Preparation method of modified glutinous rice flour

A technology of glutinous rice flour and pre-gelatinized glutinous rice flour, which is applied in food ingredients as taste improvers, food drying, food science, etc. It can solve the problems of easy cracking, poor water absorption and water retention of glutinous rice flour, and affecting the quality of quick-frozen glutinous rice balls, etc. , to achieve the effects of increasing water absorption, improving freeze-thaw stability, and improving the delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

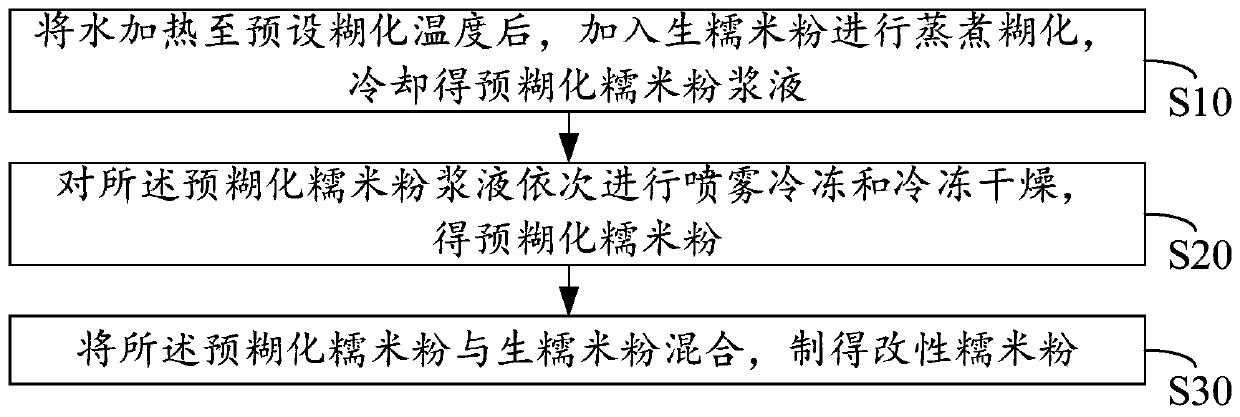

[0030] Glutinous rice flour usually needs to be gelatinized and dried during the preparation process. Since the gelatinized glutinous rice flour cannot form gluten like flour, it needs to add a lot of water when it is made into food, resulting in too much free water, while glutinous rice flour The water absorption and water retention are poor. During the freezing process, the food produced is prone to cracking and other problems due to the loss and migration of water during freezing, which affects the quality of quick-frozen glutinous rice balls. In view of this, the present invention proposes a preparation method of modified glutinous rice flour, which uses the gelatinized glutinous rice flour prepared after pregelatinization of the glutinous rice flour to be backfilled into the raw glutinous rice flour, thereby improving the water absorption performance of the glutinous rice flour, figure 1 Shown is an embodiment of the preparation method of the modified glutinous rice flour ...

