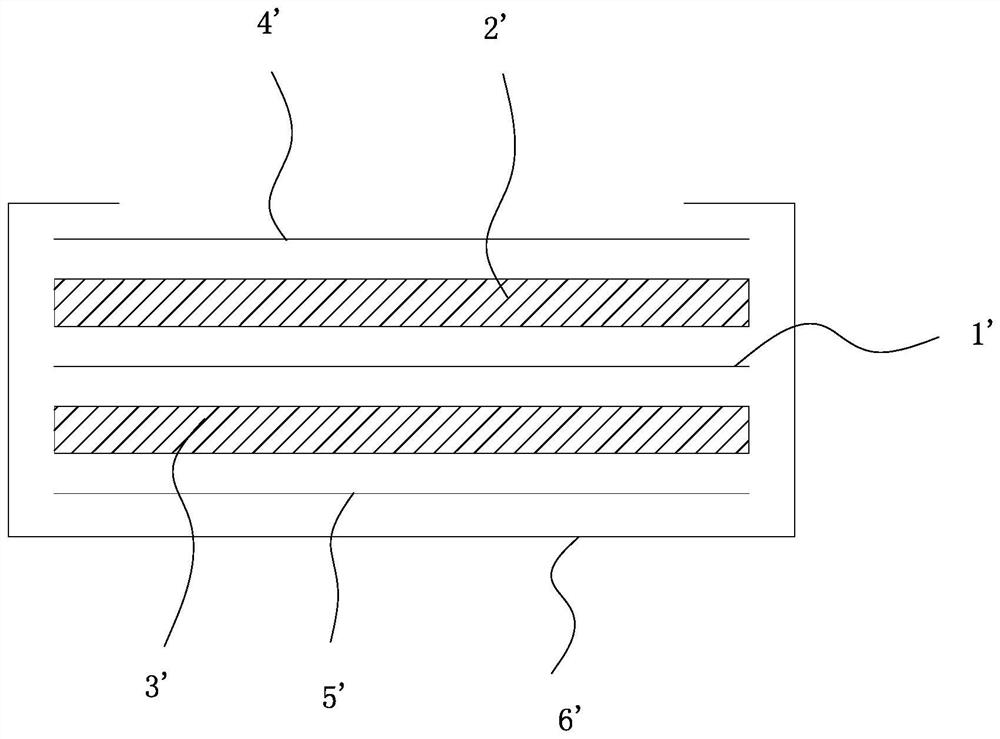

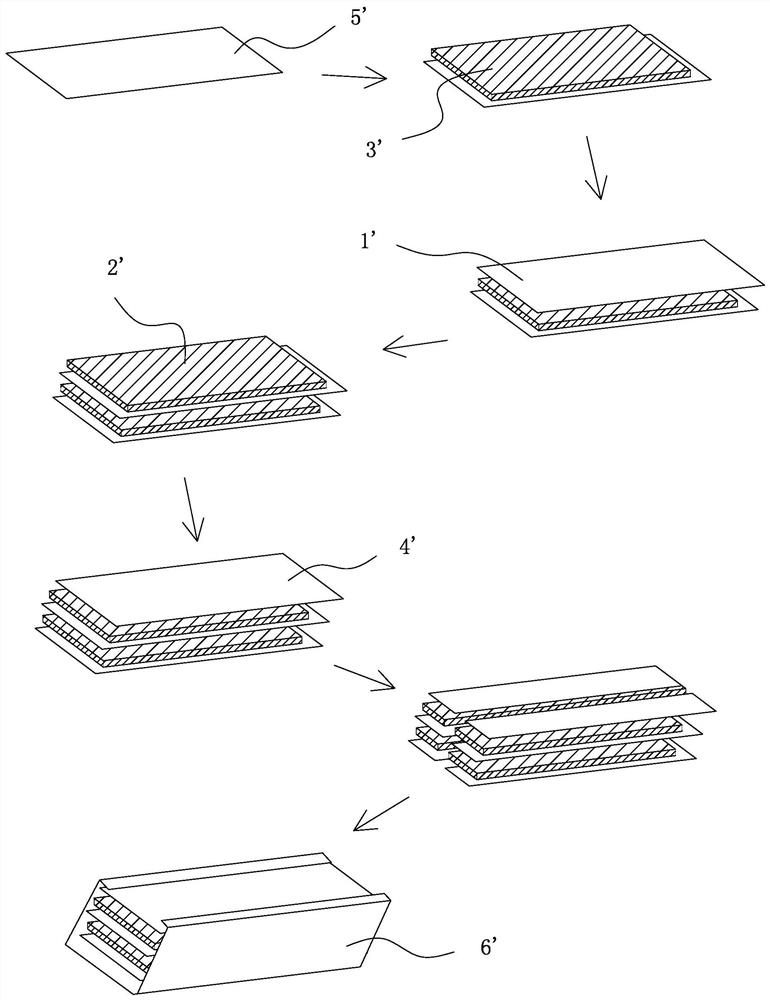

[0028] refer to image 3 and Figure 4 , a preparation method of an improved composite core, comprising the following steps:

