Mandulapalka harvester

A harvester and oily bean technology, applied in the field of agricultural machinery, can solve the problems of reduced harvesting effect, the oily bean harvester cannot achieve the effect of harvesting dry soil, etc., and achieves the effects of reasonable structure, reduced cost and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

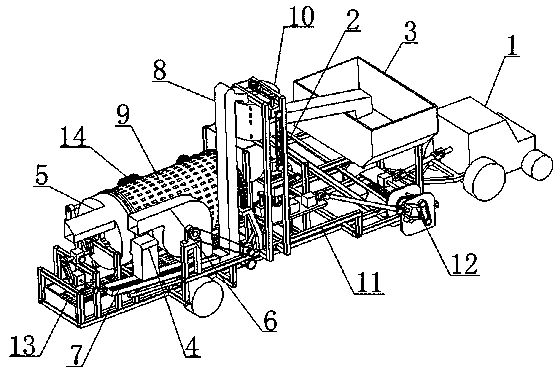

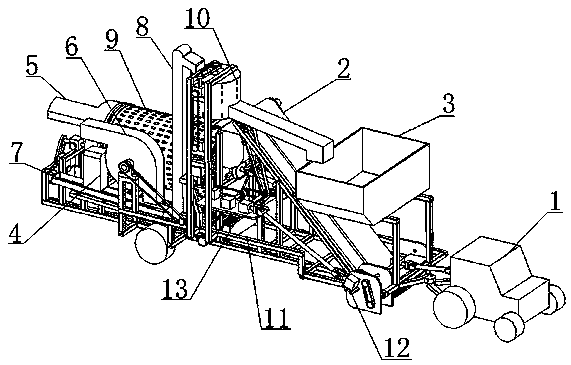

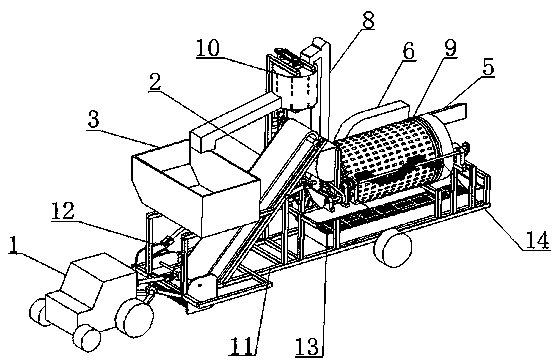

[0036] see Figure 1 to Figure 10 Shown, a kind of oily bean harvester comprises tractor 1, feeding device 2, collecting device 3, discharging device 4, the first suction fan 5, the second suction fan 6, inclined feeding device 7, vertical feeding Device 8, wet and dry separation soil removal device 9 and hair removal device 10, feeding device 2 is arranged on tractor 1, collection device 3 is arranged on tractor 1, and dry and wet separation soil removal device 9 is arranged on On the tractor 1 and the front end is connected with the feeding device 2, the first suction fan 5 is arranged at the rear part of the dry-wet dual-purpose separation and soil removal device 9, and the discharge device 4 is arranged on the first suction fan 5 and the dry-wet dual-purpose separation and removal device 9. Between the soil devices 9, the inclined feeding device 7 is arranged below the outlet of the discharge device 4, the second suction fan 6 is arranged above the inclined feeding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com