A kind of porous nano-cobalt-doped zinc manganate spinel catalyst and its preparation method and application

A technology of cobalt zinc manganate and spinel, which is applied in the field of porous nano-cobalt-doped zinc manganate spinel catalyst and its preparation, can solve the problems of strong toxicity and limit the application of Co materials, and achieves large specific surface area and good physical properties. The effect of chemical stability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1.2.5mmol zinc acetate, 2.5mmol manganese acetate and 2.5mmol cobalt acetate and 12mmol citric acid were dissolved in 30ml deionized water and 2.5ml nitric acid to obtain a mixed solution;

[0036] 2. The mixed solution was continuously stirred and heated to 90°C for 8 hours to obtain a viscous gel;

[0037] 3. The gel was placed in an oven at 170°C for 8 hours to remove remaining water, the dried gel was thoroughly ground and annealed in air at 550°C for 7 hours (heating rate: 10°C min. -1 ) to obtain ZnCoMnO 4 Spinel powder.

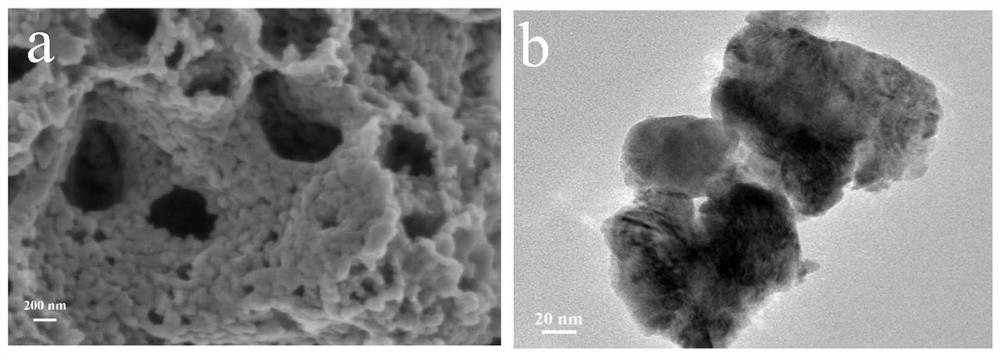

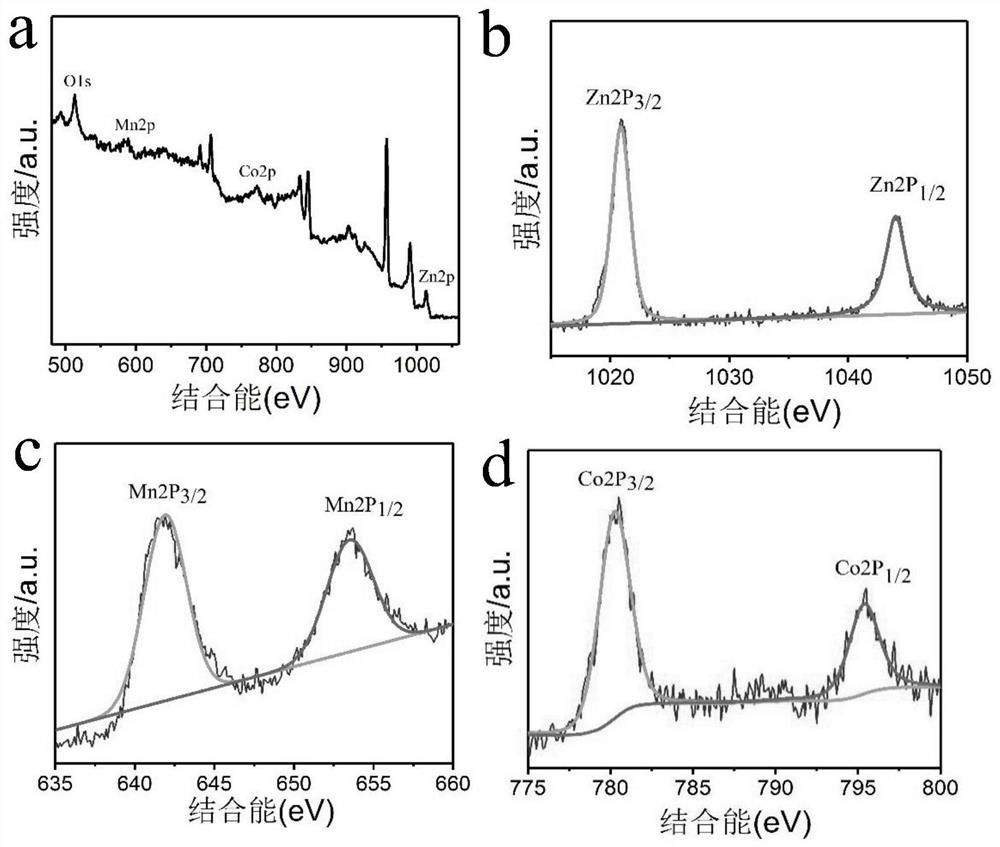

[0038] figure 1 ZnCoMnO in this example 4 SEM and TEM pictures of the spinel material. Depend on figure 1 It can be seen that ZnCoMnO 4 The surface of the spinel material exhibits a porous structure, which is agglomerated by nanoparticles of 50-100 nm. The porous structure may be due to the combustion of citric acid as a raw material during the annealing stage to generate a large amount of CO 2 , pores are formed when the gas is released...

Embodiment 2

[0040] 1.2.5mmol zinc acetate, 4.5mmol manganese acetate and 0.5mmol cobalt acetate and 16mmol citric acid were dissolved in 30ml deionized water and 1.5ml nitric acid to obtain a mixed solution;

[0041] 4. The mixed solution was continuously stirred and heated to 90°C for 8 hours to obtain a viscous gel;

[0042] 5. The gel was placed in an oven at 170°C for 16 hours to remove remaining water, the dried gel was thoroughly ground and annealed in air at 650°C for 5 hours (heating rate: 10°C min -1 ) to obtain ZnCoMnO 4 Spinel powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com