Fabricated building same-floor drainage pipe fitting

A same-layer drainage, prefabricated technology, used in buildings, pipes/pipe joints/pipes, pipes, etc., can solve the problems of easy to produce peculiar smell in the bathroom, unable to discharge safely, and reduce the safety of drainage, so as to improve the drainage flow of products, The effect of reducing the total thickness of the product and the simple structure of the water seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

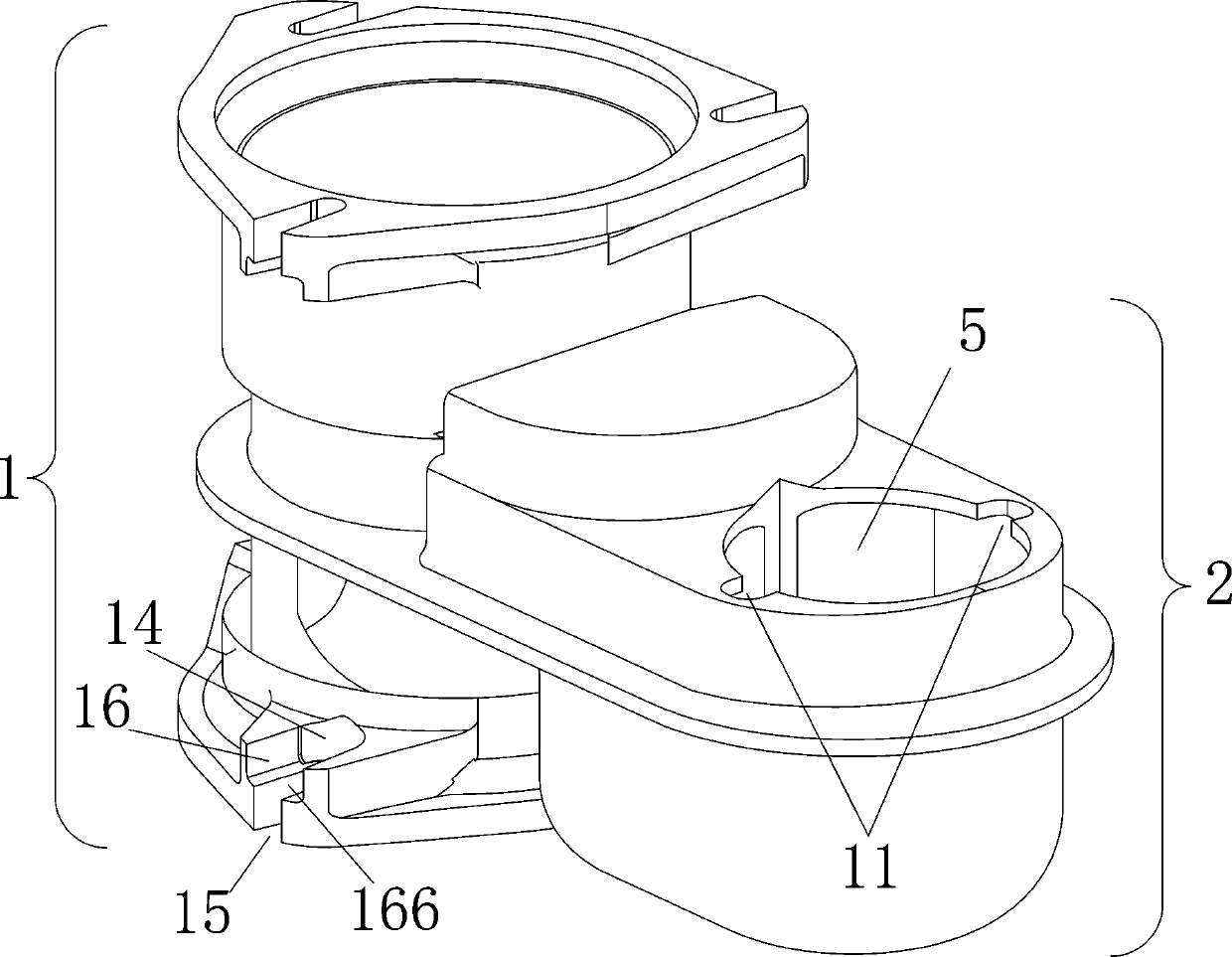

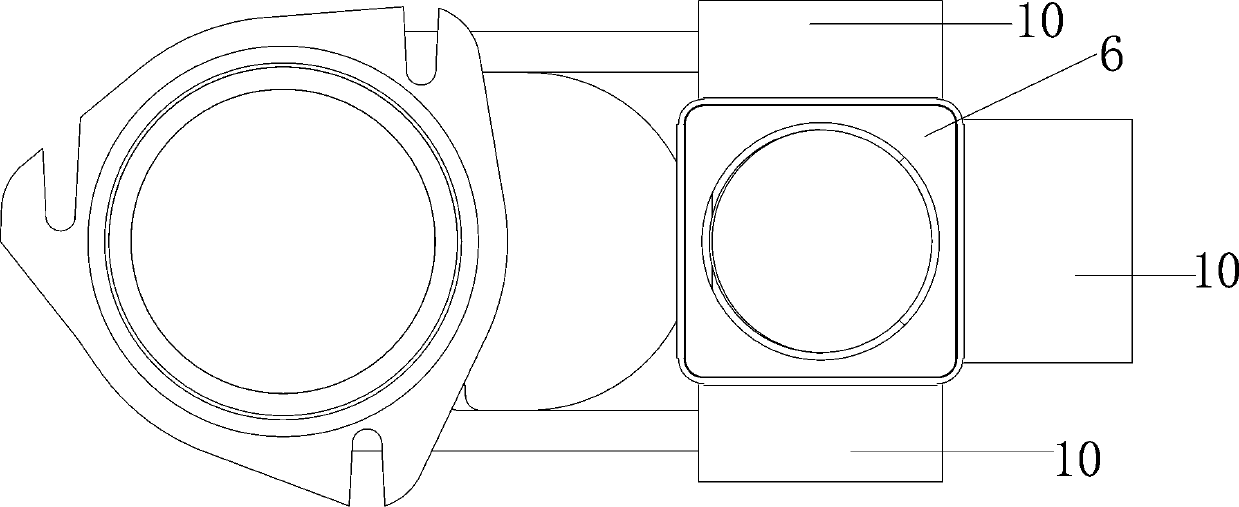

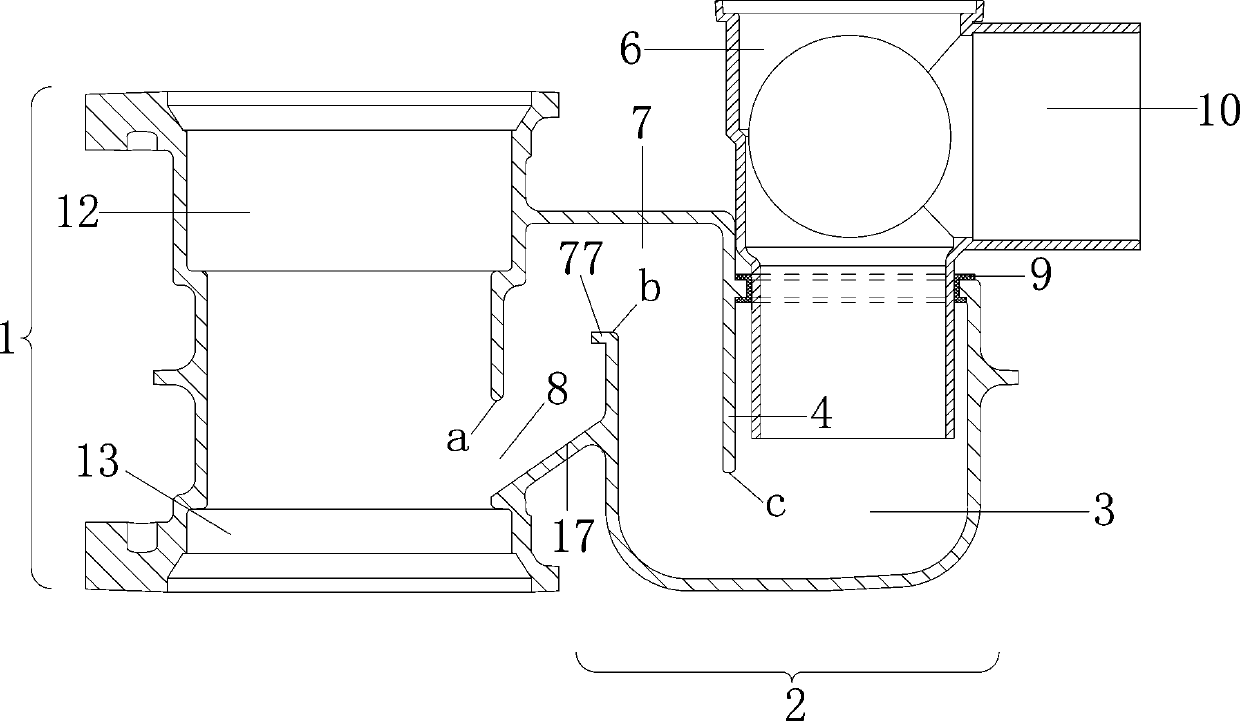

[0016] like figure 2 , 3 , 4, the prefabricated building same-floor drainage pipe fitting of the present invention is composed of a riser joint 1 and a horizontal pipe joint 2; The riser joint 1 is connected; the horizontal pipe joint 2 is composed of a water seal groove 3, a water seal baffle 4, a horizontal pipe drainage inlet 5 and a branch pipe interface 6; The lower end of the groove 3 is closed, and the upper end