Intelligent flexible full-rotation overturning and dipping and conveying device and vehicle body pretreatment electrophoretic overturning and dipping system

A conveying device, intelligent and flexible technology, applied in the direction of conveyors, electrophoretic coating, conveyor objects, etc., can solve the problem of inability to realize different process optimization, large tank volume of suspended conveyor system, large floor space of coating line, etc. problems, to achieve the effect of shortening the length of equipment, simplifying operation and maintenance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be more clearly defined.

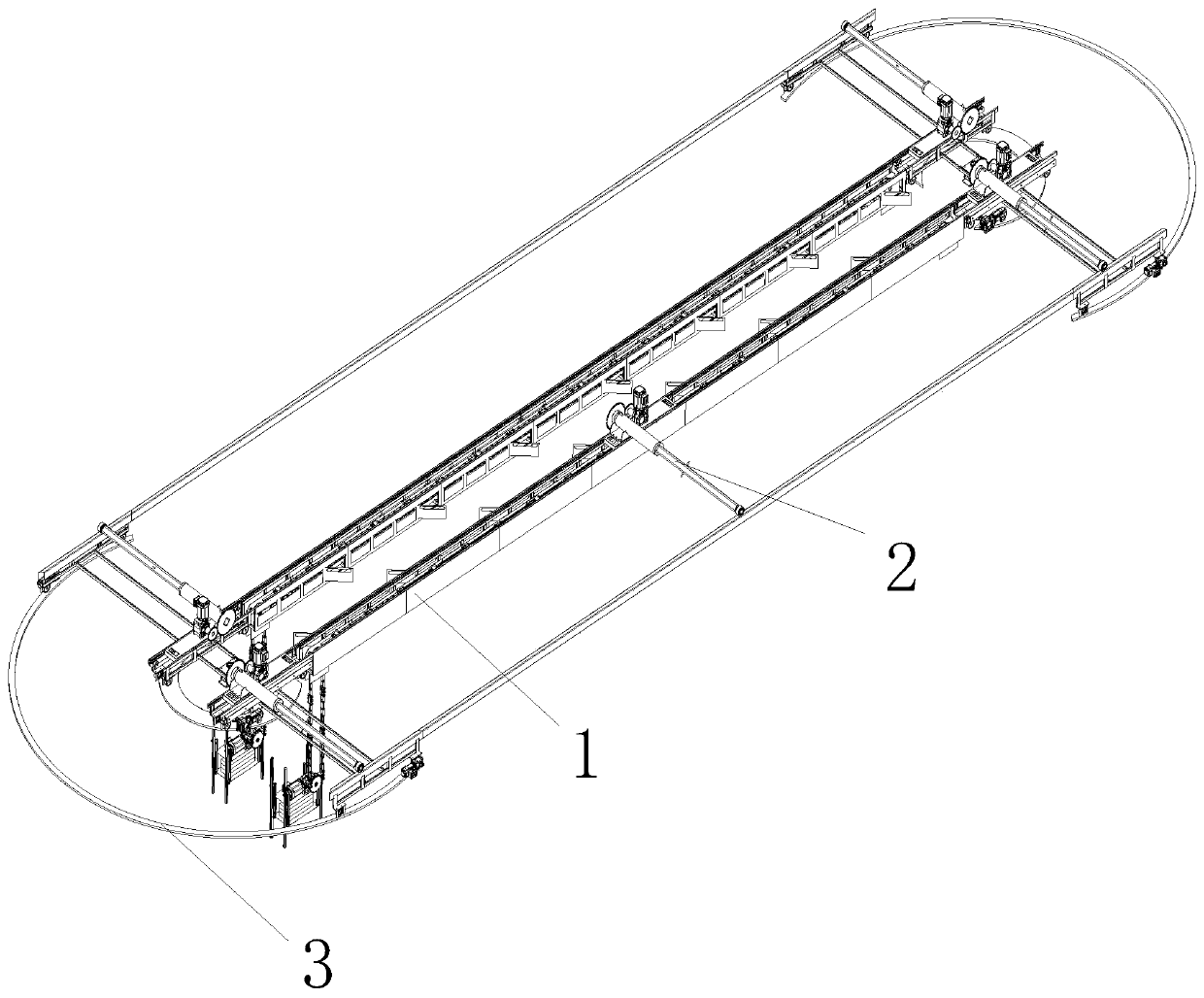

[0037] Such as figure 1 The intelligent flexible full-rotation turning and immersion conveying device shown includes a track mechanism 1, a turning mechanism 2 that is arranged on the track mechanism 1 and can move along the track mechanism 1, and is arranged at the inlet and outlet ends of the track mechanism 1 and can achieve 180 For the rotating trolley with a degree of rotation, one or more sets of turning mechanisms 2 can be set on each track mechanism 1 according to the needs to improve production efficiency.

