Correction method for pointing error of biaxial rotation system based on spherical crown function

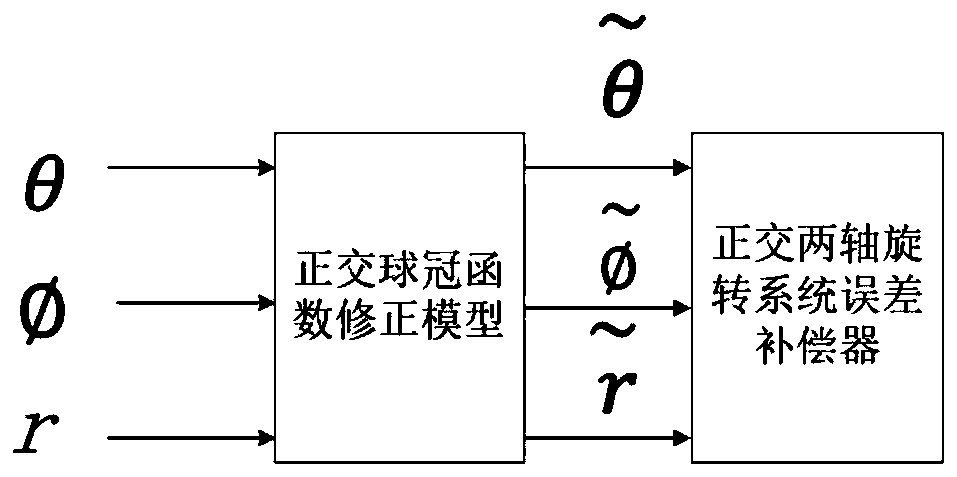

A dual-axis rotation and pointing error technology, applied in complex mathematical operations, control using feedback, electrical digital data processing, etc., can solve problems affecting the accuracy of correction, poor stability, large condition number of normal equations, etc., to achieve correction accuracy High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] The method of the present invention is applicable according to two situations:

