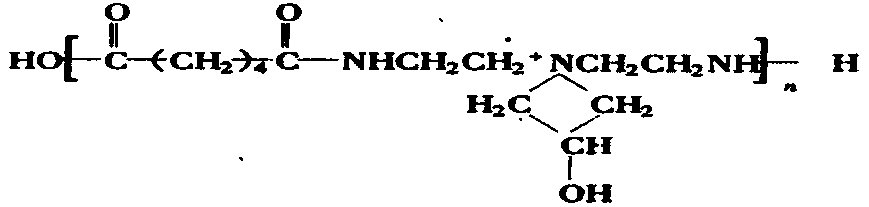

Method for deacidifying and enhancing acidified and aged paper documents by sodium silicate or borax and polyamide epichlorohydrin complex

A technology of epichlorohydrin and sodium silicate, applied in chemical/biochemical treatment of paper, papermaking, paper coating, etc., can solve problems such as low pH value, increased paper strength performance, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve or dilute borax and PAE separately using deionized water to a concentration of 2 wt % solution (magnetic stirring 5 ~ 30min), according to the borax and PAE effective component mass ratio is 2:1 preparation composite solution, and it is placed in the watering can, evenly sprayed on acidified and aged paper documents (paper pH is 4.73 , whiteness is 39.5%, tensile index is 16.92N·m / g) surface, dosage is 2.5g / m 2 . After treatment, the treated paper is naturally aired at room temperature until the surface has no obvious wet state, then placed in an oven, heated at 50°C for 20 minutes, compared with untreated paper, the pH of the paper is 7.45, and the tensile index is 19.95N m / g (increased by 17.9%), there is no change in the text and graphics on the surface of the book, and the whiteness of the paper is slightly improved.

Embodiment 2

[0034] Dissolve or dilute borax and PAE separately using deionized water to a concentration of 2 wt% solution (magnetic stirring 5 ~ 30min), according to the borax and PAE effective component mass ratio is 3:2 preparation composite solution, and it is placed in the watering can, evenly sprayed on acidified and aged paper documents (paper pH is 4.73 , whiteness is 39.5%, tensile index is 16.92N·m / g) surface, dosage is 3.0g / m 2 . After treatment, the treated paper is naturally aired at room temperature until the surface has no obvious wet state, then placed in an oven, heated at 60°C for 20 minutes, compared with untreated paper, the pH of the paper is 7.02, and the tensile index is 20.78N ·m / g (increased by 28.7%), the text on the surface of the book does not change, and the whiteness of the paper is slightly improved.

Embodiment 3

[0036] Dissolve or dilute borax and PAE separately using deionized water to a concentration of 2 wt % solution (magnetic stirring 5~30min), according to the mass ratio of borax and PAE effective component is 1:1 preparation composite solution, and it is placed in the watering can, evenly sprayed on the acidified and aged paper document (paper pH is 4.73 , whiteness is 39.5%, tensile index is 16.92N·m / g) surface, dosage is 4.0g / m 2 . After treatment, the treated paper is naturally aired at room temperature until the surface has no obvious wet state, then placed in an oven, and heated at 60°C for 30 minutes. Compared with untreated paper, the pH of the paper is 7.10, and the tensile index is 23.47N m / g (increased by 38.7%), the text on the surface of the book has no change, and the whiteness of the paper has basically remained the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile index | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com