Cavity plate non-magnetic material filling eddy current blocking process of explosion-proof electric appliance

An eddy current, non-magnetic technology, applied in the direction of circuits, electric switches, electrical components, etc., to achieve the effect of increasing the rated operating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

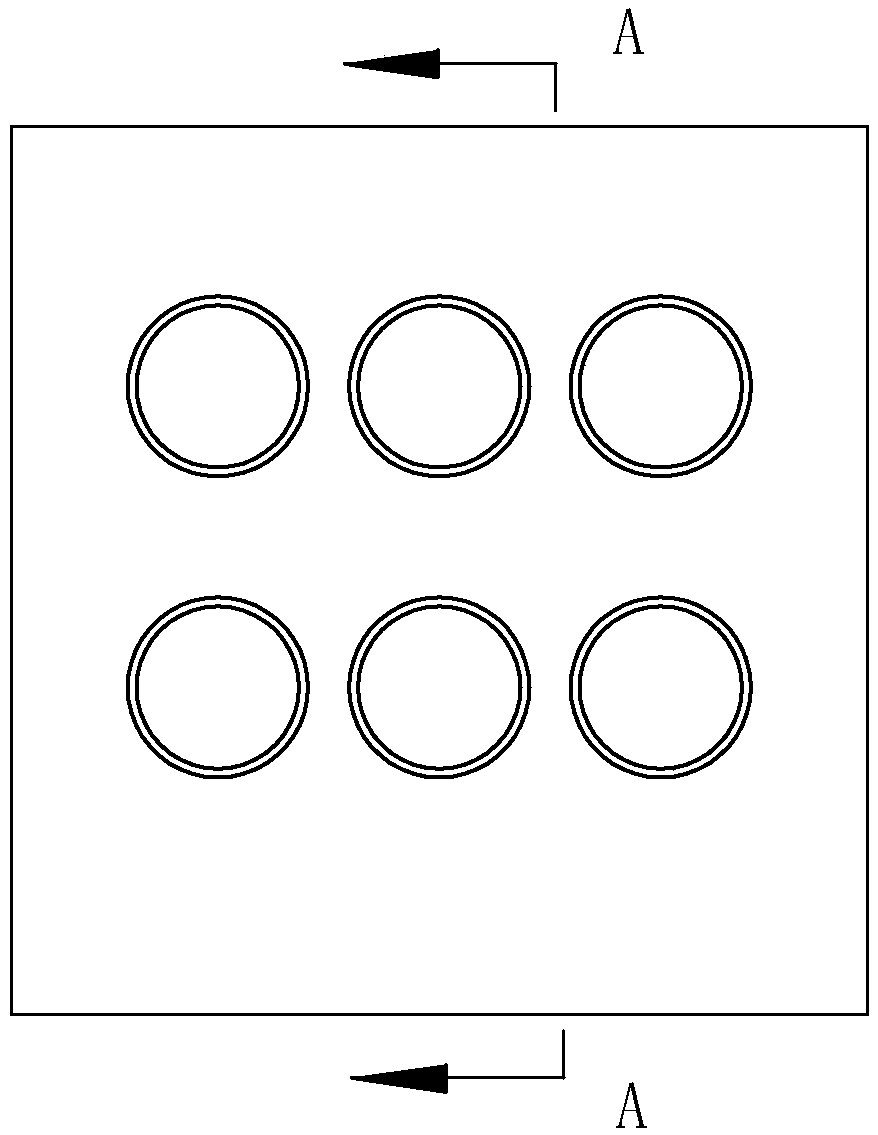

[0030] Flameproof electrical products are equipped with several space cavities according to different functions. Each functional cavity is completely separated and must meet the relevant performance requirements of flameproof structures. These requirements are mainly between the cavities. It can withstand the water pressure test of 1MP water pressure for 12s without leakage or deformation. It must finally pass the explosion test. When the mixed explosive gas is ignited in the main cavity, it cannot detonate another cavity or detonate the external explosive gas. This is also a mandatory test requirement that flameproof products must meet.

[0031] The following is attached Figure 2-9 The illustrations and examples illustrate the invention in detail.

