Preparation method and application of strong-adsorption-type ultrafiltration membrane

An ultrafiltration membrane and strong adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, membranes, etc., can solve the problems of increasing raw material input costs, increasing filtration steps, time-consuming and labor-intensive, etc., and achieve good anti-pollution ability , prevent aggregation, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

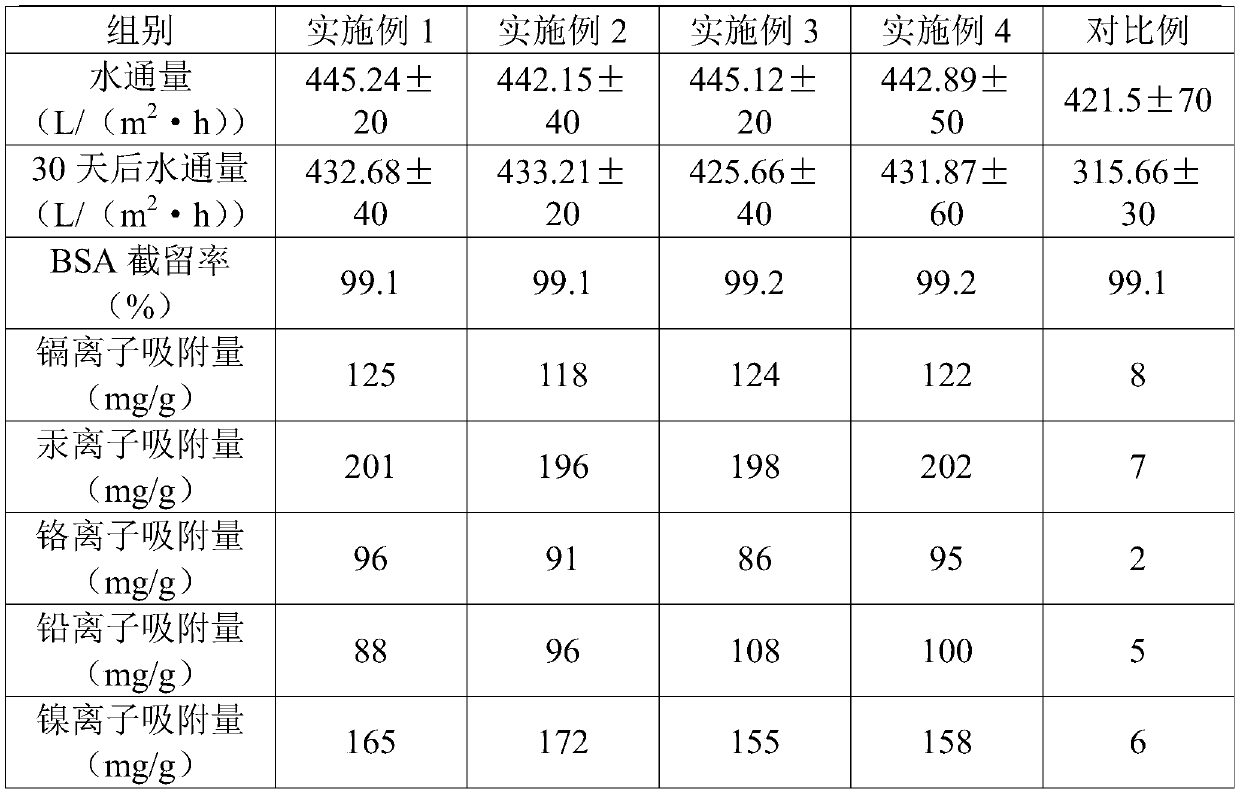

Examples

Embodiment 1

[0027] Add 5g of polysulfone to 80g of N-methylpyrrolidone, mix and stir for 10min at normal temperature, the polysulfone is completely dissolved, and the ultrafiltration membrane liquid of polysulfone is obtained. The thickness of the membrane is 200 μm, and it is dried under normal temperature and pressure for 10 minutes to obtain an ultrafiltration membrane;

[0028] Put 10g of fibrous polyimide into 80g of N,N-dimethylacetamide, mix and stir for 10min at room temperature, the fibrous polyimide is completely dissolved, and obtain N,N-dimethylacetamide of polyimide The casting solution of polyimide was defoamed for 30 minutes under vacuum, and the casting solution of polyimide was scraped by a flat film scraping machine. The thickness of the scraping film was 50 μm, and it was dried at room temperature for 10 minutes to obtain an adsorption film;

[0029] Use an electron beam with an energy of 0.5 MeV to irradiate the ultrafiltration membrane and the adsorption membrane vert...

Embodiment 2

[0032] Add 20g of polyethersulfone to 60g of N,N-dimethylformamide, mix and stir for 5min at room temperature, the polyethersulfone is completely dissolved, and the ultrafiltration membrane liquid of polyethersulfone is obtained. The filtrate is subjected to scraping treatment, the thickness of the scraped membrane is 400 μm, and it is dried at normal temperature and pressure for 5 minutes to obtain an ultrafiltration membrane;

[0033] Put 10g of fibrous polyimide into 120g of N,N-dimethylacetamide, mix and stir for 5min at room temperature, the fibrous polyimide is completely dissolved, and obtain N,N-dimethylacetamide of polyimide The casting solution of polyimide was defoamed for 60 minutes under vacuum, and the casting solution of polyimide was scraped by a flat film scraping machine. The thickness of the scraping film was 100 μm, and it was dried at room temperature for 5 minutes to obtain an adsorption film;

[0034] The ultrafiltration membrane and the adsorption membr...

Embodiment 3

[0037] Add 10g of polyvinylidene fluoride to 70g of N,N-dimethylacetamide, mix and stir for 10min at room temperature, the polyvinylidene fluoride is completely dissolved, and obtain the ultrafiltration membrane liquid of polyvinylidene fluoride, and use a flat scraper to remove the polyvinylidene fluoride The vinylidene fluoride ultrafiltration membrane solution is subjected to scraping treatment, the thickness of the scraped membrane is 300 μm, and it is dried at normal temperature and pressure for 10 minutes to obtain an ultrafiltration membrane;

[0038] Put 10g of fibrous polyimide into 100g of N,N-dimethylacetamide, mix and stir for 10min at room temperature, the fibrous polyimide is completely dissolved, and obtain N,N-dimethylacetamide of polyimide The casting solution of polyimide was defoamed for 40 minutes under vacuum, and the casting solution of polyimide was scraped by a flat film scraping machine. The thickness of the scraping film was 80 μm, and it was dried at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com