Intelligentized production system for manufacturing chips

A production system and chip technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of unguaranteed processing accuracy and heavy labor, and achieve high work efficiency, high processing accuracy, and no Humanized bending and shearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

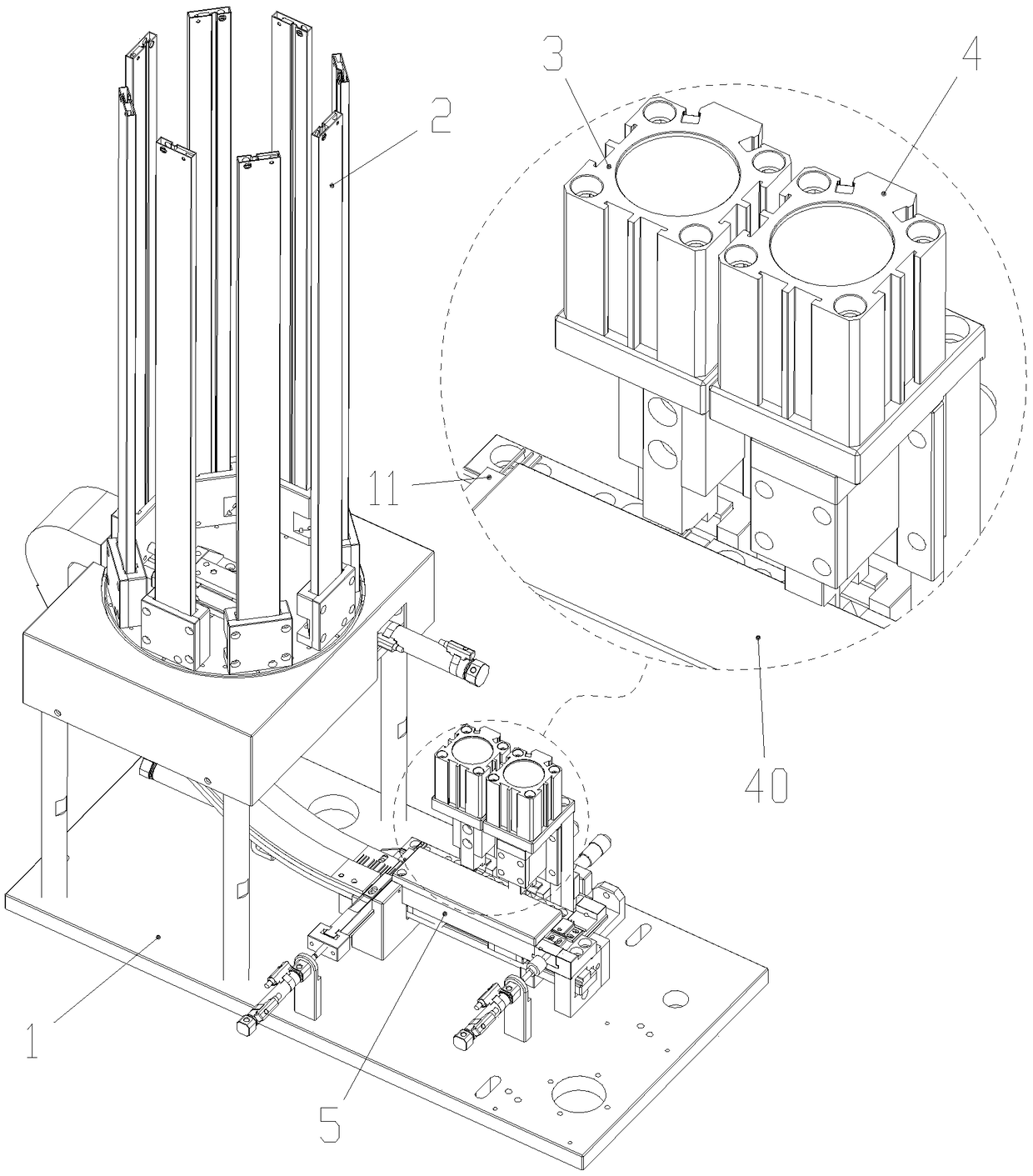

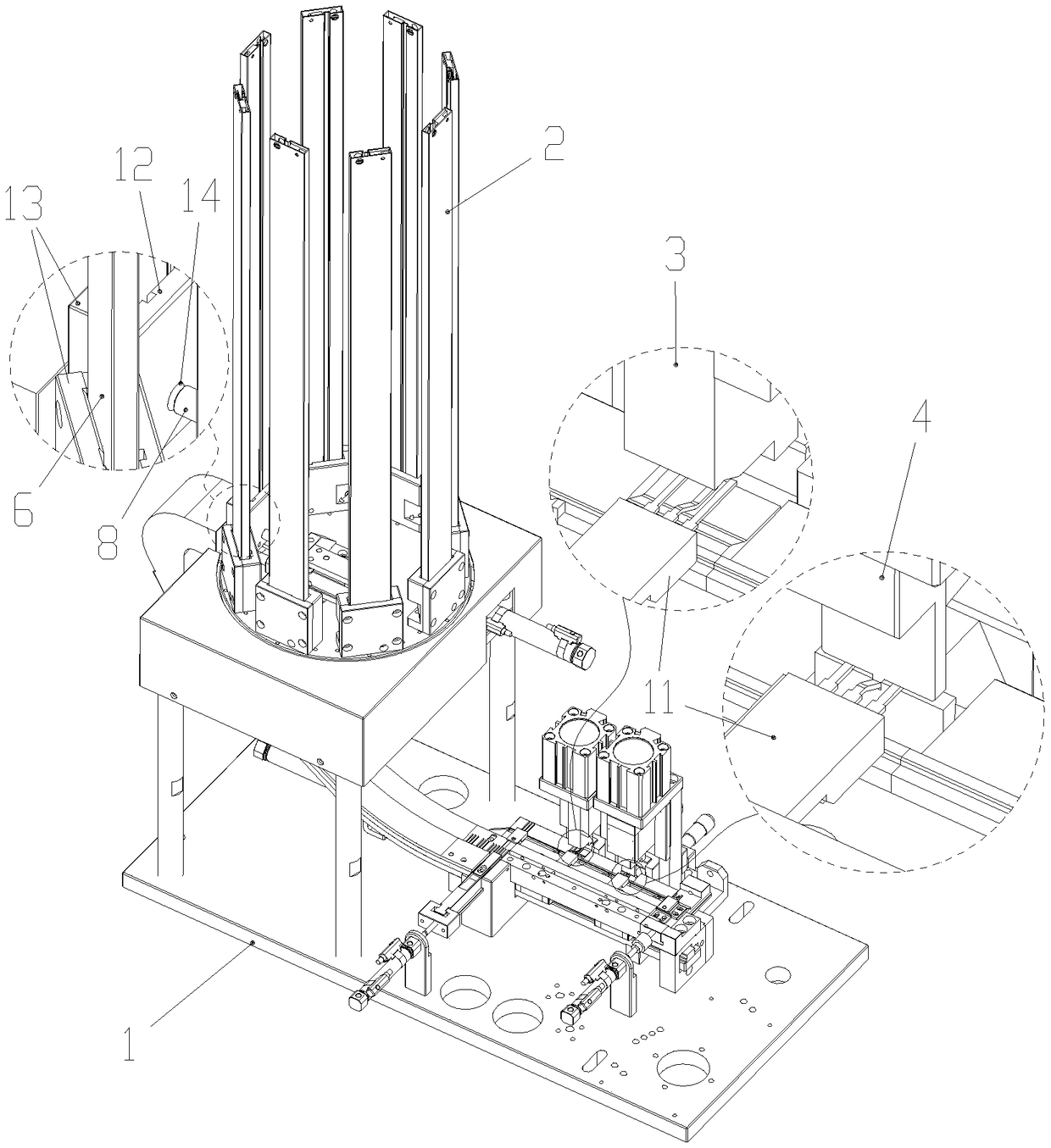

