A positioning and bending device for steel bars for construction engineering

A construction engineering and bending device technology, which is applied in the field of steel bar positioning and bending devices for construction engineering, can solve problems such as low efficiency, and achieve the effects of ensuring bending effect, improving cutting efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

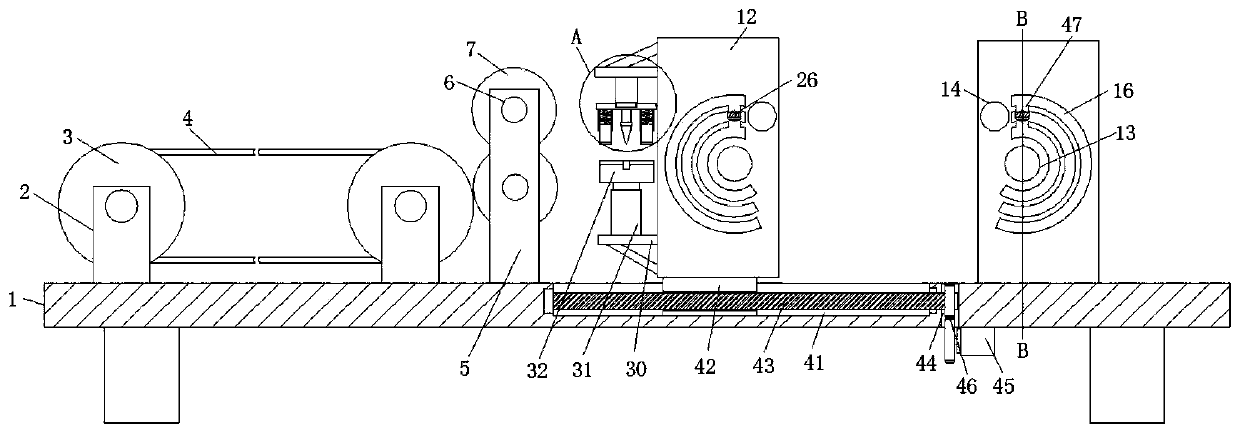

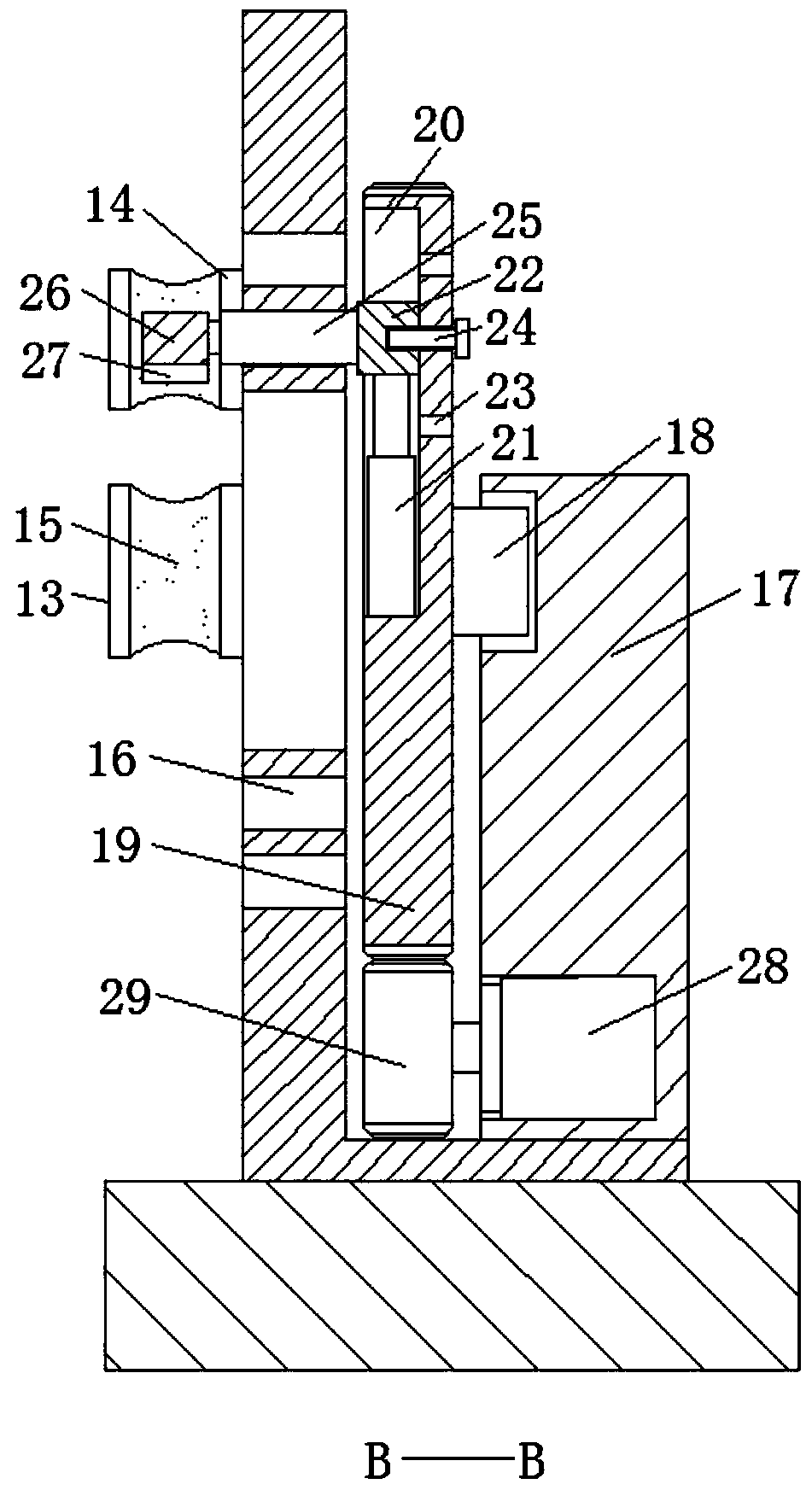

[0032] refer to Figure 1-6, a steel bar positioning and bending device for construction engineering, comprising a workbench 1, four corners of the lower end surface of the workbench 1 are welded with supporting legs, and a conveying mechanism is provided on one side of the upper end surface of the workbench 1, and the conveying mechanism is close to the workbench 1 One side of the center is provided with two supporting seats 5, and two supporting seats 5 are arranged and symmetrically fixed at the front and rear ends of the workbench 1. There are two, the outer wall of the rod of the positioning shaft 6 is fixedly connected with the positioning conveying roller 7 by screws, and the outer wall of the middle part of the positioning conveying roller 7 is provided with a limit groove 8, and the upper end surface of the workbench 1 is provided with bending plates 12 on both sides. , and the bending plate 12 is provided with two pieces and is arranged in an "L" shape, and the middl...

Embodiment 2

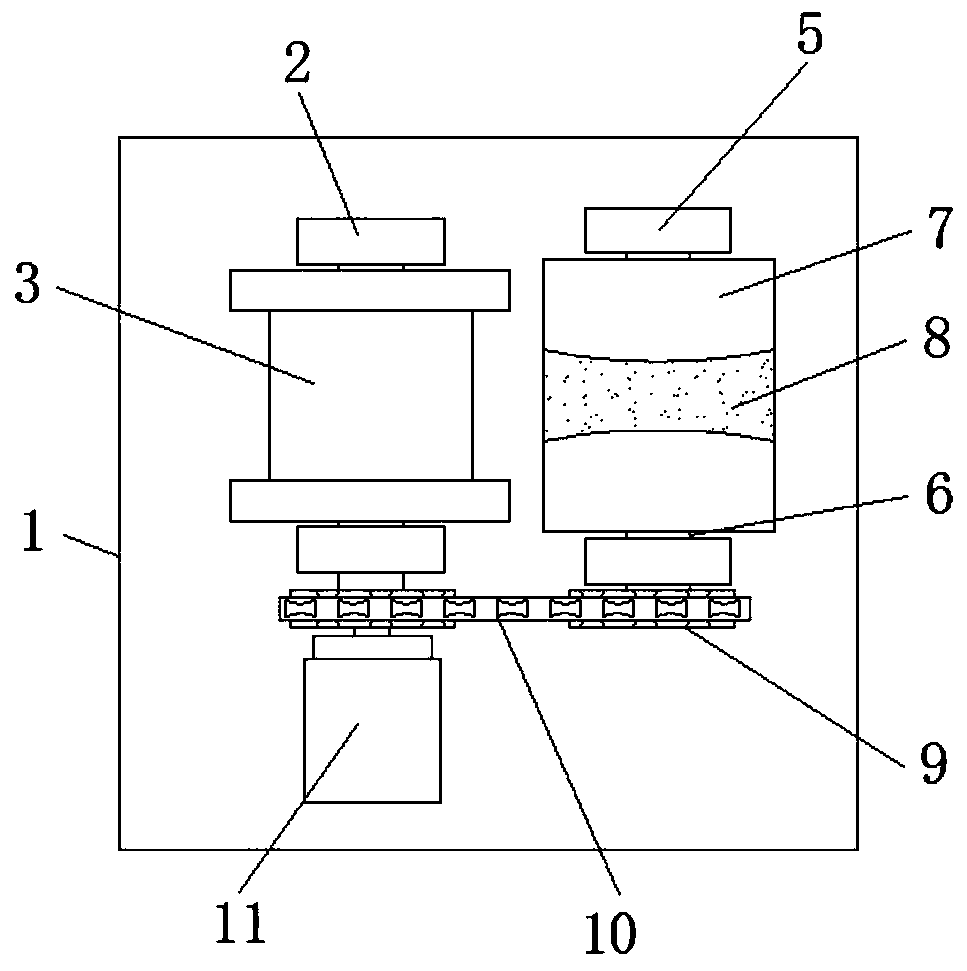

