Instruments and methods for in-situ testing of mechanical properties of materials under high temperature and complex mechanical loads

A technology of mechanical load and material mechanics, which is used in scientific instruments, instruments, and the use of repetitive force/pulse force to test the strength of materials, etc., to achieve the effect of preventing oxidation, wide loading range, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

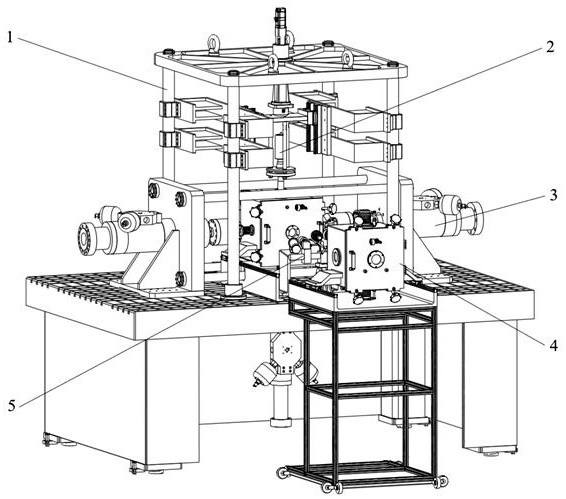

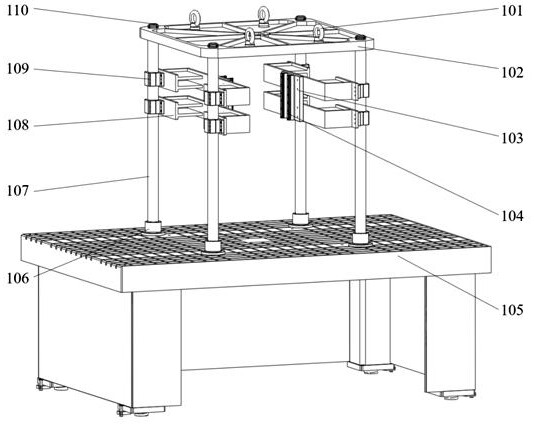

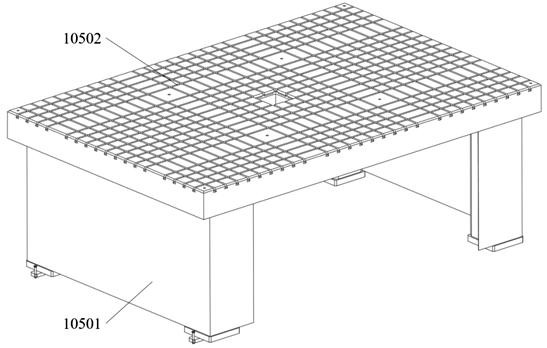

[0056] see Figure 1 to Figure 24 As shown, the in-situ test instrument and method for the mechanical properties of materials under high-temperature complex mechanical loads of the present invention is composed of supporting frames, high-frequency fatigue loading, static and dynamic mechanical load loading, high / low temperature loading, in-situ monitoring and other modules. Among them: the support frame module is used to realize stable support and effective vibration isolation for each functional module of the instrument; the high-frequency fatigue loading module is used to realize high-frequency fatigue loading on the tested sample, and static bending preload can also be applied according to actual test needs The static and dynamic mechanical load loading module is used to realize the combined loading of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com