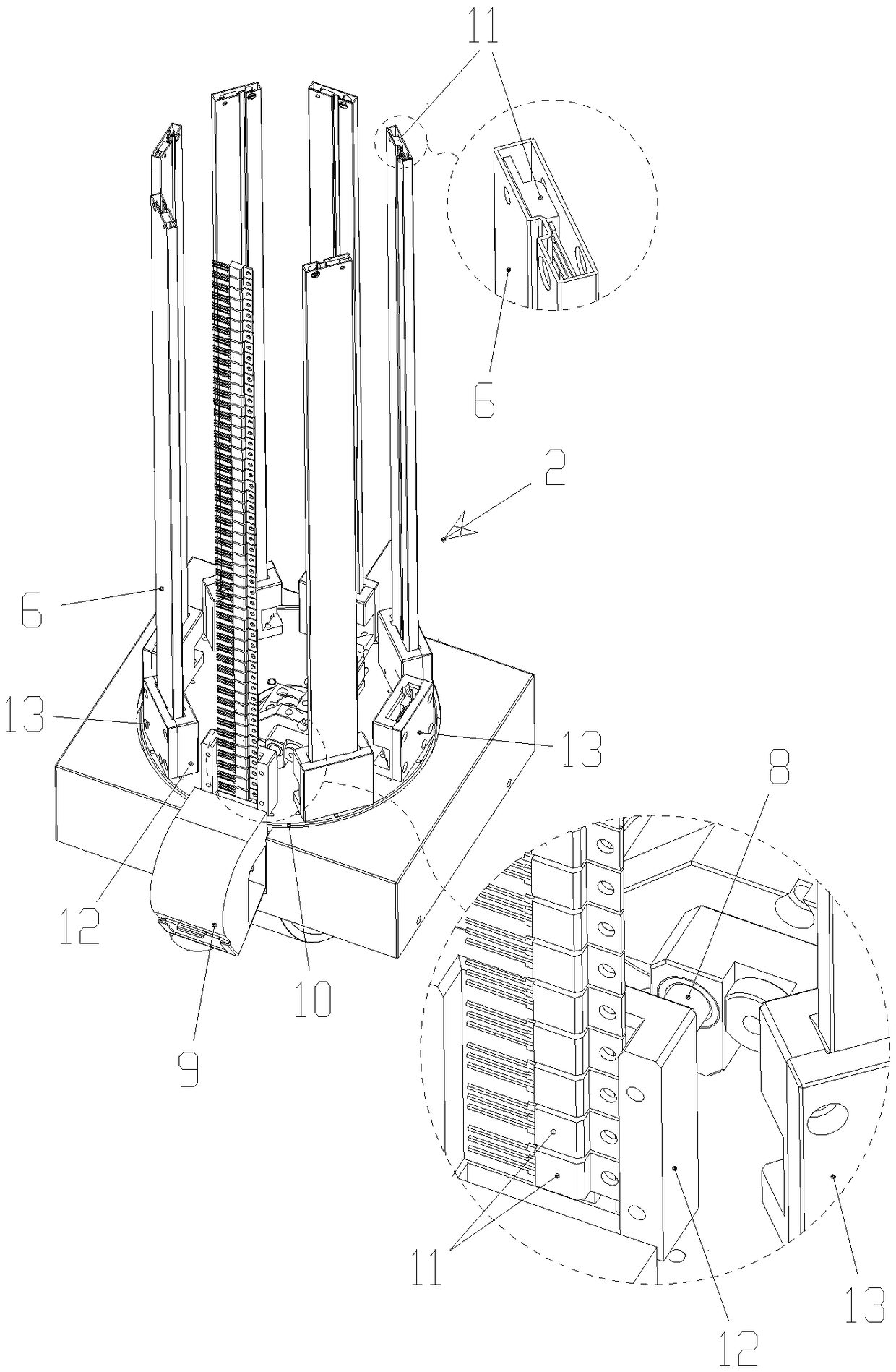

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides an intelligent production system for manufacturing chips, which is used to realize fully automatic bending and cutting of power chip pins, realize unmanned operation, high work efficiency, and high forming precision; The intelligent production system for manufacturing chips uses the feeding mechanism to transport the power chips to the stepping feeding mechanism through rails, and the bending mechanism and the shearing mechanism respectively complete the bending and cutting of the pins of the power chips.

[0031] figure 1 , 2 It is a structural schematic diagram of an intelligent production system for manufacturing chips according to the present invention, ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com