[0029] a. Convey a nonwoven fabric 1 in a continuous manner, define the conveying direction along the nonwoven fabric 1 as the longitudinal direction, and define the transverse direction along its width direction, and spray glue on the upper surface of the continuously conveyed nonwoven fabric 1 deal with;

[0030] b. Add polymer water-absorbing resin material 2 on the upper surface of the non-woven fabric 1 in step a;

[0031] c. Convey a bulky non-woven fabric 3 in a continuous manner, and spray glue on the upper surface of the bulky non-woven fabric 3, and then spray the polymer water-absorbing resin material 4 in the gap of the bulky non-woven fabric 3 Inside, the temperature of the spray gun used in the spraying of the polymer water-absorbent resin material 4 is controlled at 30°C, the air pressure is controlled at 0.5Mpa, and the depth of the ...

Embodiment 2

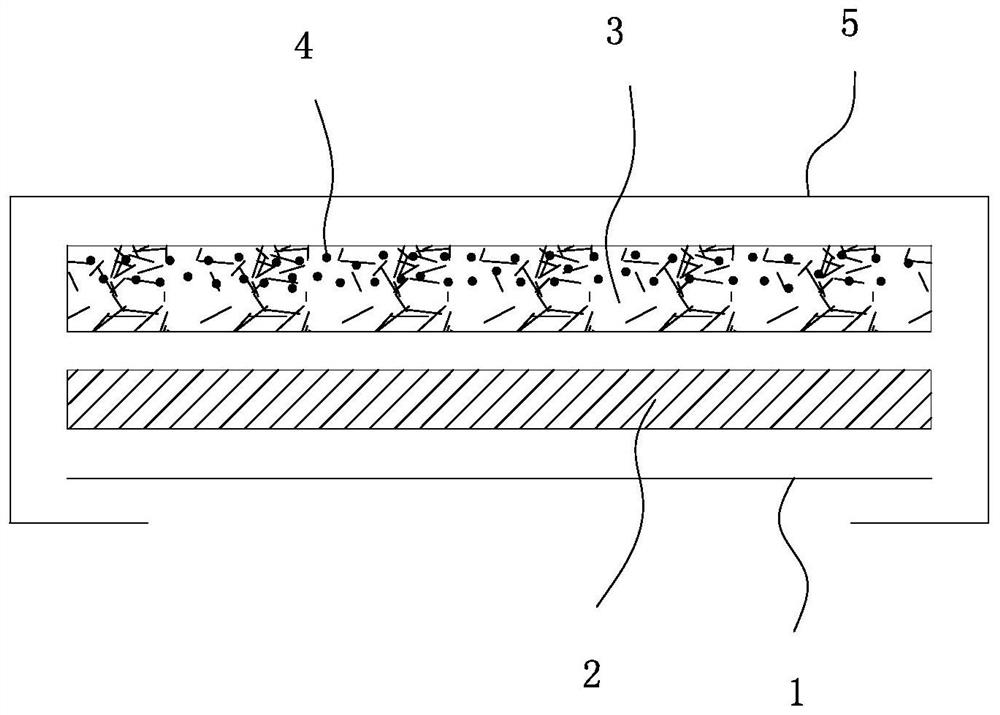

[0038] refer to Figure 5 , a preparation method of an improved composite core, comprising the following steps:

[0039] a. Convey a nonwoven fabric 1 in a continuous manner, define the conveying direction along the nonwoven fabric 1 as the longitudinal direction, and define the transverse direction along its width direction, and spray glue on the upper surface of the continuously conveyed nonwoven fabric 1 deal with;

[0040] b. Add polymer water-absorbing resin material 2 on the upper surface of the non-woven fabric 1 in step a;

[0041] c. Convey a bulky non-woven fabric 3 in a continuous manner, and press its lower surface with concave-convex rollers to form three parallel grooves 6 along the transverse direction, which are used in the spraying of the polymer water-absorbent resin material 4 The temperature of the spray gun is controlled at 30°C, the air pressure is controlled at 0.5Mpa, and the depth of the polymer water-absorbing resin material sprayed on the bulky non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com