Track transmission mechanism for continuously pressurized belt-type dehydrator and application of track transmission mechanism

A crawler drive and belt dehydration technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of high energy consumption of power source, poor running stability and heavy weight of filter press crawler, etc. problems, to achieve the effect of ensuring accuracy and stability, reducing equipment maintenance costs, and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

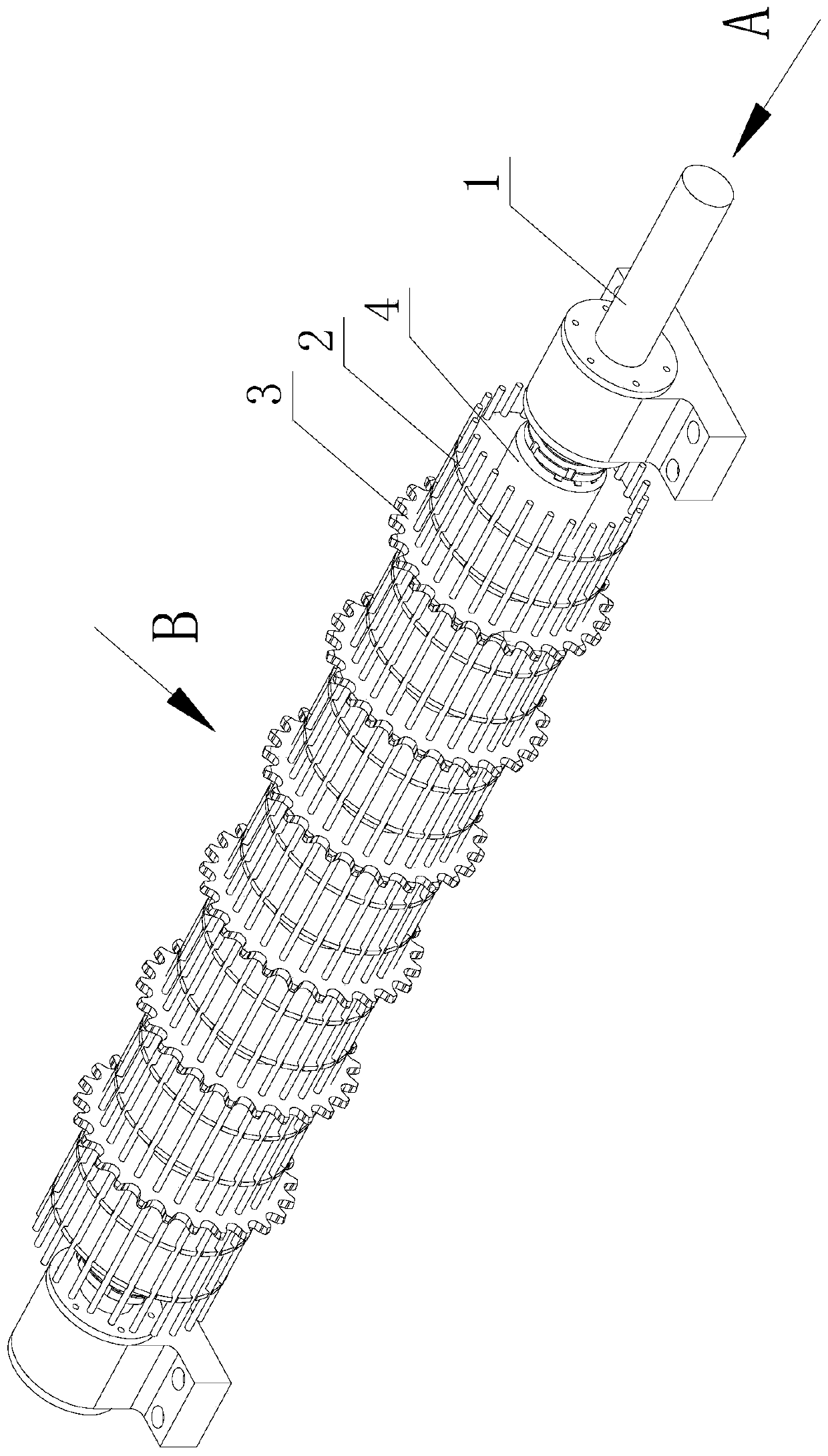

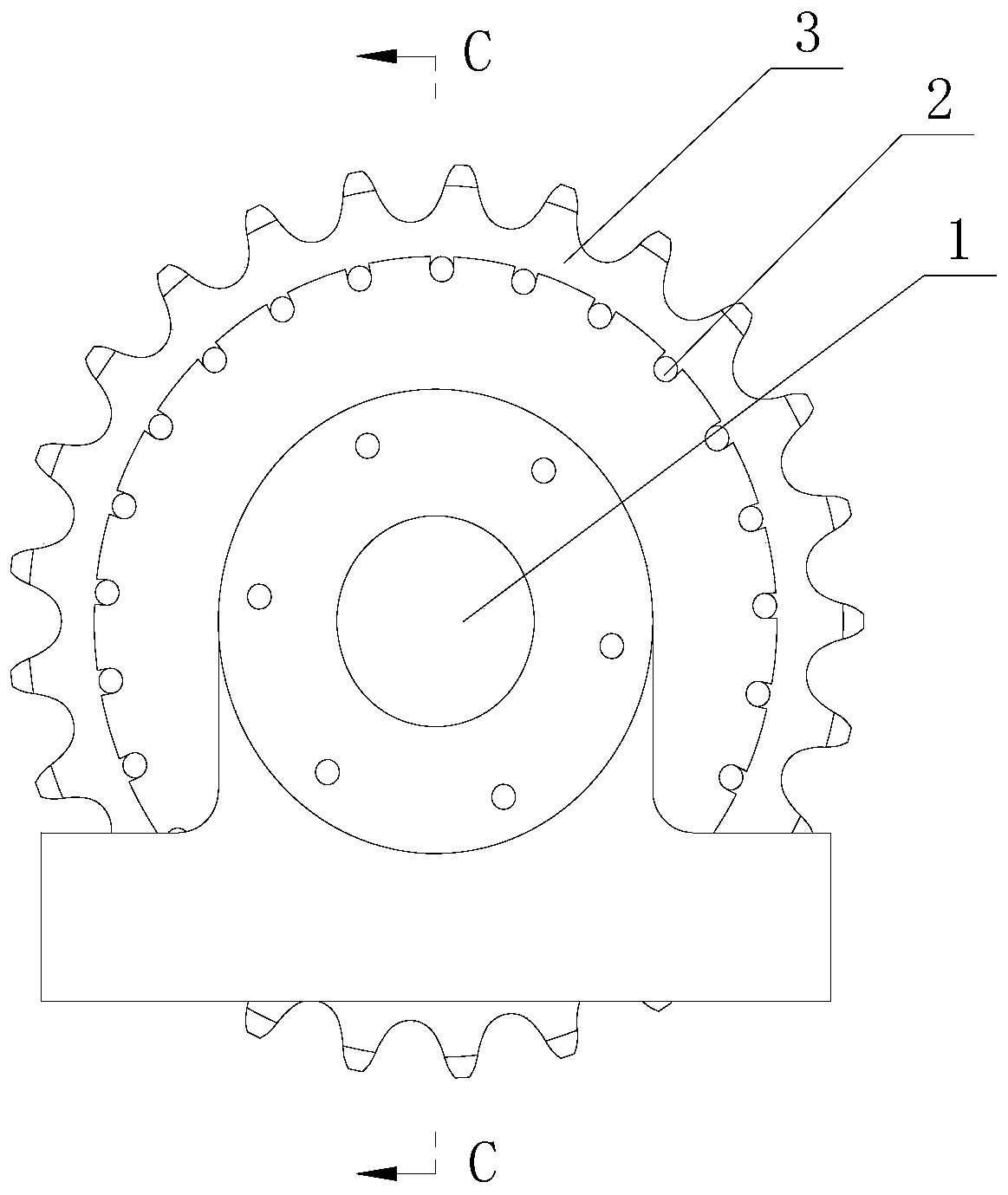

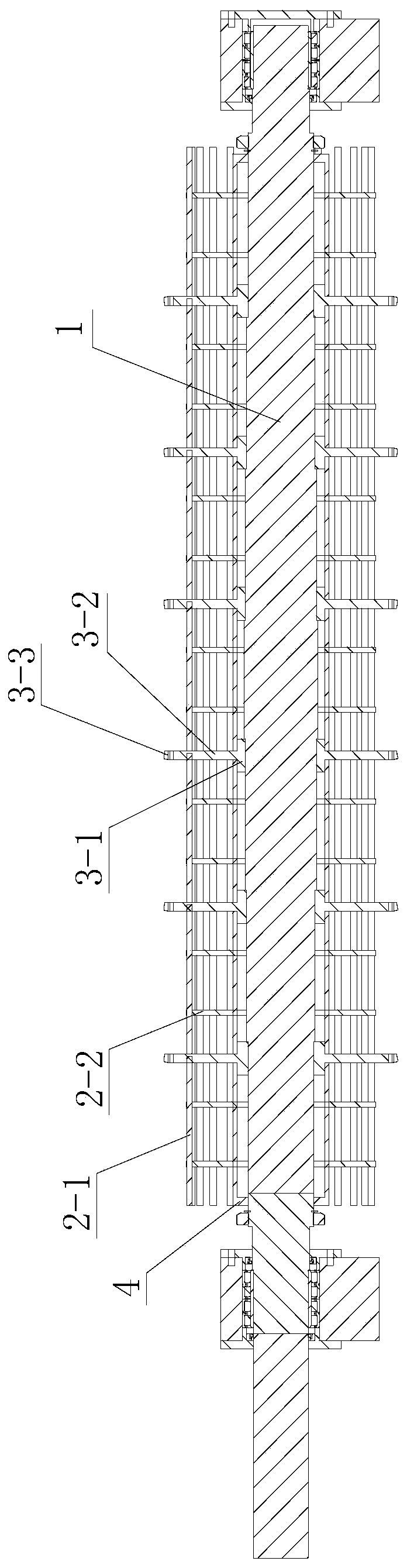

[0031] A kind of crawler belt drive mechanism that the present embodiment is used for continuous pressurized belt dehydrator, such as Figure 1 to Figure 4 As shown, it includes a rotating shaft 1, a supporting part 2 and a sprocket 3. Along the axial direction of the rotating shaft, a supporting part is arranged