Cascaded utilization system and method for waste heat of oxygen production process

A waste heat and cascade technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of ineffective utilization, inability to make full use of waste heat resources, and failure to take air temperature into account, so as to improve waste heat utilization efficiency and reduce maintenance Cost and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

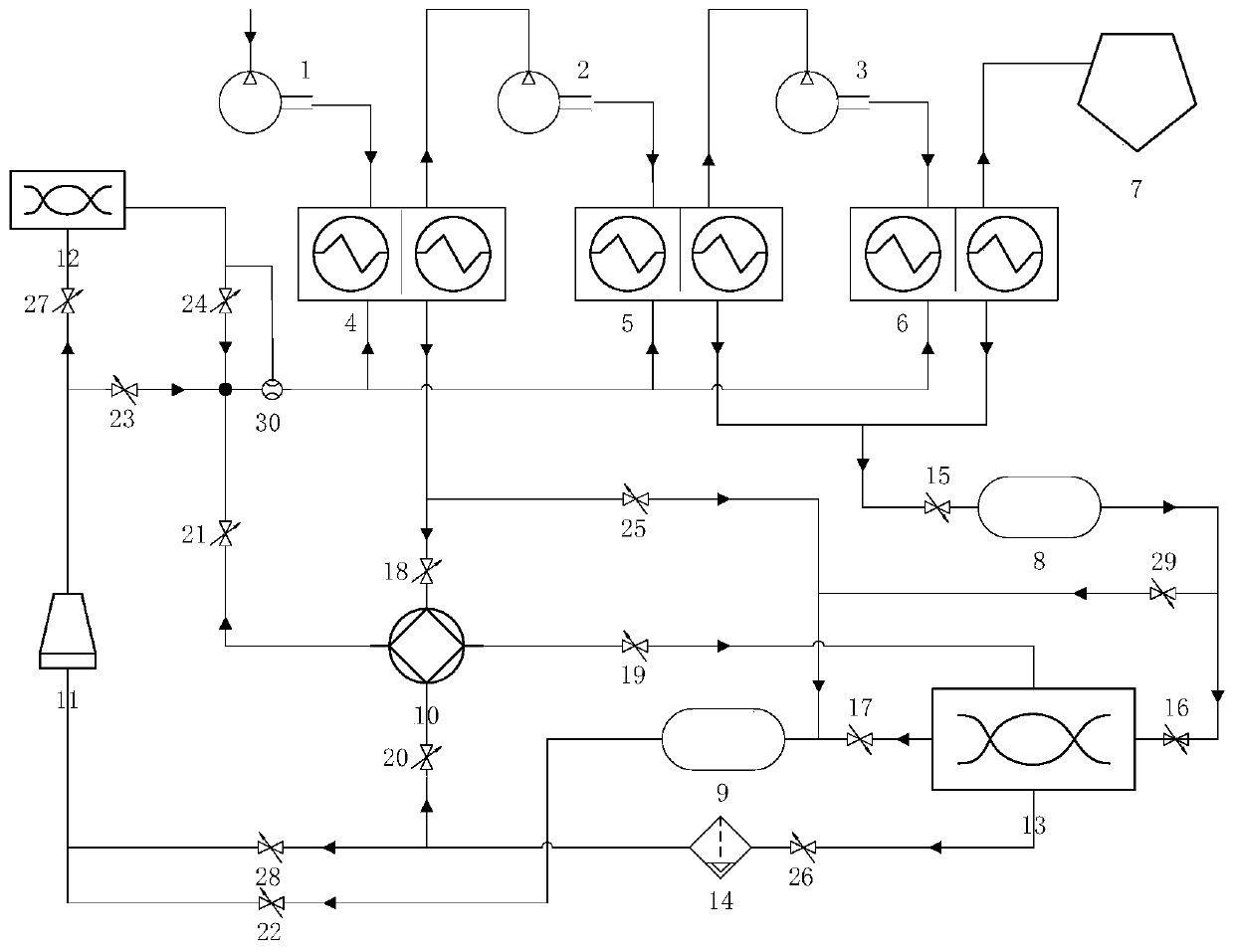

[0036] Low temperature heat exchanger non-operational mode:

[0037] In the non-operation mode of the low-temperature heat exchanger, the on-off valves 15, 16, 22, 23, and 25 are in an open state, and the on-off valves 19, 21, 28, and 29 are in a closed state; Valves 18, 20, 26, 27 are closed. The design maximum water storage capacity of the high temperature water storage tank 13 is 1800m 3 .

[0038] 150,000Nm 3 / h The normal temperature and normal pressure air passes through the primary compression 1 of the air compressor and the temperature reaches 95 °C, and then enters the primary heat exchanger 4 for heat exchange with 35 °C cooling water. After the heat exchange, the compressed air temperature is 40 °C and enters the air compressor. Two-stage compression, air compressor three-stage compression, the temperature of the two-stage compressed air and the third-stage compressed air can reach 120 ℃, after compression, it enters the second-stage heat exchanger 5 and the thir...

Embodiment 2

[0044] Low temperature heat exchanger operating mode:

[0045] In the low temperature heat exchanger operating mode, the on-off valves 15, 16, 19, 21, 23, 28 are in the open state, the on-off valves 22, 25, 29 are in the closed state; the on-off valves 18, 20, 24, 26, 27 are in In the open state, the on-off regulating valve 17 is in the closed state. The design maximum water storage capacity of the high temperature water storage tank 13 is 1800m 3 .

[0046] 150,000Nm 3 / h The normal temperature and normal pressure air passes through the primary compression 1 of the air compressor and the temperature reaches 95 °C, and then enters the primary heat exchanger 4 for heat exchange with 35 °C cooling water. After the heat exchange, the compressed air temperature is 40 °C and enters the air compressor. Two-stage compression, air compressor three-stage compression, the temperature of the two-stage compressed air and the third-stage compressed air can reach 120 ℃, after compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com