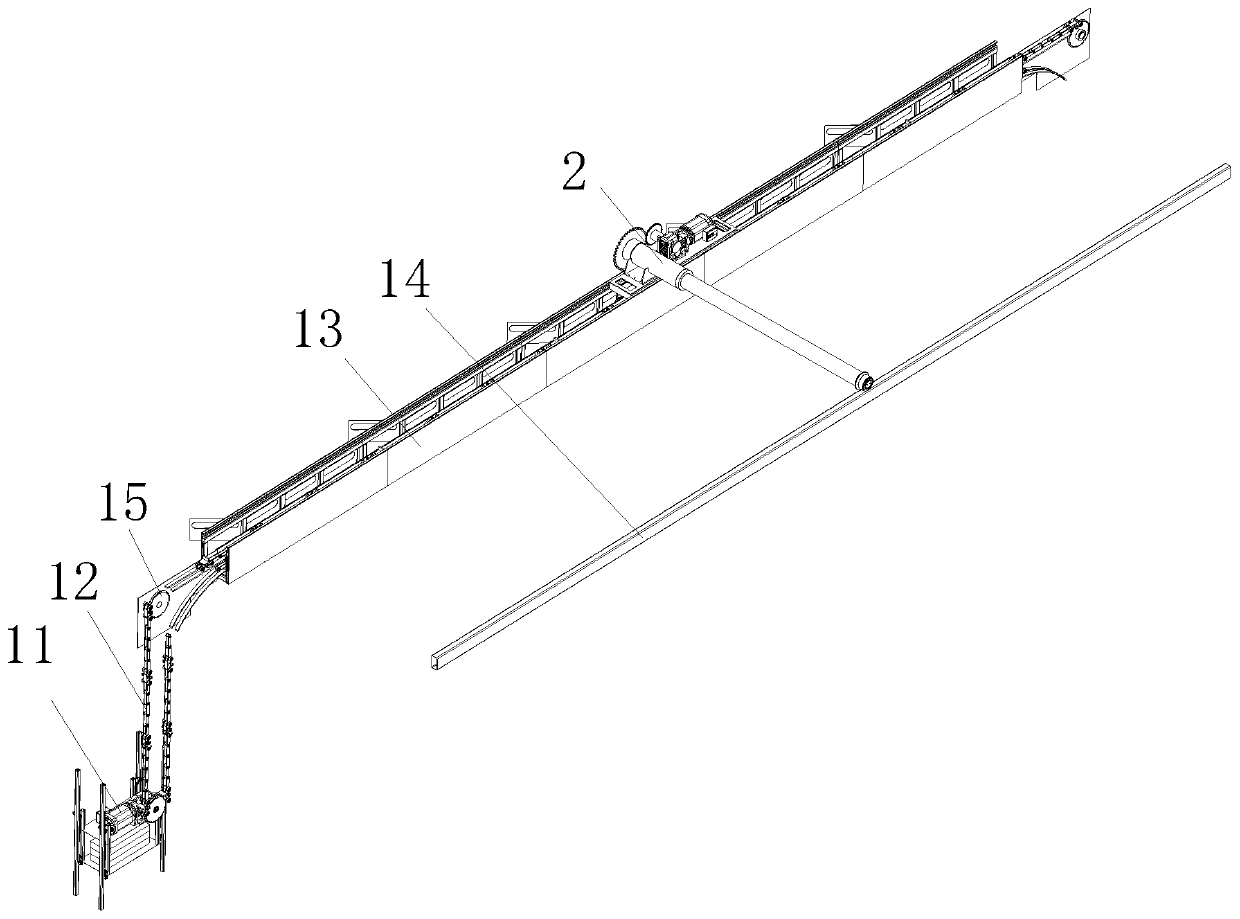

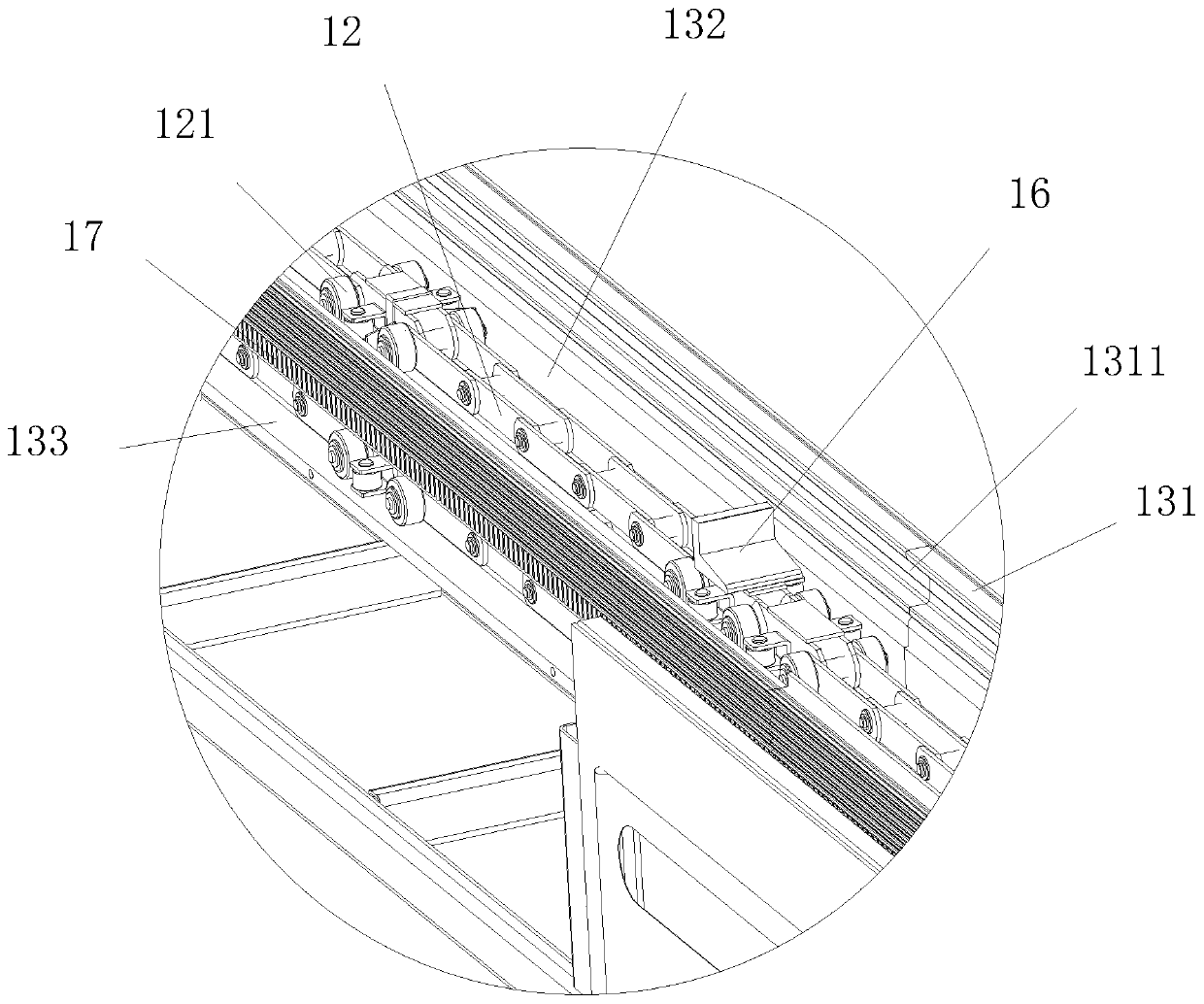

[0038] Such as figure 2 As shown, the track mechanism 1 includes an active track and a driven track 14 parallel to the active track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com