Dry and wet separation and soil removing device of Cyperus esculentus harvester

A wet and dry dual-purpose harvester technology, which is applied in the field of agricultural machinery, can solve the problems that the bean harvester cannot achieve the harvesting effect and the harvesting effect is reduced, and achieve the effect of reasonable structure, reduced labor intensity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

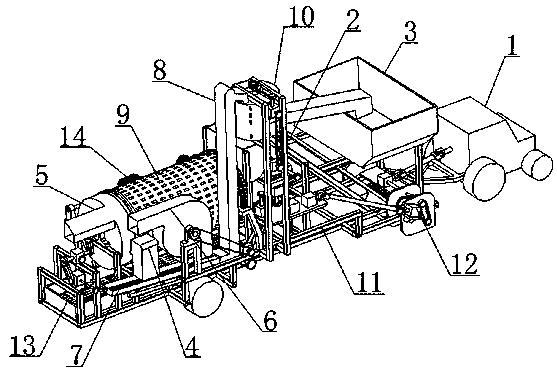

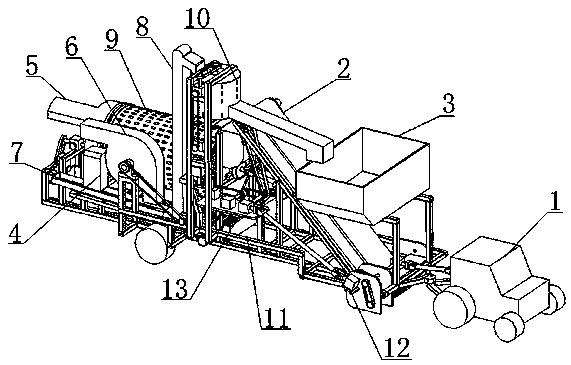

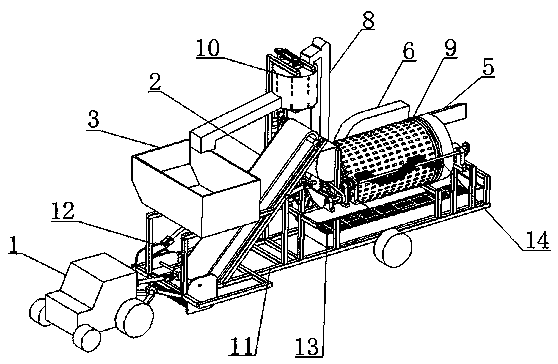

[0029] see Figure 1 to Figure 9 As shown, a dry-wet dual-purpose separation and soil removal device for the oily bean harvester includes a feed inlet 91, a first cylinder 92, a stirring rod 93, a second cylinder 94 and a shaft seat 95, and the feed inlet 91 Set on the tractor 1 and connected with the feeding device 2, the stirring rod 93 is set on the tractor 1 through the shaft seats 95 at both ends, the first cylinder 92 is arranged on the stirring rod 93, and the first cylinder 92 uses the stirring rod 93 is the axis rotation, the second cylinder 94 is arranged on the first cylinder 92, and the second cylinder 94 rotates with the first cylinder 92 as the axis;

[0030] The first cylinder 92 includes a first annular external gear 921, a first cylindrical body 922, a soil remover 923 and a baffle 924, the baffle 924 is arranged on the stirring rod 93, and the first annular external gear 921 is arranged On the baffle plate 924, the first annular external gear 921 rotates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com