Multi-beam-assisted laser-arc composite welding method

A hybrid welding and arc technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of application limitations of high-intensity electromagnetic fields, and achieve the effects of preventing component segregation, ensuring stability, and suppressing nitrogen overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

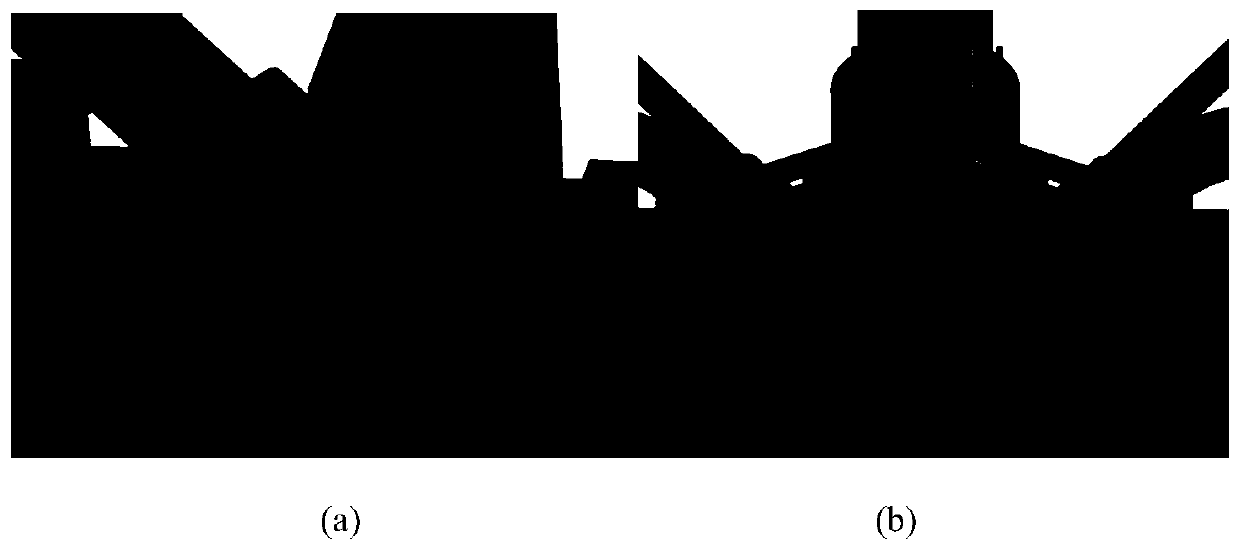

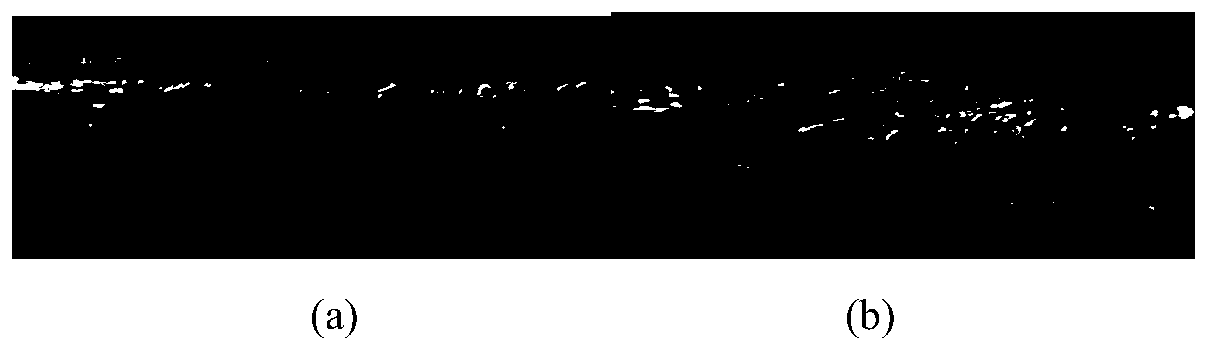

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: a kind of multi-beam assisted laser-arc hybrid welding method of the present embodiment, it is carried out according to the following steps:

[0028] Step 1: Before welding, according to the plate thickness, process the groove of the workpiece to be welded or directly perform surface cladding, grind and clean the processed groove or surface, and fix the polished and cleaned workpiece to be welded on the welding fixture superior;

[0029] Step 2: Use a clamp to rigidly fix the laser head and the arc welding torch. The angle between the axis of the welding torch and the base metal is 30-50°. Use a clamp to fix the powder feeding pipe around the nozzle of the welding torch. The number of powder feeding pipes is 3 to 6. The axis is aligned with the arc, and a conical tube can be added to the front end of the powder feeding tube to constrict the air flow, and each powder feeder is preset with 100g of required alloy powder;

[0030] Step 3: Set weldi...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that processing the groove refers to processing the part to be welded into a V-shaped groove, an I-shaped groove or a Y-shaped groove.

[0034] Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the laser is CO 2 Gas laser, YAG solid-state laser or semiconductor laser.

[0036] Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com