Preparation method of magnetic nanoparticles with improved dispersion and particle uniformity

A technology of magnetic nanoparticles and uniform particles, which can be used in medical preparations with non-active ingredients, medical preparations containing active ingredients, nanotechnology for materials and surface science, etc., and can solve the problem of weakening the agglomeration effect of nanoparticles In order to prevent problems such as agglomeration, achieve good dispersion, prevent mutual agglomeration, improve dispersion and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of FE covering mesoporous silica 3 O 4 Nanoparticles

[0039]Put 10-15 nm Fe 3 O 4 Nanoparticles were dispersed in an aqueous solution of 0.1 wt% hydroxyethylcellulose at 100 ml of 50 ° C, and tetraeth escetate 10 ml of n-silicate, 25 ml of ethyl acetate was added, stirred for 10 min, and then dissolved for 10 min. - Aminopropyl-triethoxysilane 1.5 mL, maintaining the reaction liquid temperature of 65 ° C, stirring reaction for 24 hours, cooled, centrifuged, 6 times with ethanol, to obtain a surface covering mesoporous silica 3 O 4 Nanoparticles are split in water.

Embodiment 2

[0041] Silica-FE3O4 nano-core particles for preparing surface modified photosensitizers

[0042] Under the prevention of light, a 5.4 g of a hematoporphoporphoporphin-sensitive agent was dissolved in 100 mL DMF, weighted 4.2 g of EDC in 100 mLDMF, weighing 7.2 g of NHS dissolved in 100 ml DMF, combined with the above DMF solution, and activated at room temperature 4. In the animation, 2.5 g of methylpropylpropyltrimethoxysilane and 6 mmol of 6 mmol were dispersed in the solution were added to the surface of the surface of the above-described surface coating. 3 O 4 Nanoparticles, the dispersion solution is 0.1 wt% hydroxyethylcellulose aqueous solution; oscillating reaction overnight, dispersion, deionized water washing, dry, to obtain a mesoporous silica surface modified photosensitive Fe 3 O 4 Nanoparticles.

Embodiment 3

[0044] Magnetic nanoparticles with improved dispersibility

[0045] 3-5 nm nano gold particles were dispersed in 20 ml of DMF, weighted 1.2 g of EDC dissolved in 40 ml of DMF, weighed 2.0 g of NHS dissolved in 40 ml of DMF, combined with the above DMF solution, and activated at room temperature for 4 hours, activated The formation of a mesoporous silica surface modified photosensitive agent 3 O 4 The PVA / PVP composite dispersion of nanoparticles, wherein the PVA concentration in the dispersion is 0.2% by weight, the PVP concentration is 0.05 wt%; the oscillating reaction is overnight, dispersion is discarded, and the deionized water is cleaned, and ultrasonic dispersion in deionized water 15min, centrifugation, magnetic nanoparticles.

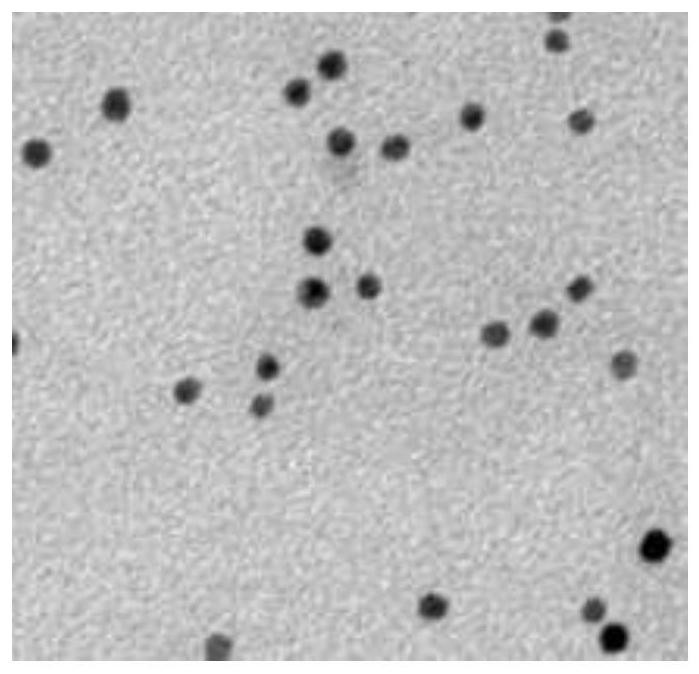

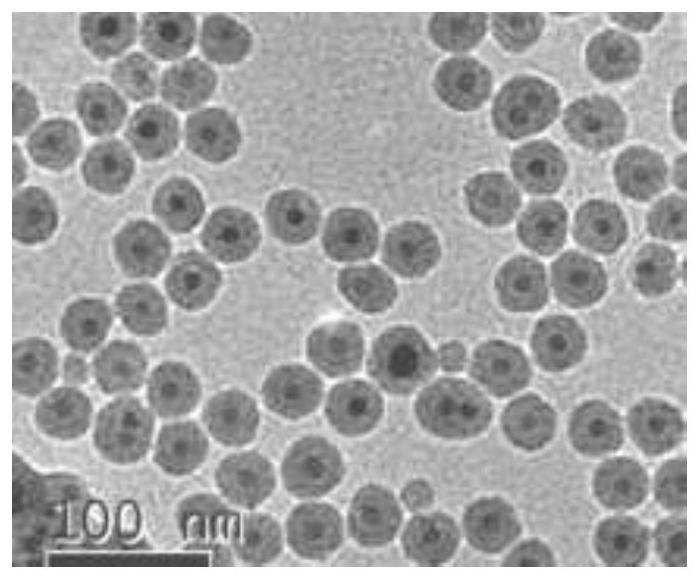

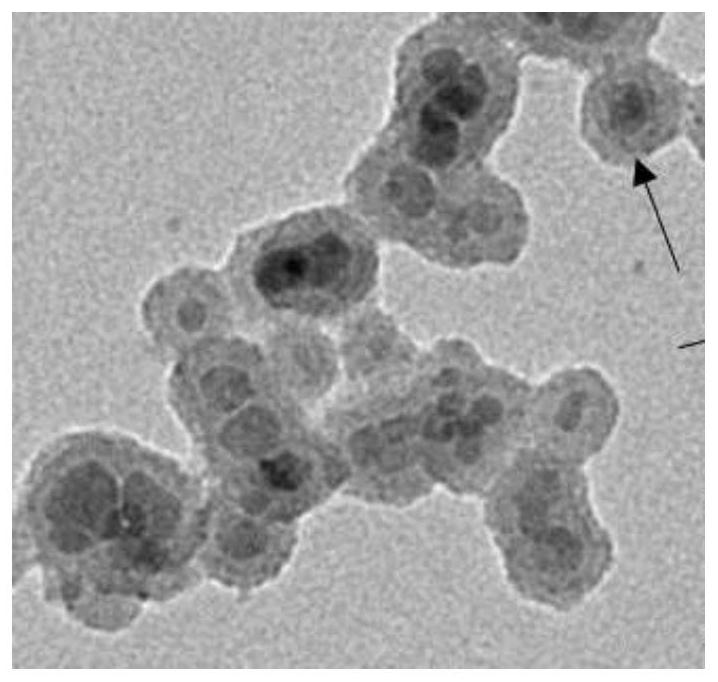

[0046] The prepared magnetic nanoparticles were characterized by TEM. From figure 2 The characterization results show that the prepared nanoparticles have a significant nuclear shell structure, the particles are spherical, the particle size is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com