A kind of polyurethane condom and preparation method thereof

A condom and polyurethane technology, applied in the direction of male contraceptives, coatings, etc., can solve the problems of difficult demoulding, difficult curling, and inconvenient wearing, and achieve the effect of ensuring ultra-thinness and overcoming difficult curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

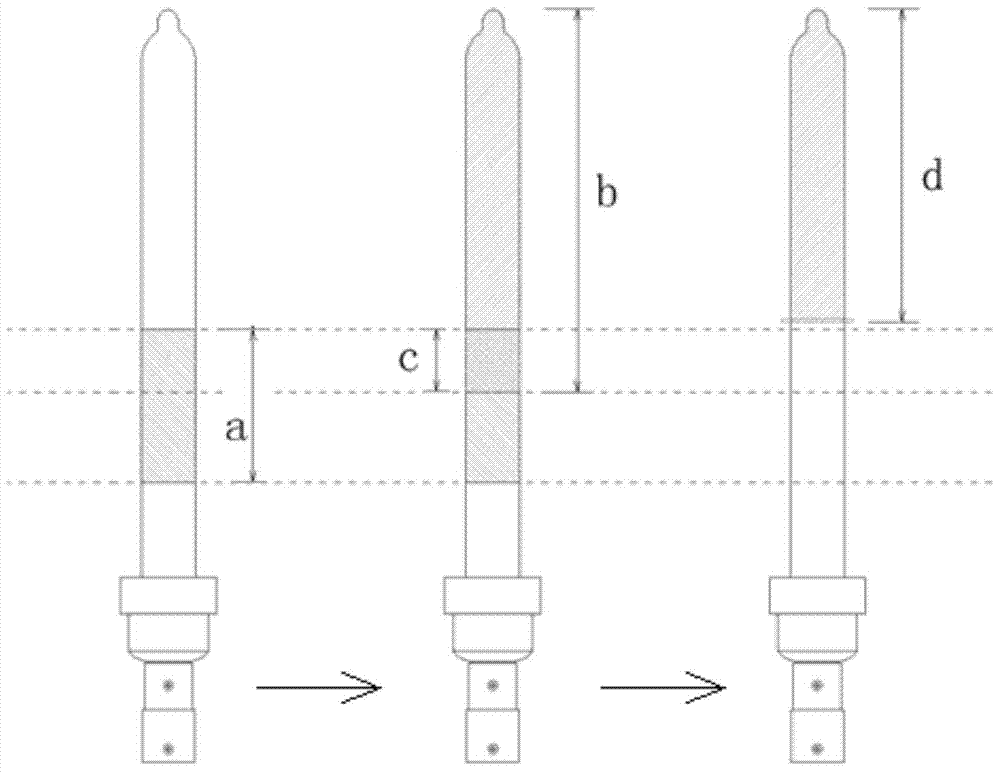

[0025] This embodiment relates to a polyurethane condom and its preparation method, which is composed of the following steps, wherein a district, b district, c district and d district are as follows figure 1 Shown:

[0026] Step 1, spray a layer of natural latex on the condom mold as zone a, bake at 70°C for 1 min, and the length of zone a is 60mm;

[0027] Step 2, dipping 3 layers of water-based polyurethane emulsion as zone b, each layer is baked at 110°C for 1 min, the b zone overlaps with the a zone, and this overlapping part is used as c zone;

[0028] Step 3, crimp the above-mentioned area a, roll it to or beyond area c, and use the remaining part as area d, then bake at 90°C for 20 minutes, the length of area d is 180mm, and the length of area b - the length of area d = 0mm;

[0029] Step 4, dipping a layer of release agent solid powder suspension on the outside of zone d, and baking at 80°C for 15 minutes;

[0030] Step 5: Cooling, demoulding, and post-processing to...

Embodiment 2

[0032] This embodiment relates to a polyurethane condom and its preparation method, which is composed of the following steps, wherein a district, b district, c district and d district are as follows figure 1 Shown:

[0033] Step 1: Apply a layer of polyisoprene as area a by brushing on the condom mold, bake at 80°C for 3 minutes, and the length of area a is 80mm;

[0034] Step 2, dipping a layer of water-based polyurethane emulsion as zone b, and baking at 70°C for 3 minutes, the zone b overlaps with zone a, and this overlapping part is used as zone c;

[0035] Step 3, crimp the above-mentioned zone a, roll it to or beyond zone c, and use the remaining part as zone d, then bake at 100°C for 30 minutes, the length of zone d is 155mm, and the length of zone b - the length of zone d = 2mm;

[0036] Step 4, dipping a layer of release agent solid powder suspension on the outside of zone d, and baking at 90°C for 20 minutes;

[0037] Step 5: Cooling, demoulding, and post-processi...

Embodiment 3

[0039] This embodiment relates to a polyurethane condom and its preparation method, which is composed of the following steps, wherein a district, b district, c district and d district are as follows figure 1 Shown:

[0040] Step 1: Apply a layer of natural latex on the condom mold by roller coating as zone a, bake at 90°C for 4 minutes, and the length of zone a is 100mm;

[0041] Step 2, dipping two layers of water-based polyurethane emulsion as zone b, and baking each layer at 80°C for 5 minutes, the b zone overlaps with the a zone, and this overlapping part is used as c zone;

[0042] Step 3, crimp the above-mentioned area a, roll it to or beyond area c, and use the remaining part as area d, then bake at 110°C for 1 min, the length of area d is 160mm, and the length of area b - the length of area d = 5mm;

[0043] Step 4, impregnating a layer of release agent solid powder suspension on the outside of zone d, and baking at 100°C for 30 minutes;

[0044] Step 5: Cooling, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com