Production method of polypropylene resin with high melt index, high impact resistance and high rigidity

A polypropylene resin and a production method technology are applied in the field of polypropylene production to achieve the effects of increasing melt index, ensuring impact strength and rigidity, and increasing crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

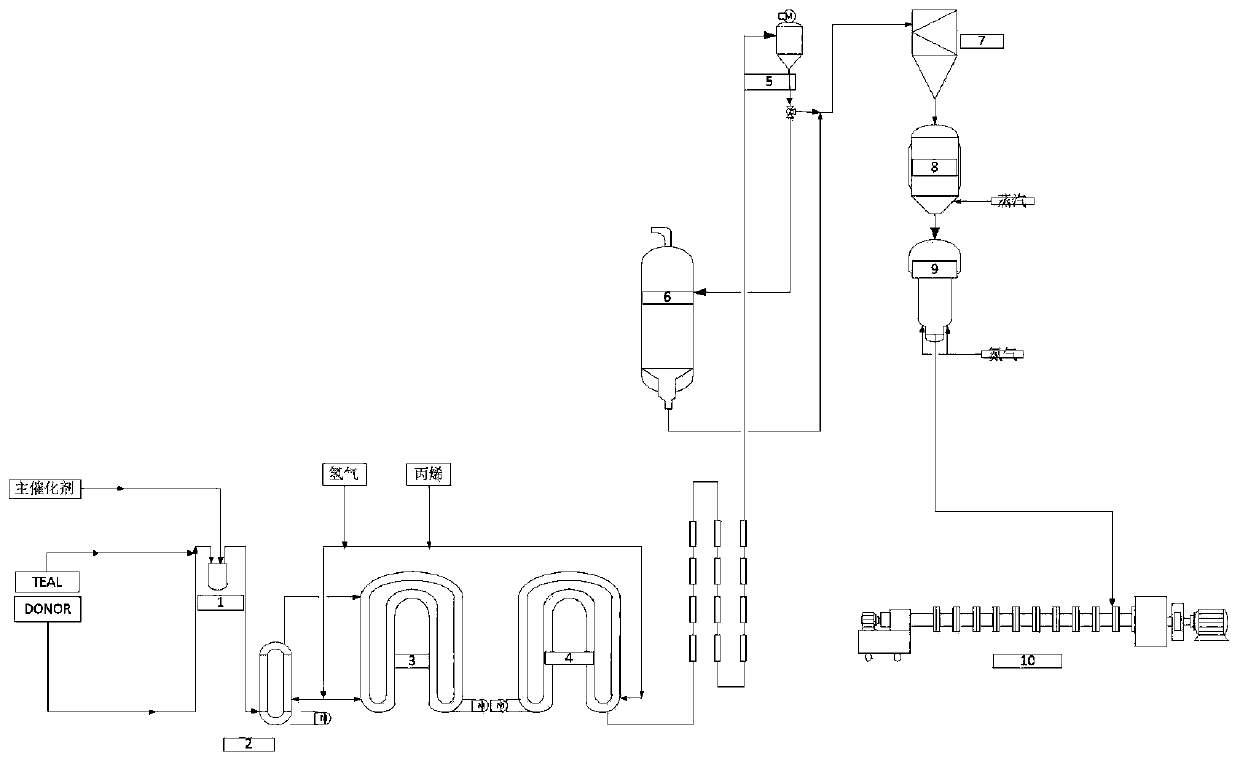

[0033] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] This embodiment proposes a production method of high melting point, high impact resistance and high rigidity polypropylene resin, its principle is as follows figure 1 As shown, the Spheripol second-generation process technology combined with two series loop reactors and a gas phase copolymerization tank reactor is used. The method specifically includes the following steps:

[0035] S1, polypropylene particles are activated in the precontact tank 1 by main catalyst, cocatalyst triethylaluminum TEAL and cocatalyst electron donor DONOR (wherein, the feeding amount is controlled by instrument mass flowmeter respectively, triethylaluminum / The electron donor ratio is 1-30, and the co-catalyst compound electron donor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com