A ceramic hollow ball/titanium-based composite foam material and its centrifugal casting method

A technology of ceramic hollow balls and composite foam, which is applied in the direction of belts/chains/gears, rotors, engine components, etc., can solve the problems of unrealistic infiltration speed, poor uniformity, and low infiltration depth of metal liquid into the cavity, and achieve Easy product customization, easy mass production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

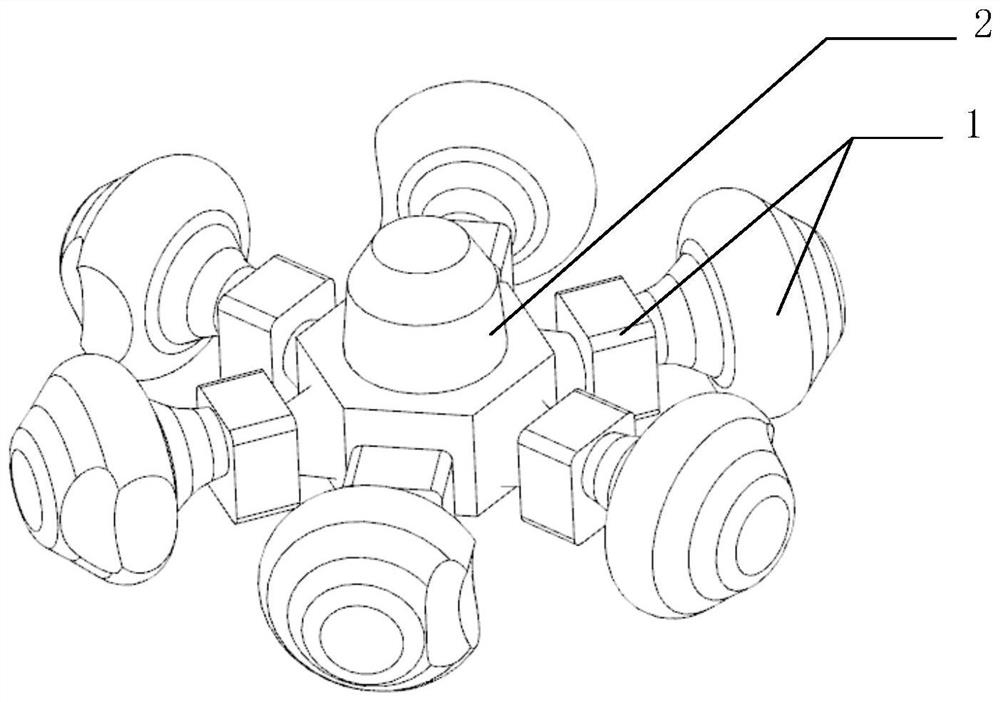

[0042] The centrifugal casting method of a kind of ceramic hollow sphere / titanium-based composite foam material in this embodiment comprises the following steps:

[0043] [Step 1]: According to the casting product structure, design the gating system, the three-dimensional model of the casting mold and the assembly process in sequence. According to the molding process, the three-dimensional model of the casting mold is split into three three-dimensional models of the casting mold parts, which are upper mold, lower mold and loose block. CNC machining equipment is used to process graphite-type parts according to the three-dimensional model of the cast parts. The cavity size of the graphite type is set according to the casting product and the pouring system, and at the same time, a filter screen placement slot is reserved at the position of the casting riser outside the corresponding cavity of the casting product in the graphite type; the loose block is used to fix the filter scre...

