Board locating and carrying device

A handling device and sheet material technology, applied in the field of non-contact smart card manufacturing equipment, can solve the problems of lower product yield, lower coil winding accuracy, composite welding processing accuracy, repeated lamination accuracy, and easy damage, and achieve precise positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

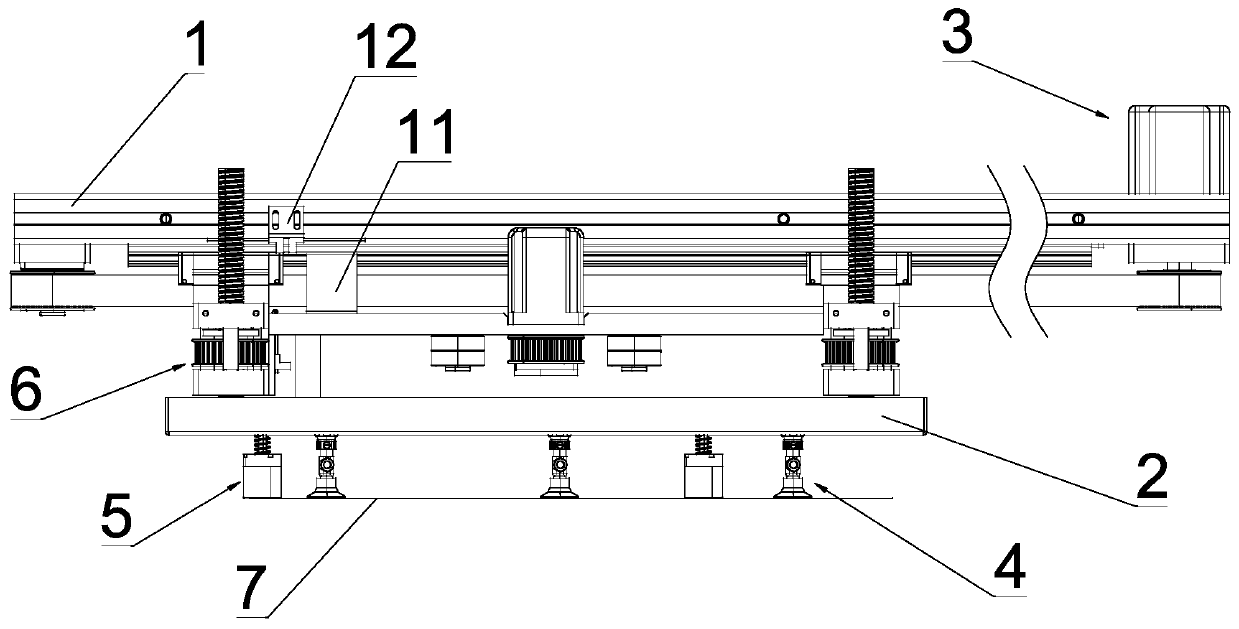

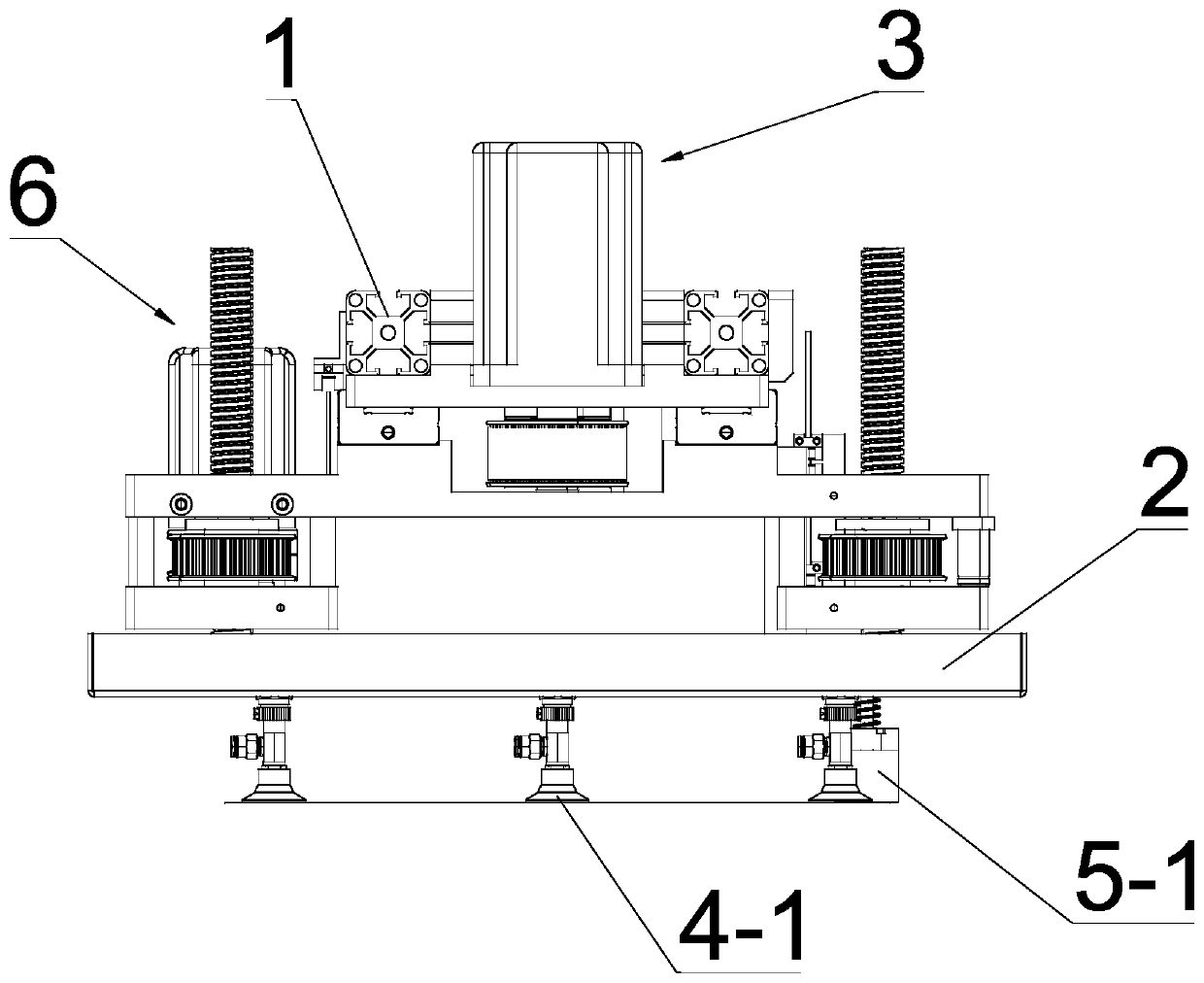

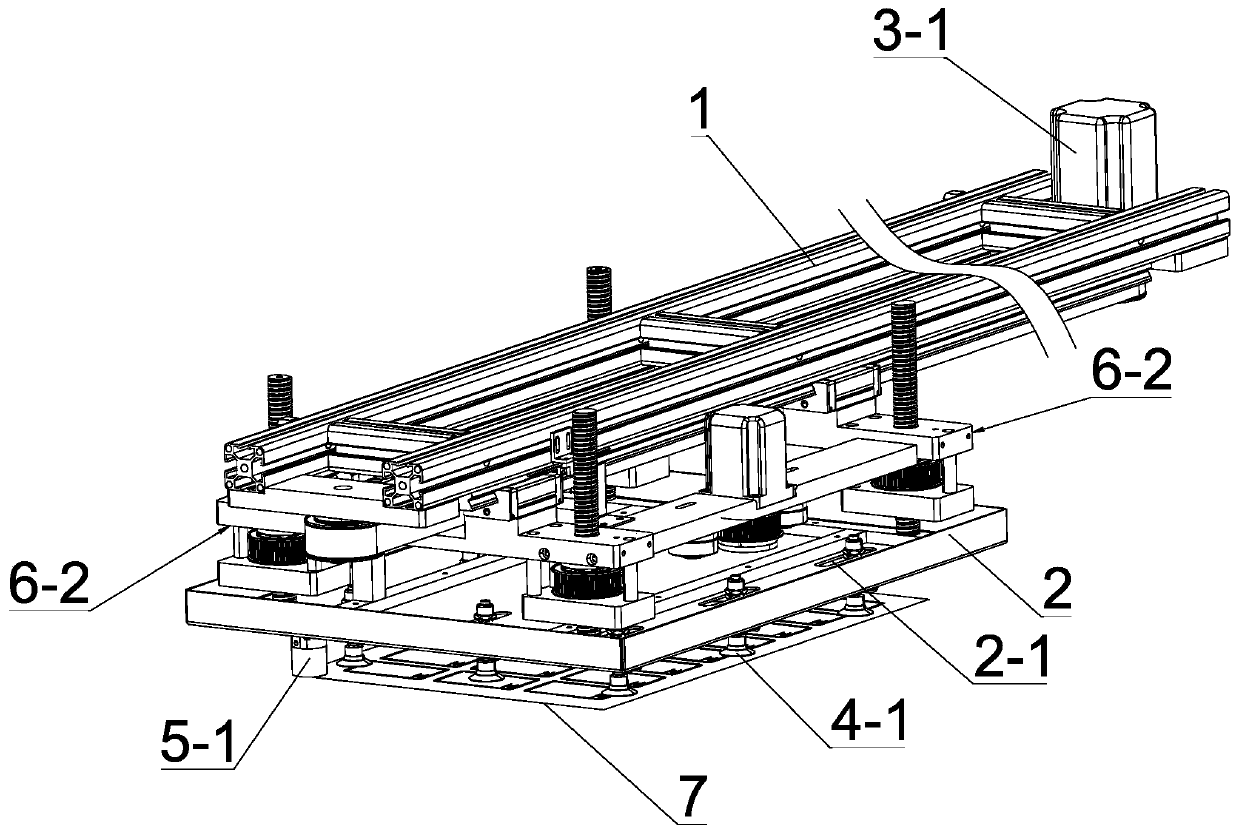

[0042] see Figure 1-Figure 6 , the sheet material positioning and conveying device of the present invention includes a frame 1, a sheet material conveying mechanism arranged on the frame 1, and drives the sheet material conveying mechanism between the pre-carrying station and the post-carrying station of the sheet material 7 A reciprocating lateral drive mechanism 3; wherein, the plate handling mechanism includes a mounting frame 2, a suction cup assembly 4 arranged on the mounting frame 2, at least two sets of positioning assemblies 5, and drives the suction cup assembly 4 and the positioning assembly 5 vertical power mechanism 6 for vertical movement; the