Continuation device and method of optical fiber composite low-voltage cable

A low-voltage cable and optical fiber composite technology, which is applied in the connection/termination of cable equipment, optical waveguide coupling, optics, etc., can solve problems such as construction difficulties, construction quality guarantees, and optical fiber damage, and facilitate transportation and inspection. , Eliminate defects and hidden dangers, and promote the effect of infrastructure construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

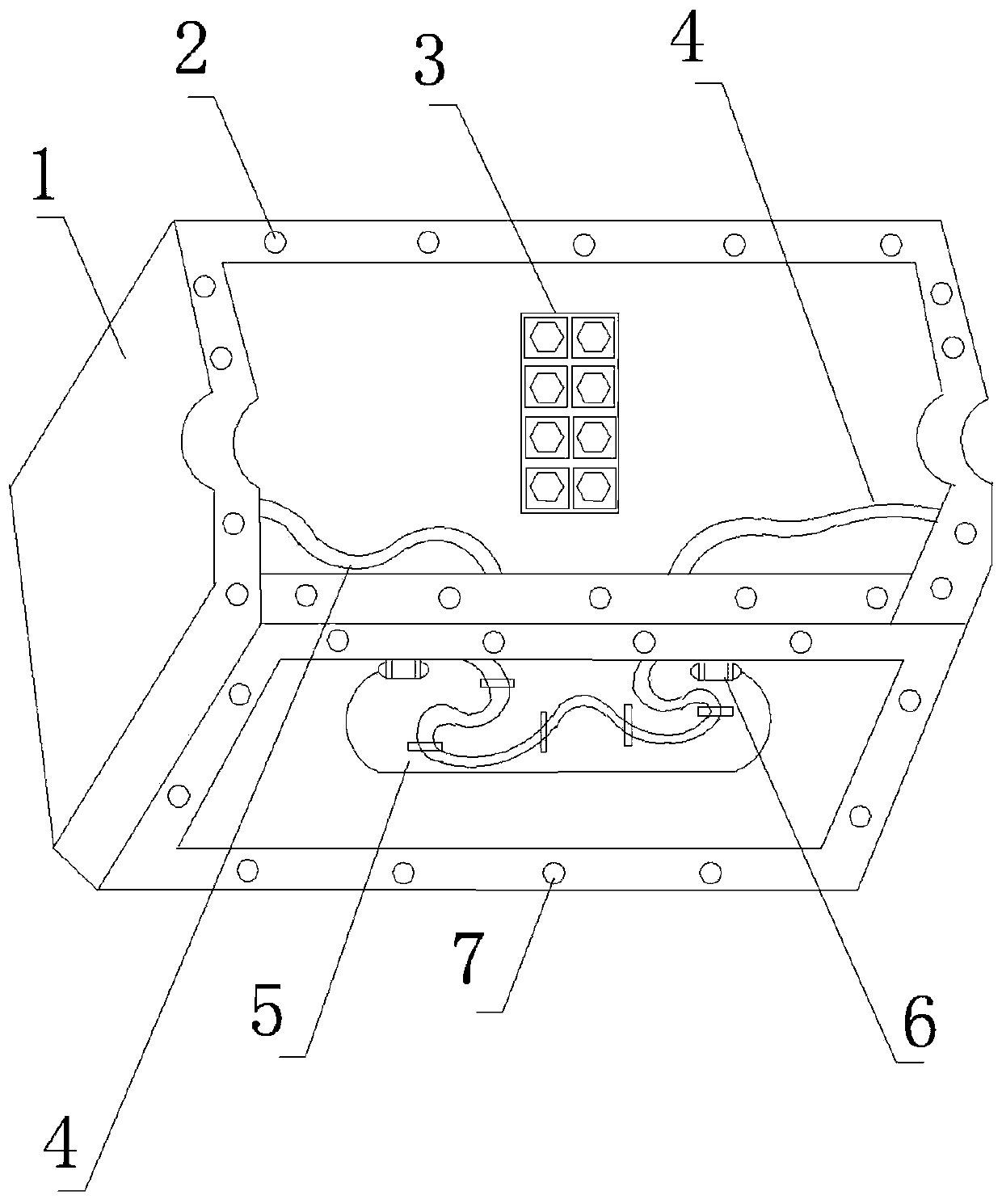

[0017] Such as figure 1 As shown, this optical fiber composite low-voltage cable connection device integrates electrical and optical connection side isolation, reduces the volume of the box body, facilitates installation and construction, and is safe and reliable for transportation and inspection. It includes: box body 1, cable terminal 3, fiber channel slot 4, splice tray 5, cover;

[0018] The cable terminal 3, the fiber channel slot 4, and the splice tray 5 are in the box body 1, and the cover is covered on the box body;

[0019] The cable separated after cutting the incoming line of the optical fiber composite low-voltage cable is connected to the left side of the cable terminal 3; the cable separated after the outgoing line of the optical fiber composite low-voltage cable is connected to the right side of the cable terminal 3;

[0020] The optical fiber composite low-voltage cable enters the separated optical fiber after cutting. After fusion splicing in the fiber fusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com