Reactor and method for continuously synthesizing epoxy chloropropane

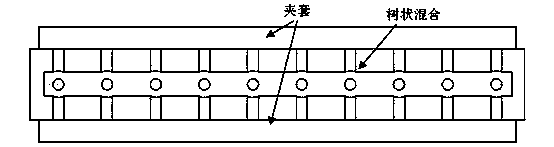

A tubular reactor and mixer technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical fixed reactors, etc., can solve the problems of large waste water, energy consumption and Problems such as high operating cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Stir the catalyst and allyl chloride in the catalyst dispersion tank evenly, the dosage of the catalyst is 5% of the mass of allyl chloride, and the concentration of hydrogen peroxide is 50%. In the tubular reactor, the reaction temperature is controlled at 45°C; the mixed material enters the tubular reactor to contact, mix, and react with hydrogen peroxide; the reaction controls the material flow rate, and the residence time is 2h; after the reaction process is completed, the effluent leaving the reaction zone is Epichlorohydrin reaction solution.

[0041] (2) Analyzing the epichlorohydrin reaction solution, the conversion rate of hydrogen peroxide was 98.5%, and the yield and selectivity of epichlorohydrin were 90.8% and 99.1%, respectively.

Embodiment 2

[0043] (1) Stir the catalyst and allyl chloride in the catalyst dispersion tank evenly, the dosage of the catalyst is 5% of the mass of allyl chloride, and the concentration of hydrogen peroxide is 30%. In the tubular reactor, the reaction temperature is controlled at 50°C; the mixed material enters the tubular reactor to contact, mix, and react with hydrogen peroxide; the reaction controls the flow rate of the material, and the residence time is 2h; after the reaction process is completed, the effluent leaving the reaction zone is Epichlorohydrin reaction solution.

[0044] (2) Analyzing the epichlorohydrin reaction solution, the conversion rate of hydrogen peroxide was 98.5%, and the yield and selectivity of epichlorohydrin were 94.7% and 96.1%, respectively.

Embodiment 3

[0046] (1) Stir the catalyst and allyl chloride in the catalyst dispersion tank evenly, the dosage of the catalyst is 10% of the mass of allyl chloride, and the concentration of hydrogen peroxide is 50%. In the tubular reactor, the reaction temperature is controlled at 50°C; the mixed material enters the tubular reactor to contact, mix and react with hydrogen peroxide; the reaction controls the material flow rate, and the residence time is 4h; after the reaction process is completed, the effluent leaving the reaction zone is Epichlorohydrin reaction solution.

[0047] (2) Analyzing the epichlorohydrin reaction solution, the conversion rate of hydrogen peroxide was 99.5%, and the yield and selectivity of epichlorohydrin were 95.6% and 96.1%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com