suction cup assembly 4 includes a plurality of suction cups 4-1 for holding the sheet material 7, and the positioning assembly 5 includes a positioning hole 7-1 for the sheet material 7 Positioning part 5-1 for positioning at 1 position; the positioning part 5-1 is provided with an avoidance groove 5-11 for avoiding the po...

Embodiment 2

[0062] see Figure 12 , in this embodiment, different from Embodiment 1, the vertical drive assembly of the positioning assembly 5 can also be in another form, the vertical drive assembly includes a slide rail mechanism and the spring 5- 4; wherein the slider slide rail mechanism includes a positioning guide rail 5-5 and a positioning slider 5-6 matched with the positioning guide rail 5-5; the upper end of the guide rail and the mounting frame 2 connection, the positioning piece 5-1 is fixed on the lower end of the positioning slider 5-6 through the connecting piece 5-7, and the lower part of the positioning guide rail 5-5 is also provided for limiting the positioning slider 5 - the limiting part 5-21 at position 6, the spring 5-4 is arranged between the installation frame 2 and the positioning slider 5-6, one end of the spring 5-4 acts on the frame 1, One end acts on the positioning slider 5-6. Through the slide rail mechanism, the stability of the positioning member 5-1 du...

Embodiment 3

[0064] see Figure 13 , the difference from Embodiments 1 and 2 is that the vertical power mechanism 6 can be in another form, the screw drive assembly is a group, and the first driven drive wheel 6-6 is arranged on the On the vertical fixing seat 6-2, a guide post guide sleeve mechanism for guiding the installation frame 2 to move up and down is provided between the installation frame 2 and the vertical fix seat 6-2, wherein the guide post guide sleeve mechanism is Multiple groups, the multiple sets of guide post and guide sleeve mechanisms are distributed around the mounting frame 2; each set of guide post and guide sleeve mechanisms includes guide posts 6-9 and guide sleeves 6-9 that cooperate with the guide posts 6-9 10. One end of the guide sleeve 6-10 is fixed on the vertical fixing base 6-2, one end of the guide post 6-9 is fixed on the installation frame 2, and the other end extends vertically upwards and passes through the guide Set 6-10; the screw rod 6-3 of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com