Embodiment 1

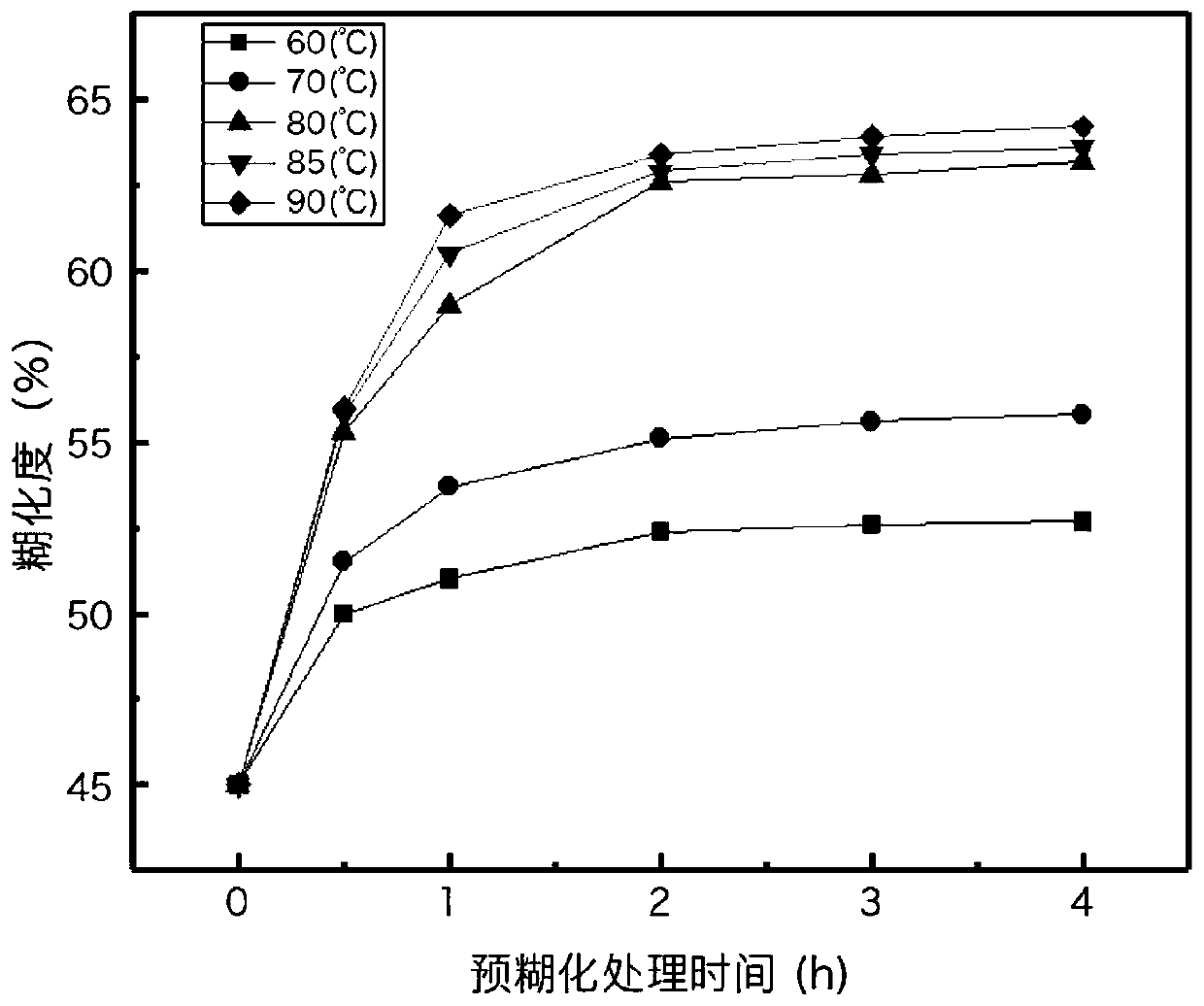

[0046] (1) Add water into the cooking pot and heat it to 80°C. After the temperature is stable, add raw glutinous rice flour into the cooking pot according to the solid-to-liquid mass ratio of 1:5, and then cook and gelatinize at this temperature for 2 hours, and the cooking is completed After leaving it to stand for cooling, the pre-gelatinized glutinous rice flour slurry is obtained;

