Assembly type large-span wooden beam string structure hoisting construction method

A construction method and large-span technology, applied in the direction of truss structures, girders, joists, etc., can solve the problems of structural components such as lateral instability, poor lateral stiffness, and weak overall stability, so as to ensure architectural effects and avoid Waste, the effect of ensuring the quality of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

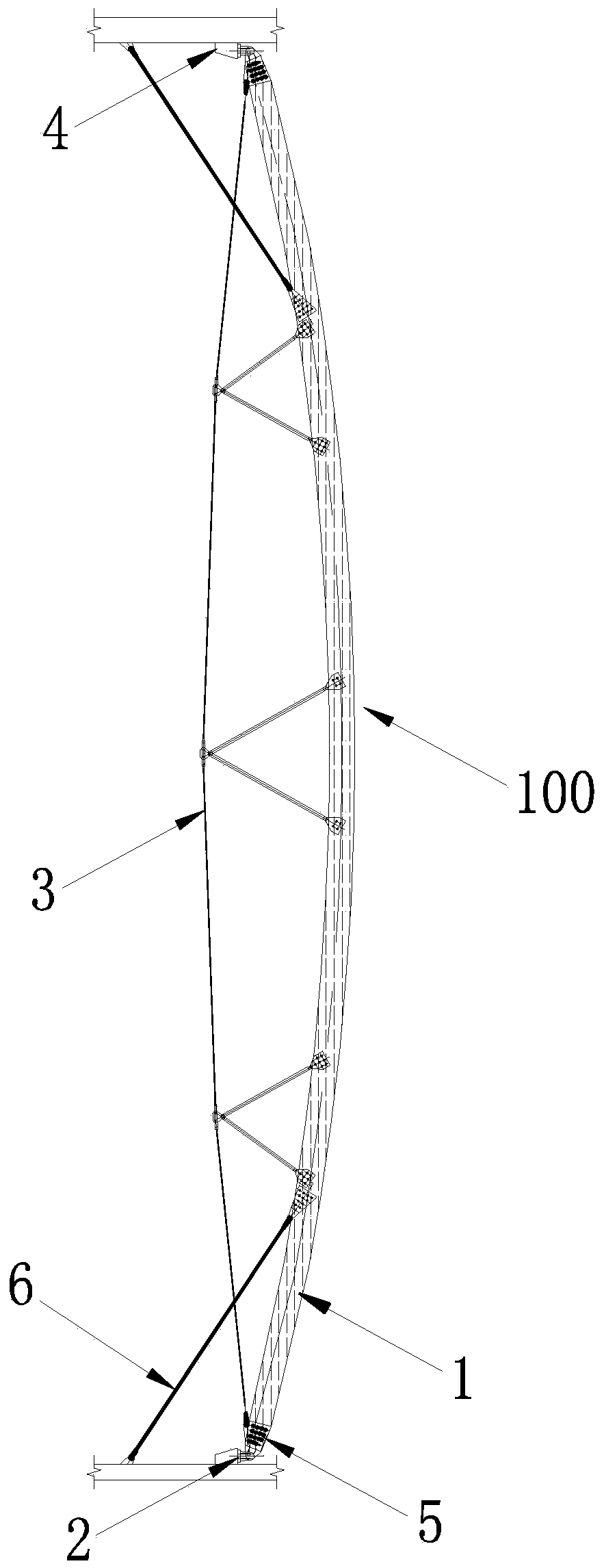

[0033] Such as figure 1 As shown, the overall schematic diagram of the assembled large-span wooden string string beam structure in the patent of the present invention. The beam ends of the prefabricated glulam string beam structure are spliced by wooden string beam sections. In this figure, each set of string beam ends is composed of 6 beam ends of the glued laminated wood string beam structure to realize the assembly of the string beams, thereby forming a large span Prefabricated glulam string beam structure. In the construction process, first construct the corbel 4 as shown in the figure, and weld the finished one-way movable basin rubber bearing or the fixed basin rubber bearing through the corbel welding to form a whole. The string string section 1 and the support 2 are connected by a pin, and the other end of the string beam section 1 is connected by a common bolt through a connecting plate 5; the cable 1 and the support connecting plate are connected as a whole by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com