A kind of ag-agcl conductive paste capable of screen printing and preparation method thereof

A conductive paste, screen printing technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, material analysis by electromagnetic means, etc., can solve the problem that AgCl bulk crystals cannot be finely dispersed, Excessive addition, small addition of AgCl dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

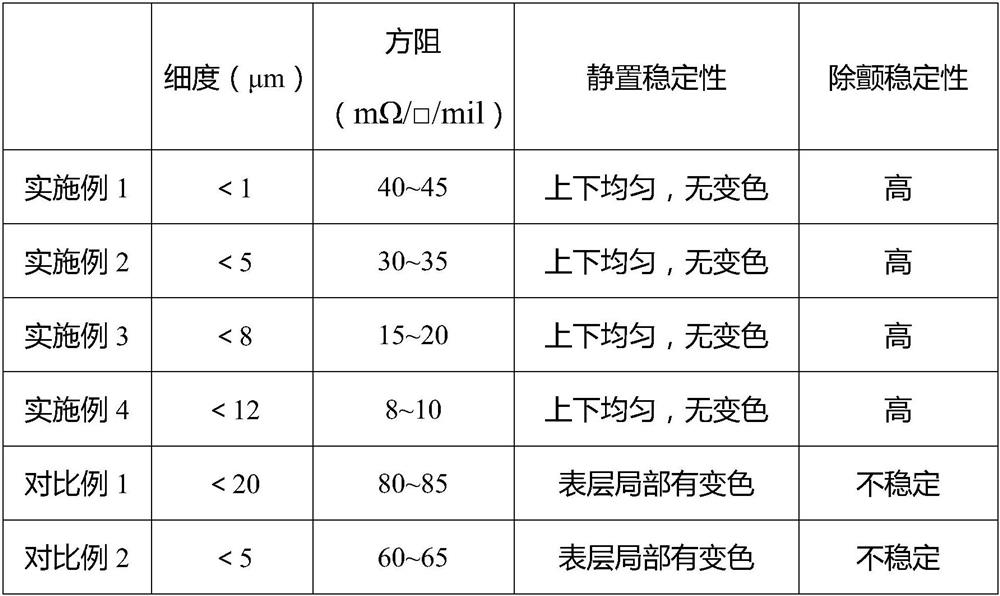

Examples

Embodiment 1

[0024] Step a: Preparation of Nano-AgCl Particles

[0025] 1 part of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder was dissolved in 39 parts of deionized water as a mother solution, and the temperature of the mother solution was controlled at 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 300nm.

[0026] Step b: Isolation of Nano-AgCl Particles

[0027] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0028] Step c: AgCl carrier preparation

[0029] Add the precipit...

Embodiment 2

[0033] Step a: Preparation of Nano-AgCl Particles

[0034] Dissolve 2 parts of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder in 38 parts of deionized water as a mother liquor, and control the temperature of the mother liquor to 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 200nm.

[0035] Step b: Isolation of Nano-AgCl Particles

[0036] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0037] Step c: AgCl carrier preparation

[0038]Add the precipitated AgCl partic...

Embodiment 3

[0042] Step a: Preparation of Nano-AgCl Particles

[0043] Dissolve 4 parts of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder in 36 parts of deionized water as a mother liquor, and control the temperature of the mother liquor to 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 120nm.

[0044] Step b: Isolation of Nano-AgCl Particles

[0045] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0046] Step c: AgCl carrier preparation

[0047] Add the precipitated AgCl parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com