[0035] Such as Figure 1-2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the conveying mechanism includes a support base 2, and the support base 2 is provided with four and fixed on the upper end surface of the workbench 1 in a rectangular shape, two on the same side The upper end of support seat one 2 is all rotatably connected with belt pulley 3, is fixedly connected with conveyor belt 4 between two pulleys 3, and the front side of front end support seat one 2 and support seat two 5 is all fixedly connected with sprocket wheel 9, two Be connected with conveying chain 10 between sprocket wheel 9, and the rear side of rear end support base-2 is provided with servomotor-11, and the output end of servomotor-11 is fixedly connected with sprocket wheel 9 directly ahead.

[0036] In this embodiment, the rotation of the conveyor chain 10 is driven by the servo motor 11 to realize the rotation of the conveyor belt 4 and the positioning conveyor roller 7...

Embodiment 3

[0038] Such as figure 1 with 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bending groove 16 is a semicircular arc-shaped structure, and three bending grooves 16 are provided and distributed equidistantly on the bending plate 12. The three bending grooves 16 The upper part is also provided with a switching slot 47, and the switching slot 47 communicates with the three bending slots 16.

[0039] In this embodiment, three semi-arc-shaped bending grooves 16 are provided, and a switching groove 47 is provided on the upper part of the three bending grooves 16. The switching groove 47 communicates with the three bending grooves 16. Adjusting the position of the mounting block 22 facilitates the processing of steel bar elbows of different specifications, which brings convenience to production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com