Solar cell, preparation method thereof and photovoltaic module

A technology of solar cells and photovoltaic modules, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of reducing photoelectric conversion efficiency of modules, increasing material costs, increasing module area, etc., and achieve the effect of reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

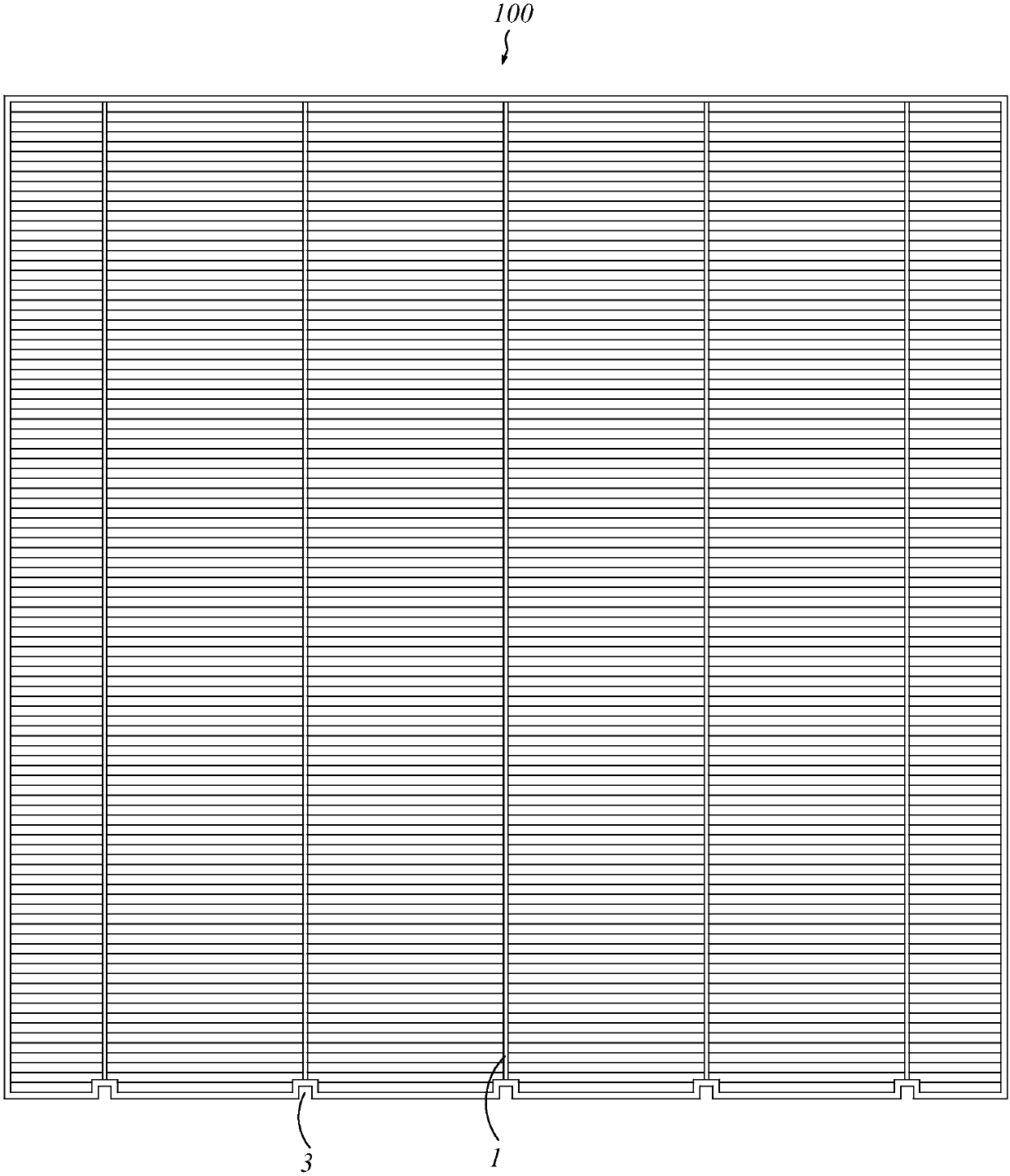

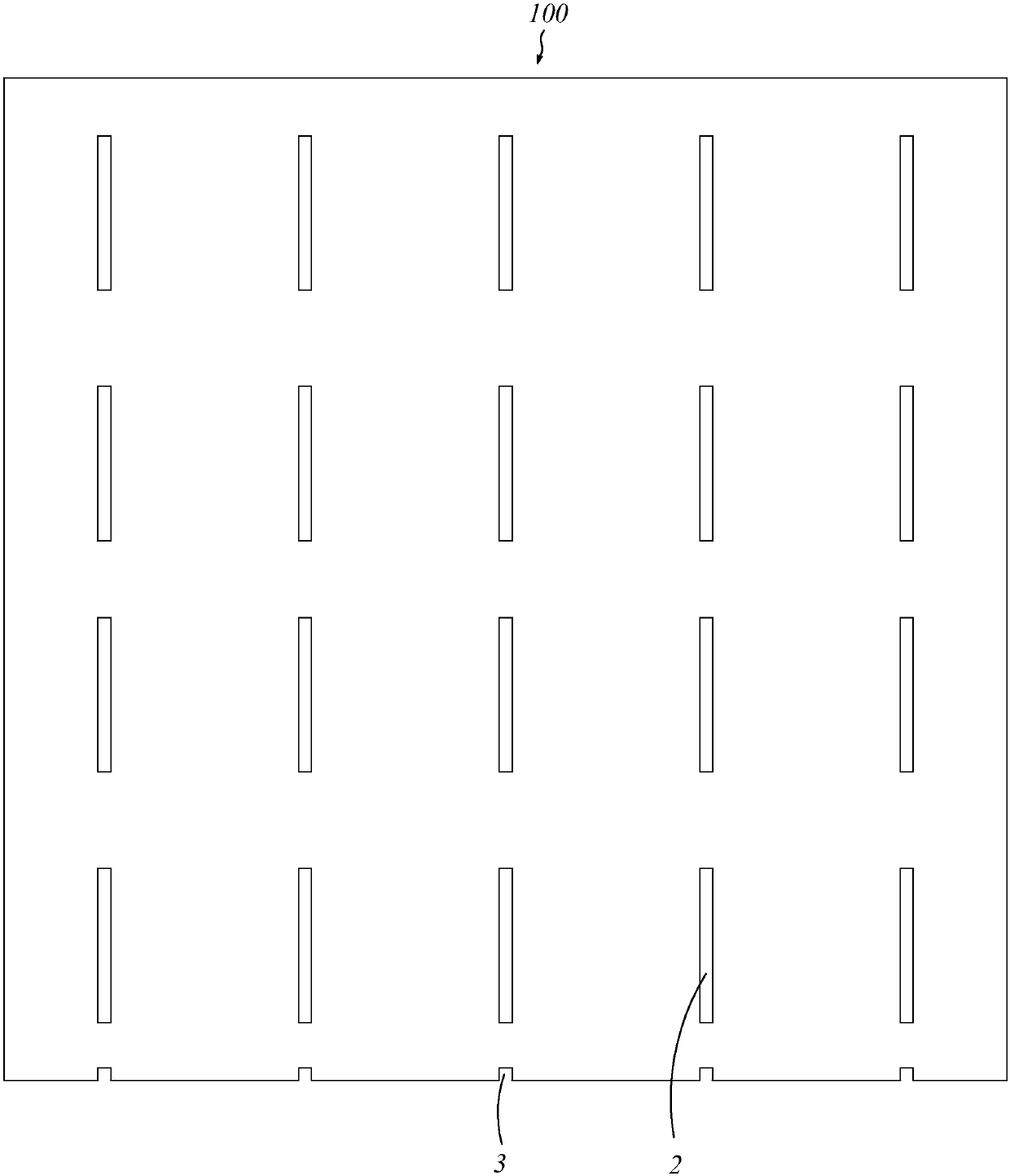

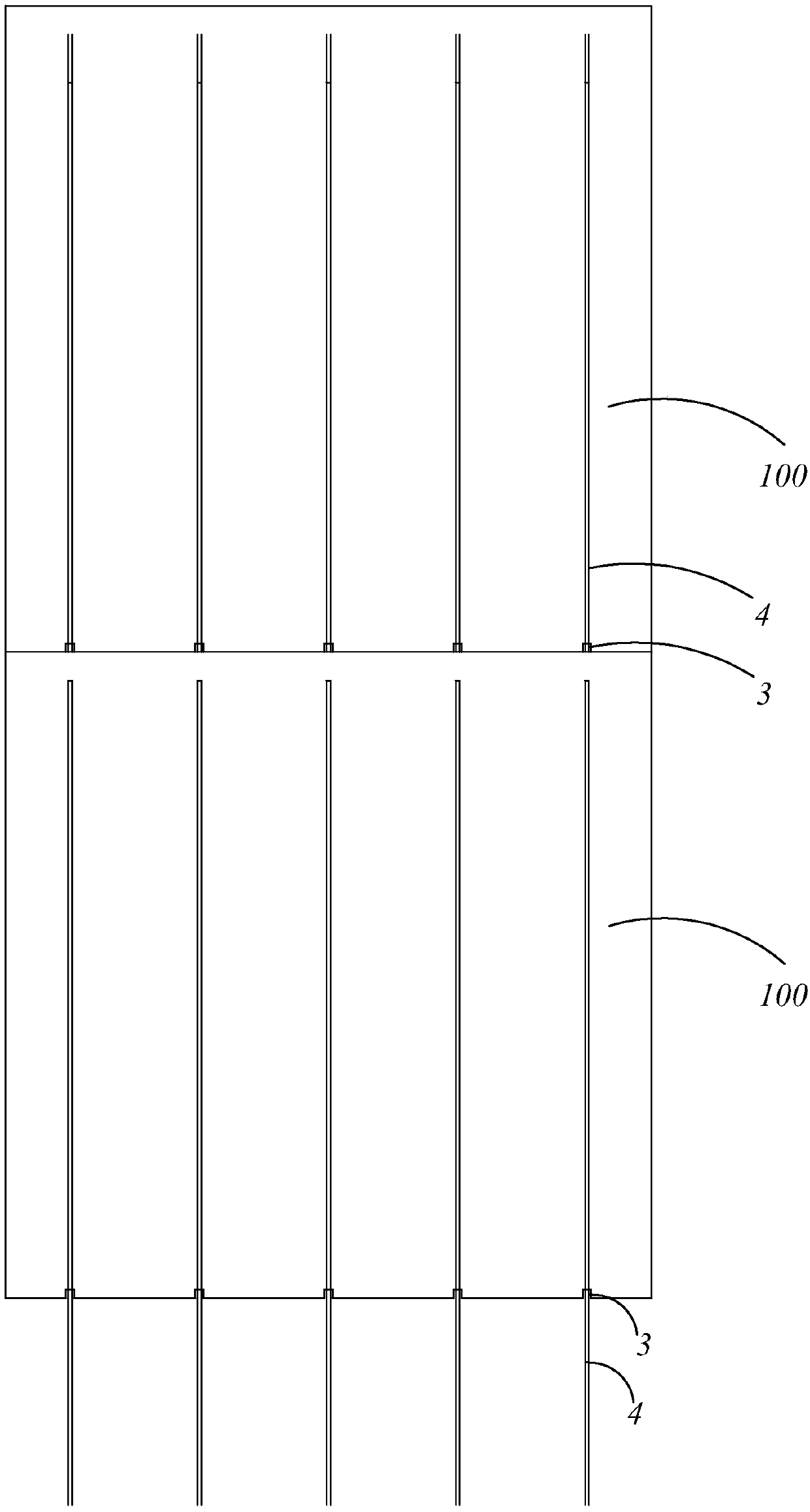

[0040] Such as Figure 1~Figure 10 Shown is a solar battery sheet 100 in a preferred embodiment of the present invention, the surface of the solar battery sheet 100 is provided with several main grids (1, 2), and the edge of the solar battery sheet 100 is provided with several The grid (1, 2) corresponds to the through groove 3. Those skilled in the art can understand that the “several busbars” mentioned above may be part or all of the busbars on the surface of the solar cell 100 .

[0041] By opening the through groove 3 on the edge of the solar battery sheet 100, the crack phenomenon of the solar battery sheet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com