Digital profiling control system and method based on programmable logic device

A technology of programming logic and control system, applied in the field of digital profiling control system, can solve the problems of different acceleration and deceleration time and response time, long mold production cycle, high cost, improve stability and reliability, and speed up data exchange , the effect of less address resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

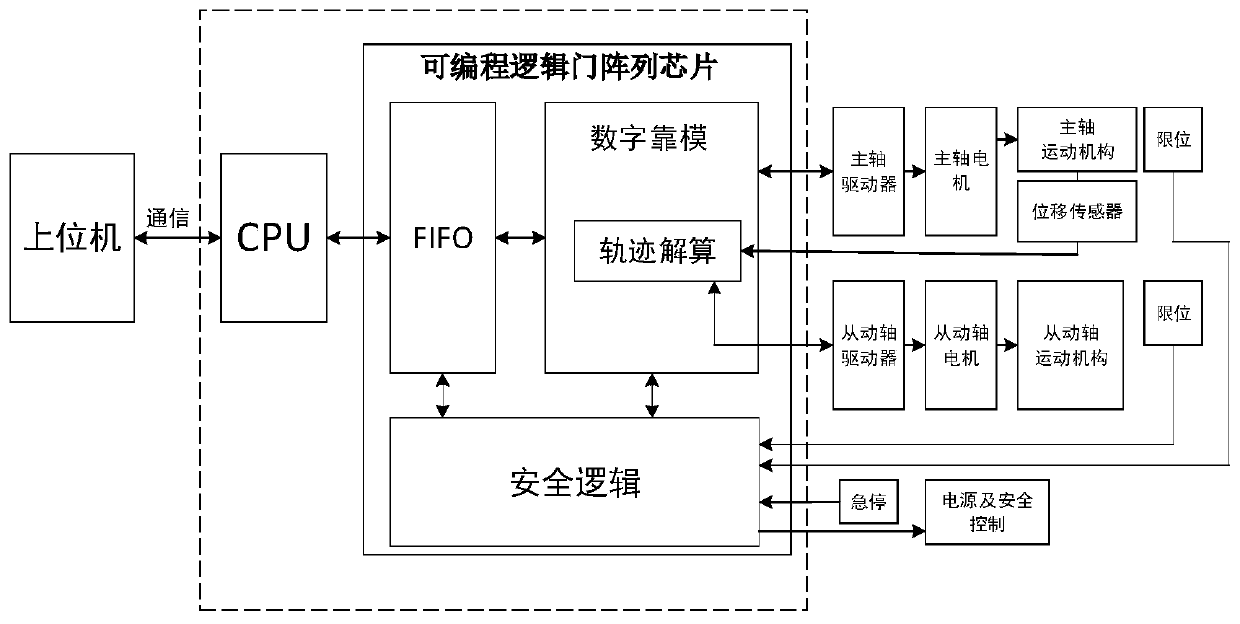

[0031] This embodiment proposes a digital profiling control system based on programmable logic devices, such as figure 1 As shown, the system includes a FIFO unit, a digital model unit and a safety logic unit based on programmable logic devices.

[0032] Wherein, both the digital profiling unit and the safety logic unit communicate with the external host (CPU) through the FIFO unit to realize the data exchange channel between the master and the slave, and have the advantages of fast data exchange speed, less occupied system address resources, and high reliability. advanced features. The safety logic unit communicates with the digital profiling unit; the digital profiling unit is used to complete the control output and state information reading of the main shaft and the driven shaft, and realize the linkage control of the main shaft and the driven shaft; the safety The logic unit is used to collect and process machine tool safety-related information to realize safety control. ...

Embodiment 2

[0040] Based on the control system of the above-mentioned embodiment 1, this embodiment also proposes a digital profiling control method based on programmable logic devices, which specifically includes:

[0041] The FIFO unit is built in the programmable logic device to realize the data exchange between the external host and the internal data of the programmable logic device, which has the characteristics of fast data exchange, less system address resource occupation and high reliability.

[0042] The programmable logic device completes the control output and state information reading of the main shaft and the slave shaft, and realizes the linkage control of the main shaft and the slave shaft. Specifically:

[0043] During automatic processing, the spindle movement is controlled by the programmable logic device, and the instantaneous displacement increment of the spindle feed is detected by the displacement sensor and transmitted to the programmable logic device, which is base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com