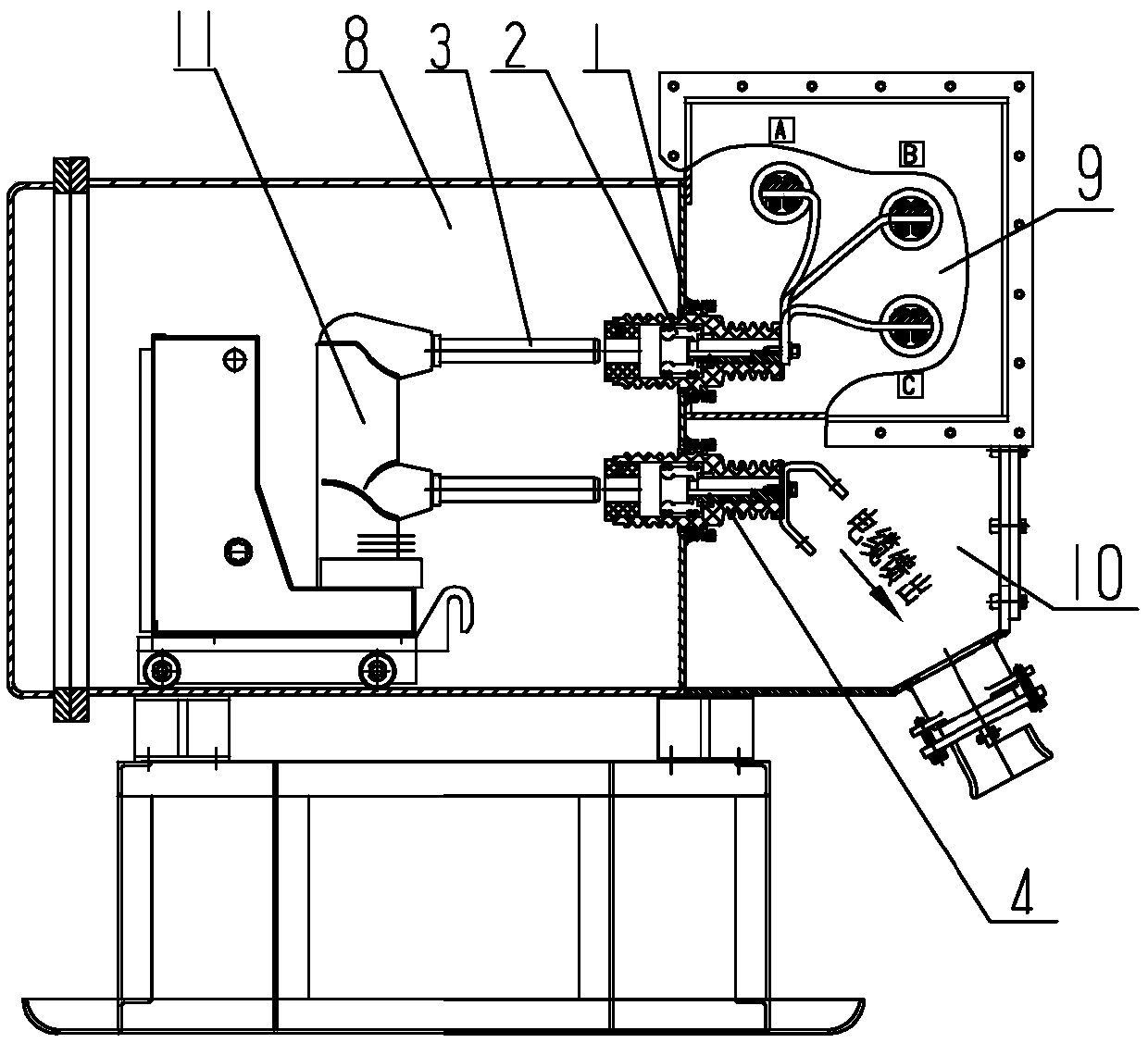

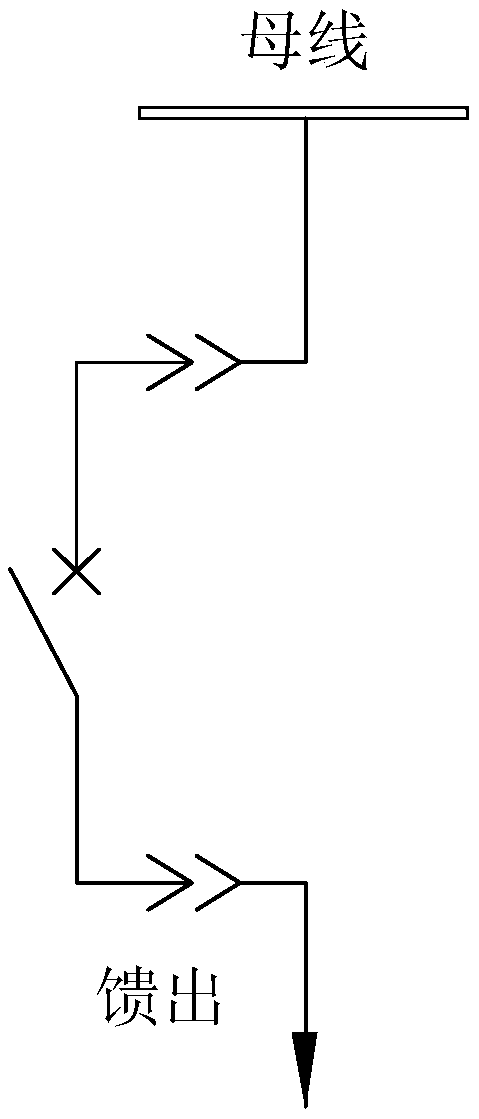

[0032] In this example, if figure 2 In the explosion-proof high-voltage vacuum switch cabinet shown, the cabinet body is divided into a switch cavity 8 (main cavity), a bus connection cavity 9, and a feed-out connection cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com