Embodiment 2

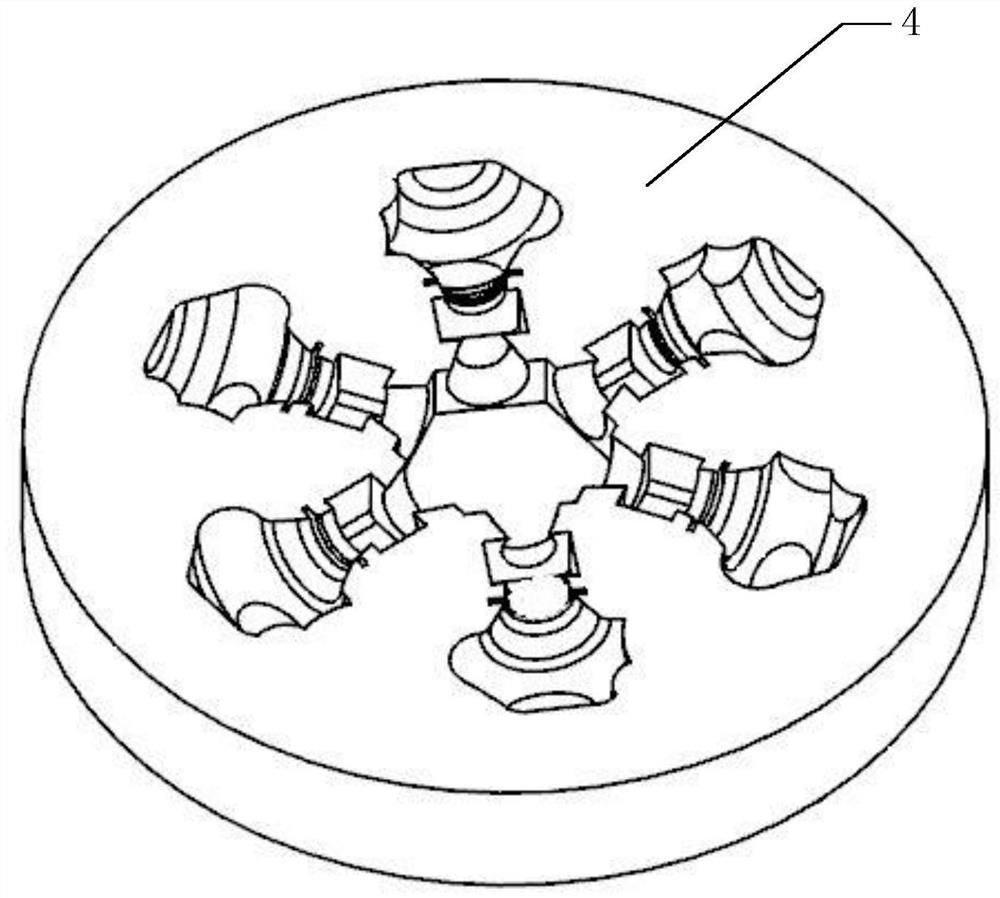

[0051] The centrifugal casting method of a kind of ceramic hollow sphere / titanium-based composite foam material in this embodiment comprises the following steps:

[0052] [Step 1]: According to the casting product structure, design the gating system, the three-dimensional model of the casting mold and the assembly process in sequence. According to the molding process, the three-dimensional model of the casting mold is split into multiple three-dimensional models of the casting mold parts, which are one or more upper molds, middle molds, lower molds and loose blocks. CNC machining equipment is used to process graphite-type parts according to the three-dimensional model of the cast parts. The cavity size of the graphite type is set according to the casting product and the gating system, and a filter screen placement slot is reserved in the inner gate area corresponding to the cavity of the gating system; the loose block is used to fix the filter screen, and the processed Graphi...

Embodiment 3

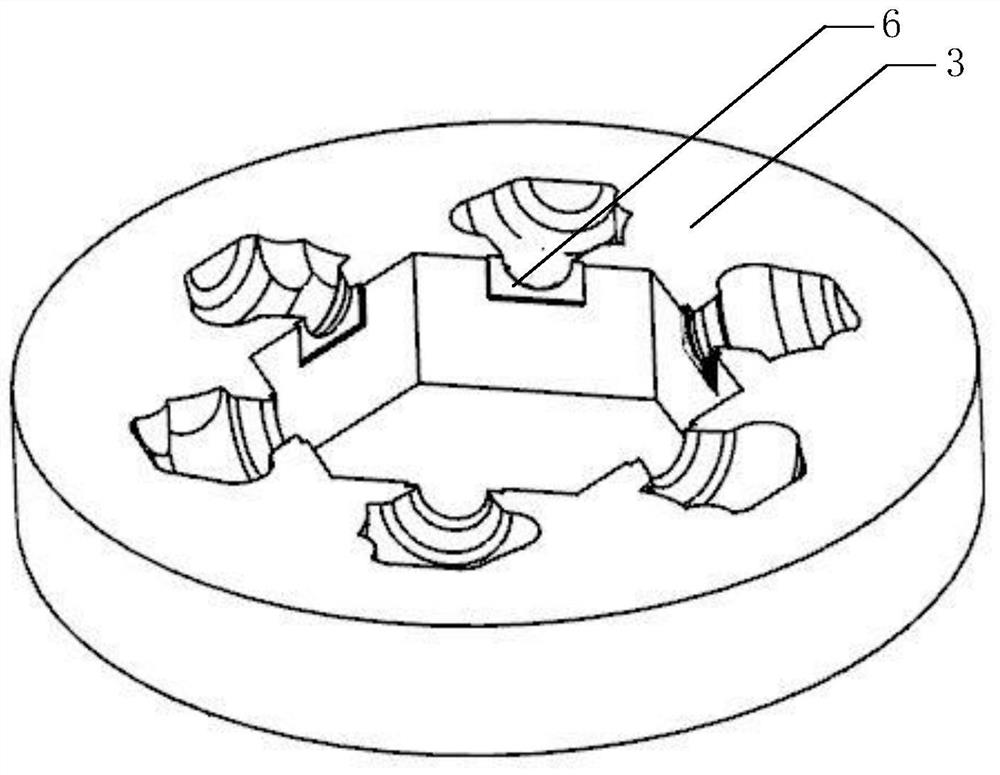

[0060] The centrifugal casting method of a kind of ceramic hollow sphere / titanium-based composite foam material in this embodiment comprises the following steps:

[0061] [Step 1]: Design the gating system and the three-dimensional model of the casting mold in sequence according to the casting structure, and use the mold modeling method to make a precision casting shell mold. The cavity size of the shell casting mold is set according to the casting product and the gating system.

[0062] [Step 2]: Prepare alumina ceramic hollow balls and high-temperature resistant ceramic filter screens with particle diameters in the range of 5-8mm, and put ceramic hollow balls and filter screens into the mold shell during the process of making the mold shell, or put After the shell mold is cut, put ceramic hollow balls and filter screens, and then assemble them, and put the shells equipped with ceramic hollow balls and ceramic filter screens into the degassing equipment for degassing.

[0063...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com