on the outer periphery of the rotating shaft, and a plurality of sprockets are distributed on the rotating shaft, and the outer diameter of each sprocket is larger than that of the supporting part. The outer diameter of each sprocket is in contact with the filter press track, and the outer surface of the support part is in contact with the surface of the filter press track. In this structure, the rotating shaft is externally connected with driving motors, couplings and other power components, and drives the filter press crawler to run by driving the rotation of the sprocket. During the operation of the filter press crawler, the support part plays a load-bearing role on...

Embodiment 2

[0040] This embodiment is a crawler belt transmission mechanism for a continuous pressurized belt dehydrator. Compared with Embodiment 1, the difference is that the support part is in the shape of a roller as a whole, and the two ends or / and the inner side of the support part are connected to the installation The sleeves are connected by bearings. The support part of this structure has a better load-bearing effect and can better ensure the stability of equipment operation, but its weight will be larger than that of the cage structure of the same specification, which will increase the equipment cost.

Embodiment 3

[0042] This embodiment is a crawler belt transmission mechanism for a continuous pressurized belt dehydrator. Compared with Embodiment 1, the difference is that the support part includes a plurality of support units connected in the axial direction, and two adjacent support units A sprocket is set between them, and the support unit is used for splicing. The number of support units can be flexibly selected according to the actual width of the filter press crawler, which is convenient for use and installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com