Steel production equipment hidden danger level automatic identification alarm system

A technology of production equipment and alarm system, applied in the field of automatic identification and alarm system of hidden danger level of steel production equipment, can solve the problems of difficult control of maintenance risk, downtime affecting output, high maintenance cost, novel structure, easy popularization and application, and improved reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

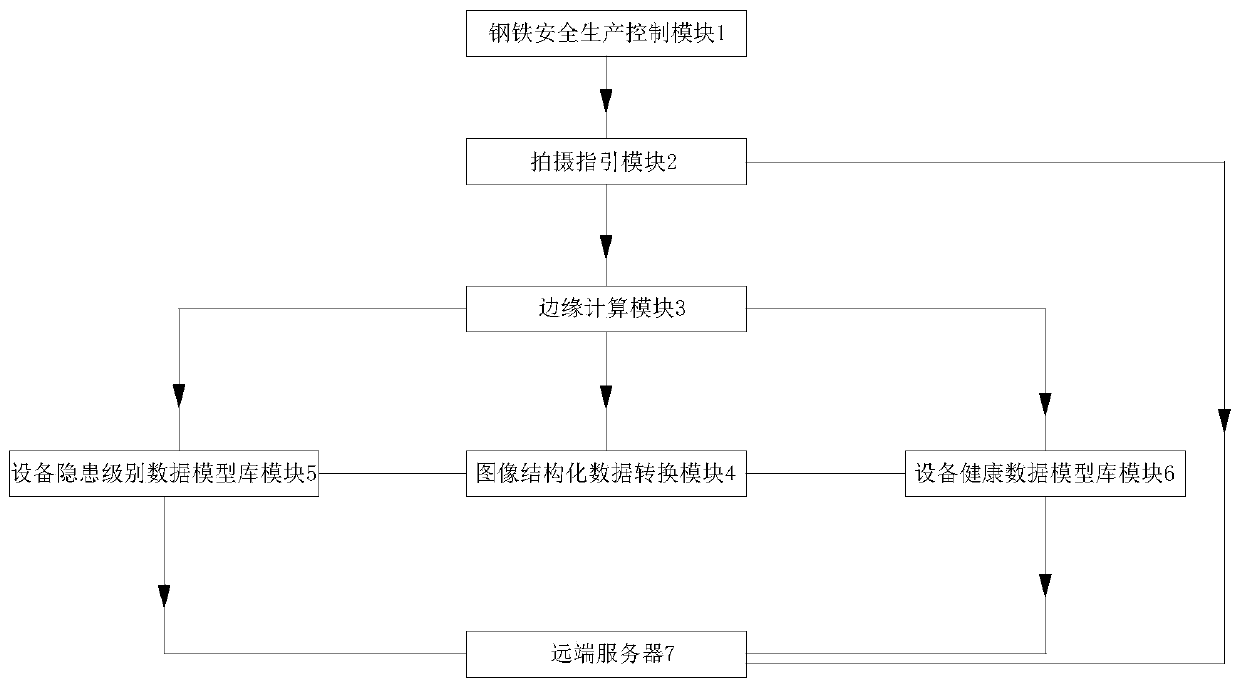

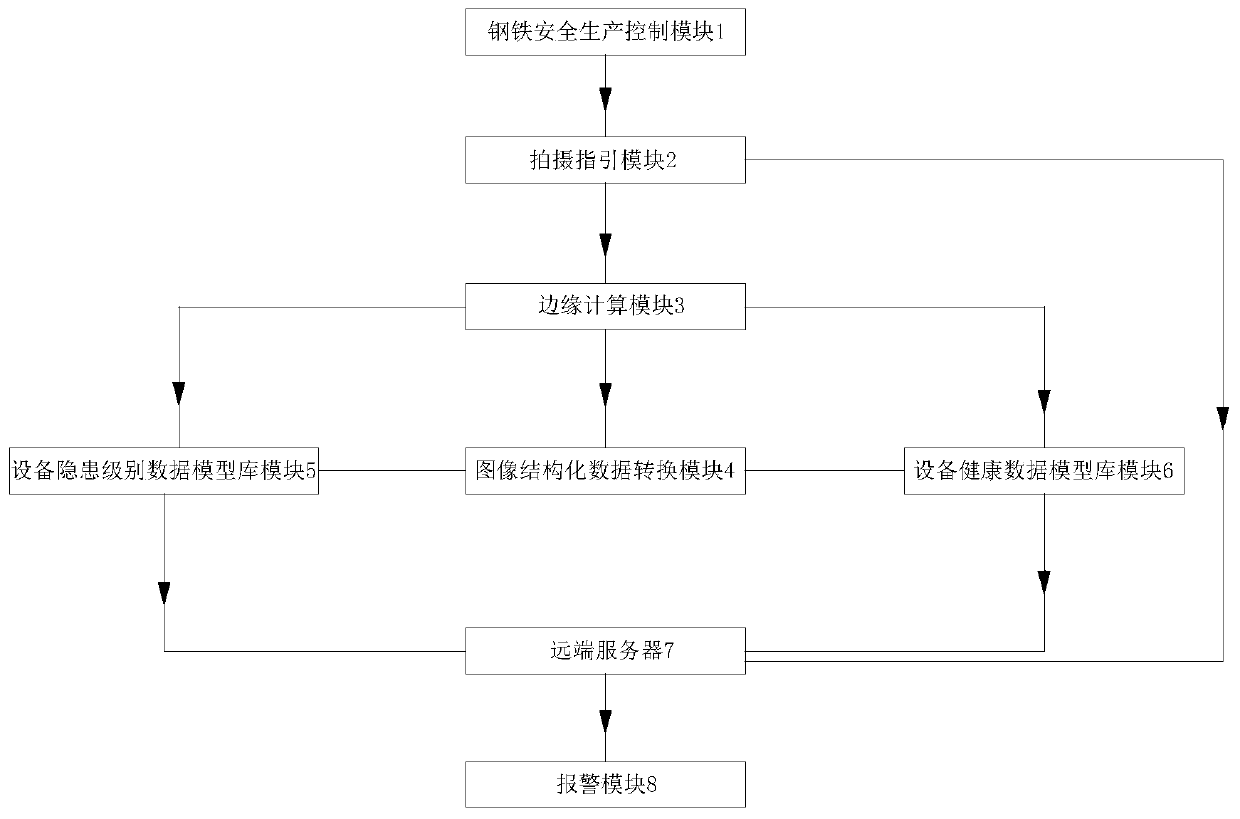

[0037] like figure 1 As shown, the automatic identification and alarm system for hidden danger levels of iron and steel production equipment includes steel safety production control module 1, shooting guidance module 2, edge computing module 3, image structured data conversion module 4, equipment hidden danger level data model library module 5, and equipment health Data model library module 6, remote server 7;

[0038] Iron and steel safety production control module 1 is connected with shooting guidance module 2, and is used to control the work of shooting guidance module 2;

[0039]The shooting guide module 2 is used to store the types of inspection equipment for steel production and their corresponding shooting positions and angles, and to guide the inspection equipment for iron and steel production according to the types of inspection equipment for steel production and their corresponding shooting positions and angles. to shoot;

[0040] The edge computing module 3 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com