is close to the side wall of the riser joint 1. There is a port 7. The length of the longest horizontal part of the narrowest part of the port 7 is 100mm, and the longest vertical length is 30mm. The port 7 and the standpipe The drop of the Unicom port 8 of the joint 1 is 20mm; there is an anti-reflux ring plate 77 protruding toward the riser joint 1 outside the port 7; the length of the longest horizontal part of the Unicom port 8 is 100mm, and the longest vertical length is 30mm. The highest point a of the communication port 8 is 20 mm lower than the lowes...

Embodiment 2

[0018] like figure 2 , 3 , 4, the prefabricated building same-floor drainage pipe fitting of the present invention is composed of a riser joint 1 and a horizontal pipe joint 2. The riser joint 1 is connected up and down, and the horizontal pipe joint 2 is located on one side of the riser joint 1 and connected with the riser joint 1; the horizontal pipe joint 2 is composed of a water seal groove 3, a water seal baffle 4, a horizontal pipe drainage inlet 5 and a branch pipe interface 6 components; the outer wall of the water seal groove 3 is closed and the inner wall is connected with the riser joint 1, the lower end of the water seal groove 3 is closed, and the upper end is close to the side wall of the riser joint 1. The length of the pipe is 90mm, the longest vertical length is 35mm, and the drop between the port 7 and the communication port 8 of the riser joint 1 is 25mm; there is an anti-backflow ring plate protruding toward the riser joint 1 outside the port 7 77; the l...

Embodiment 3

[0020] like figure 1 As shown, in the same-floor drainage pipe fitting of the prefabricated building described in the present invention, there is an accumulated water discharge port 11 on the horizontal pipe drainage inlet 5 on the upper part of the water seal tank 3, and the accumulated water discharge port 11 is located at the water seal baffle 4 away from the riser joint Any position in 1 side, all the other are the same as embodiment 1,2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com