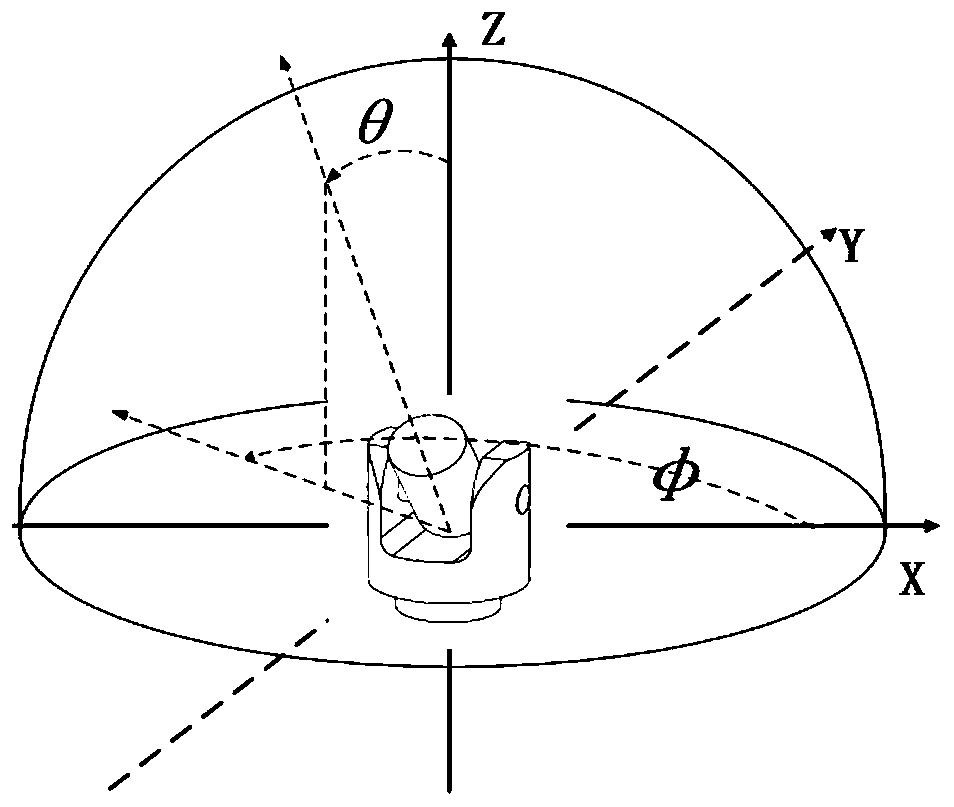

[0057] (1) If the area covered by the error model is smaller than the hemisphere, then HSH, ZSF and LSF can all be used;

[0058] (2) If the area covered by the error model exceeds the hemisphere, both ZSF and LSF can be used, and the maximum zenith angle θ can be determined according to the distribution of the error data 0 .

[0059] For convenience, the following discussion uses HSH as an example (the use of ZSF and LSF is the same as that of HSH).

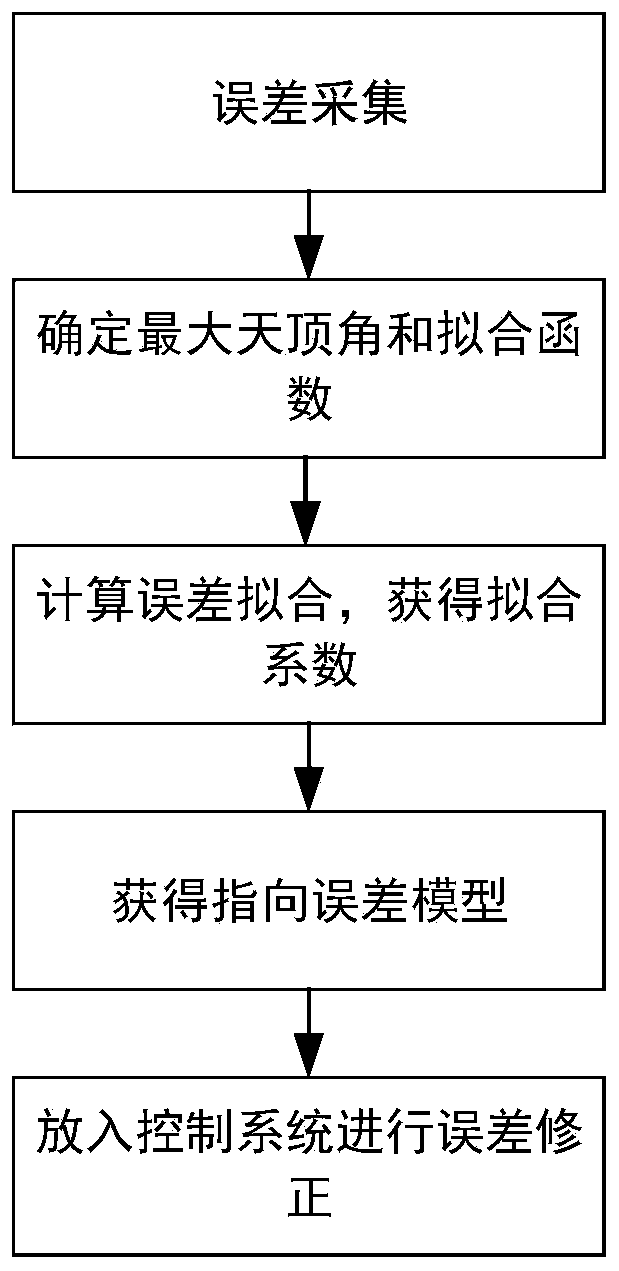

[0060] Method steps of the present invention are as figure 1 shown, including:

[0061] Step 1: Error collection

[0062] Step 1-1 select theoretical value

[0063]Divide the pointing spherical cap into s surface elements (preferably uniform division), measure on each small surface element, and obtain the theoretical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com