Design method of motor parameters based on global optimal annual consumption of water pump load

A technology of motor parameters and design methods, applied in design optimization/simulation, geometric CAD, etc., can solve problems such as increased power consumption, failure to achieve high efficiency and energy saving, and decreased pump motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

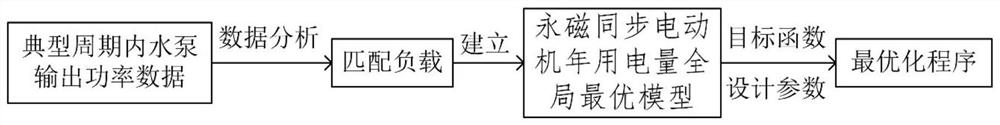

[0079] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the load model in which the output power matches the load of the water plant pump in the embodiment of the present invention. The present invention first collects the output power data of the target water plant pump motor, and then first collects the water pump output power data collected from the water plant Process and filter out the maximum value P max and minimum P min , the range of the data interval is shown in the following formula (1):

[0080] D=[P min P max ] (1)

[0081] Divide this data range into 4 partitions, and divide the four typical partitions so that similar data can be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com