Intelligent robot welding system

A robot welding and welding area technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as easy failure and affecting welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

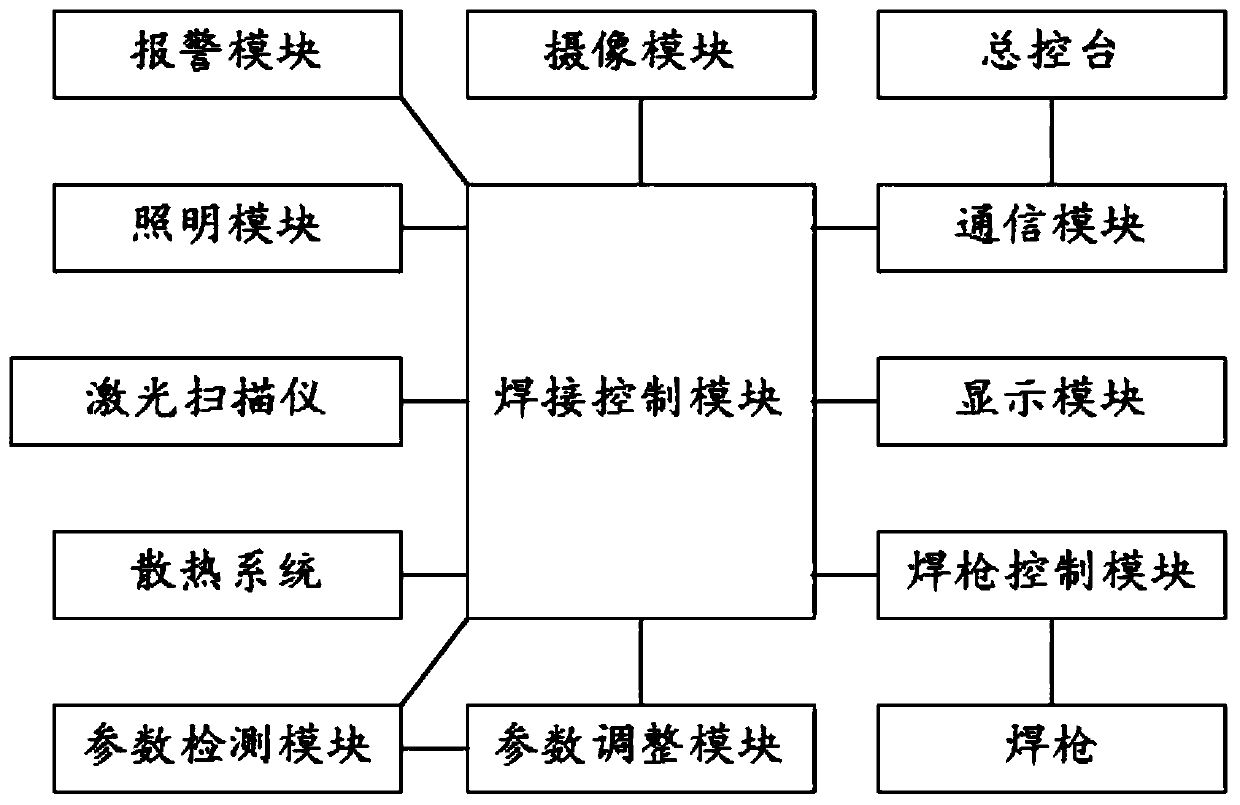

[0034] like figure 1 As shown, the present embodiment provides an intelligent robot welding system, which includes:

[0035] Laser scanner, used to scan and weld the area and obtain and upload various parameters or information of the welding area;

[0036] The parameter detection module is used to detect and record the welding parameters in the welding process;

[0037] The parameter adjustment module is connected with the parameter detection module, and is used for real-time adjustment of various parameters assembled during welding;

[0038] The welding control module is used to coordinate and direct the operation of the entire computer system;

[0039] The camera module is used to collect the image information of the welding area;

[0040] A welding torch control module is used to control the movement of the welding torch;

[0041] The communication module is used for remote wireless communication with the main console;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com