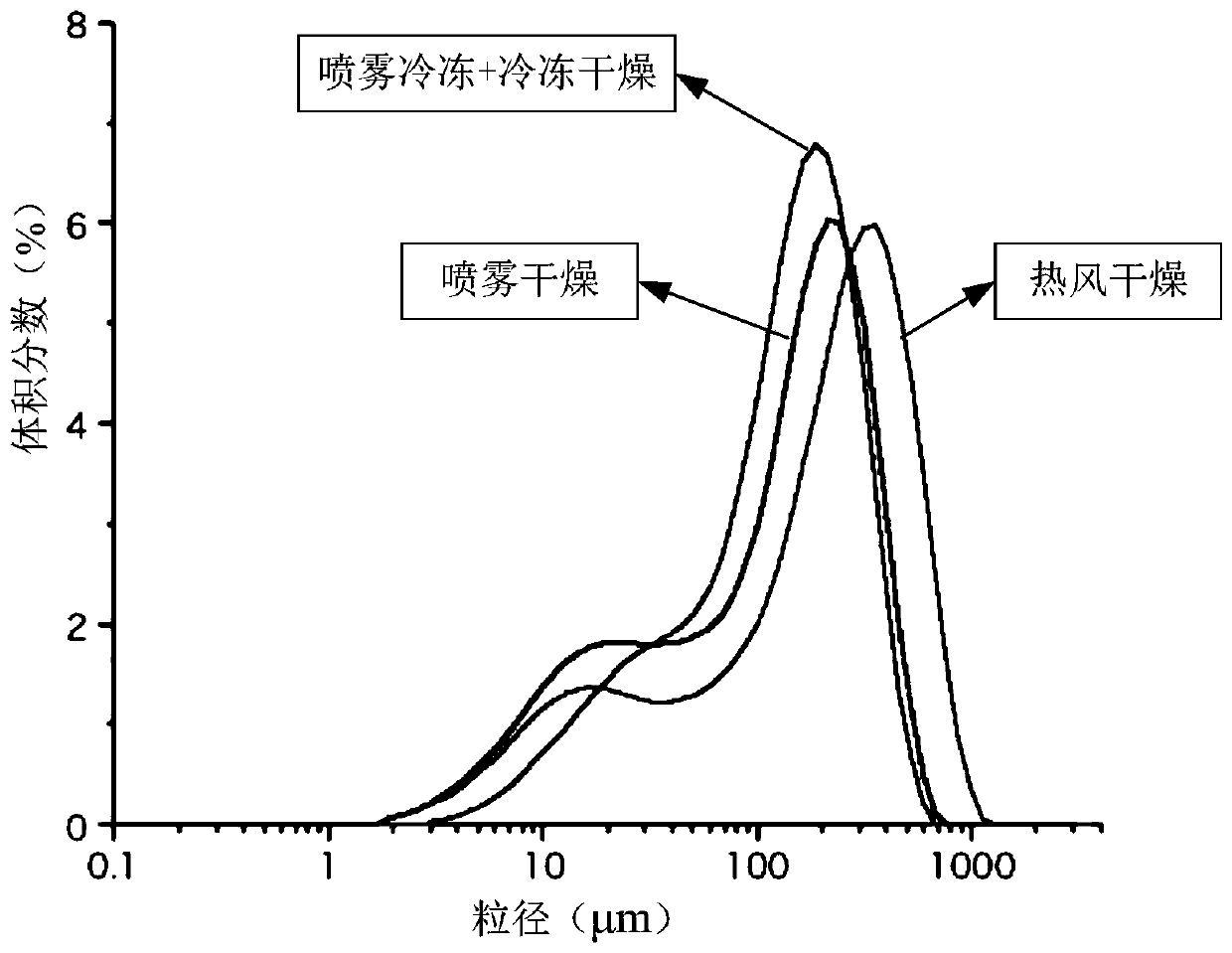

[0047] (2) Adopting the four-fluid nozzle of the air-flow type spray freeze-drying device, the pregelatinized glutinous rice flour slurry is atomized into micro-droplets, and the micro-droplets are contacted with liquid nitrogen by magnetic stirring to freeze and form frozen particles; wherein, Control the feed flow rate of the four-fluid nozzle to 30mL / min, the pressure of the compressed air to be introduced is 0.15MPa, and the air flow rate is 2m 3 / h, the distance between the nozzle and the liquid nitrogen is 15cm;

[0048] (3) Transfer the frozen granules into a freeze dryer, heat-dry at ...

Embodiment 2

[0051] (1) Add water into the cooking pot and heat it to 85°C. After the temperature is stable, add raw glutinous rice flour into the cooking pot according to the solid-to-liquid mass ratio of 1:4, and then cook and gelatinize at this temperature for 1 hour, and the cooking is completed After leaving it to stand for cooling, the pre-gelatinized glutinous rice flour slurry is obtained;

[0052] (2) Adopting the four-fluid nozzle of the air-flow type spray freeze-drying device, the pregelatinized glutinous rice flour slurry is atomized into micro-droplets, and the micro-droplets are contacted with liquid nitrogen by magnetic stirring to freeze and form frozen particles; wherein, The feed flow rate of the four-fluid nozzle is controlled to be 15mL / min, the pressure of the compressed air is 0.01MPa, and the air flow rate is 1m 3 / h, the distance between the nozzle and the liquid nitrogen is 14cm;

[0053] (3) Transfer the frozen granules to a freeze dryer, heat and dry at -40°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com