Overmolded lead frame assembly for pressure sensing applications

一种引线框架、成型引线的技术,应用在测量流体压力、多个阀之间的压力差测量、测量力等方向,能够解决没有保护性特征、限制产品使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

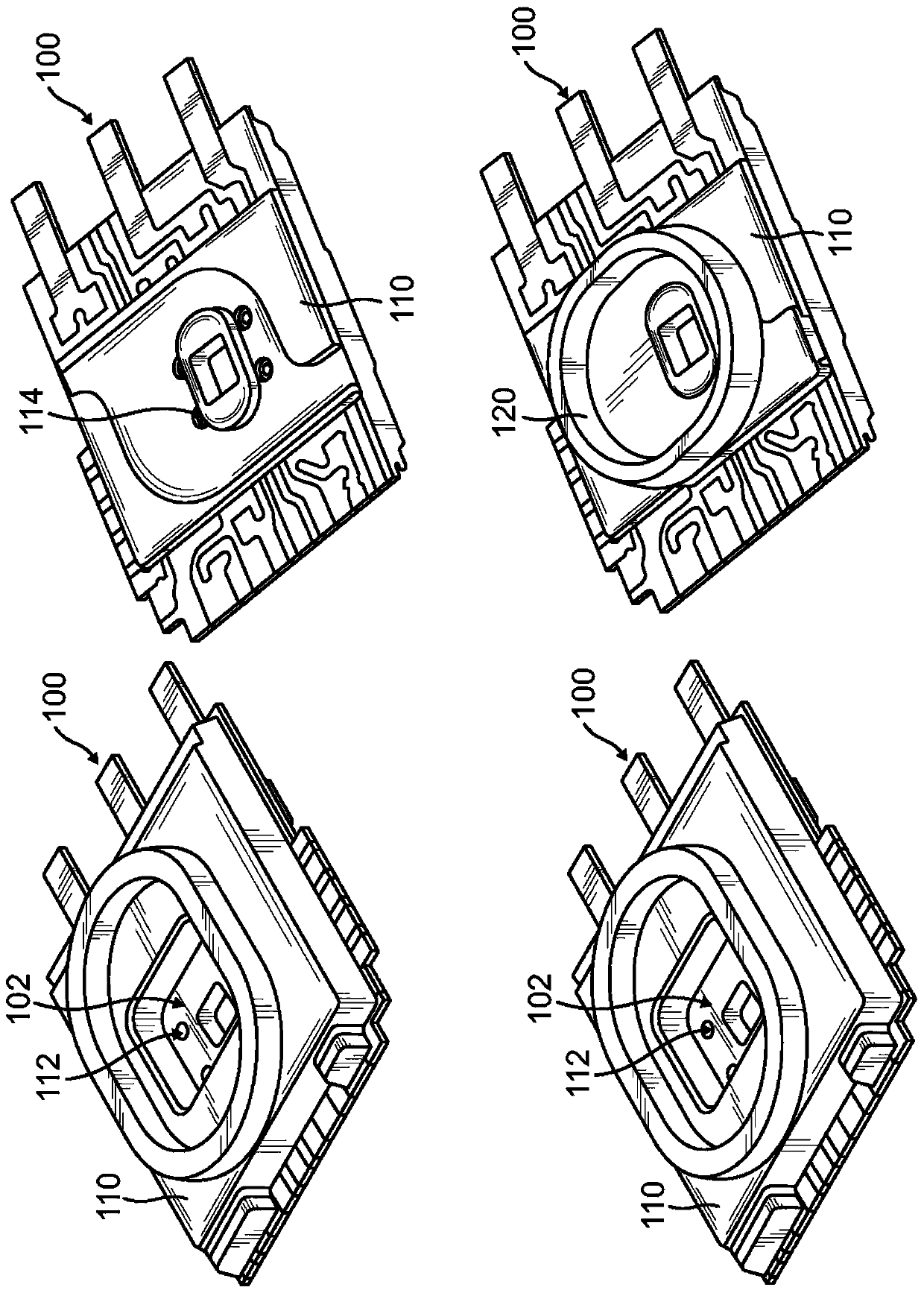

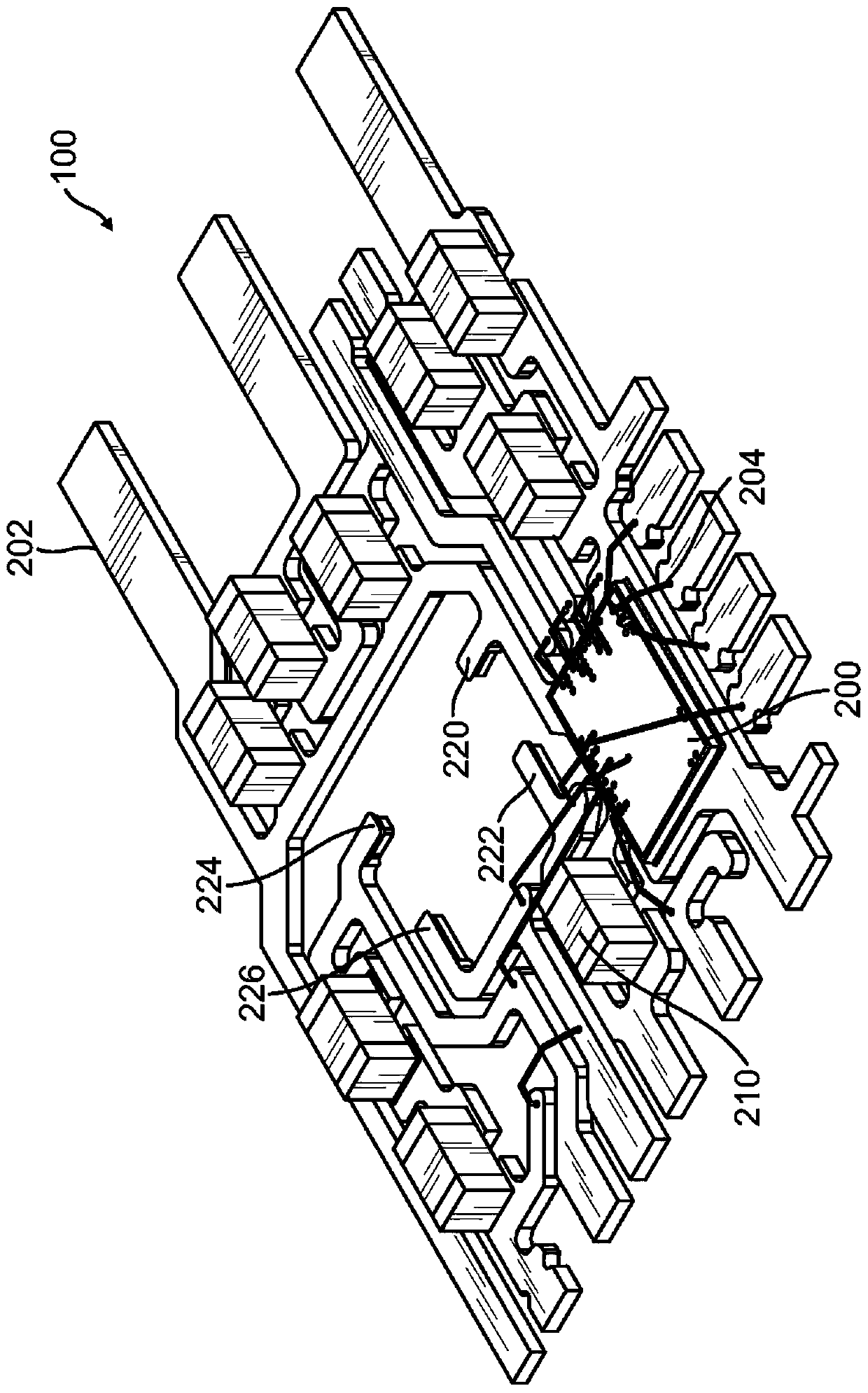

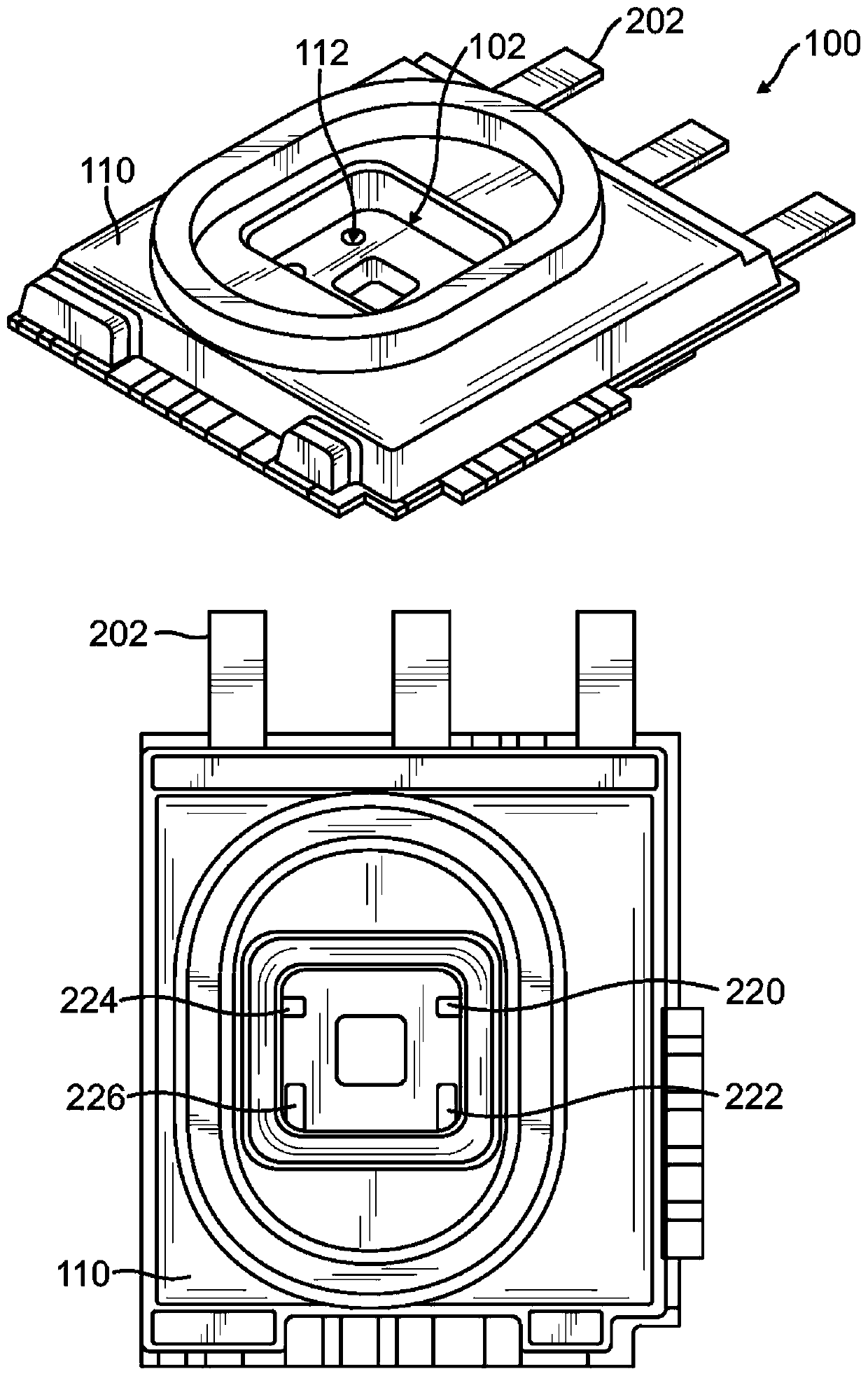

[0019] The present disclosure describes a process of forming an overmolded leadframe assembly for pressure sensing applications and a pressure sensing package including the overmolded leadframe assembly. A pressure sensing package according to the present disclosure has a thermoset epoxy overmolded construction of a lead frame assembly. In some embodiments, the lead frame assembly has an ASIC (eg, an ASIC with signal conditioning circuitry) attached to the lead frame. The process of the present disclosure addresses the problem of the thermoset epoxy's tendency to resin flash over the lead frame during the molding process, including wire bond pads that should be cleaned to prevent wire bond lift.

[0020] During the molding process, double-sided clamping of the lead frame protects the wire bond pads on the first side of the lead frame (also referred to herein as the "top side") from resin flash, but can cause Unnecessary exposure of the second side (also referred to herein as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com