Production method of wholegrain meal replacement powder

A production method and technology of whole grains, applied in food science and other directions, can solve the problems of moisture and deterioration of meal replacement powder, difficult to control the amount of use, inconvenient eating, etc., to improve the taste, improve the convenience and efficiency of eating, and facilitate quantitative consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

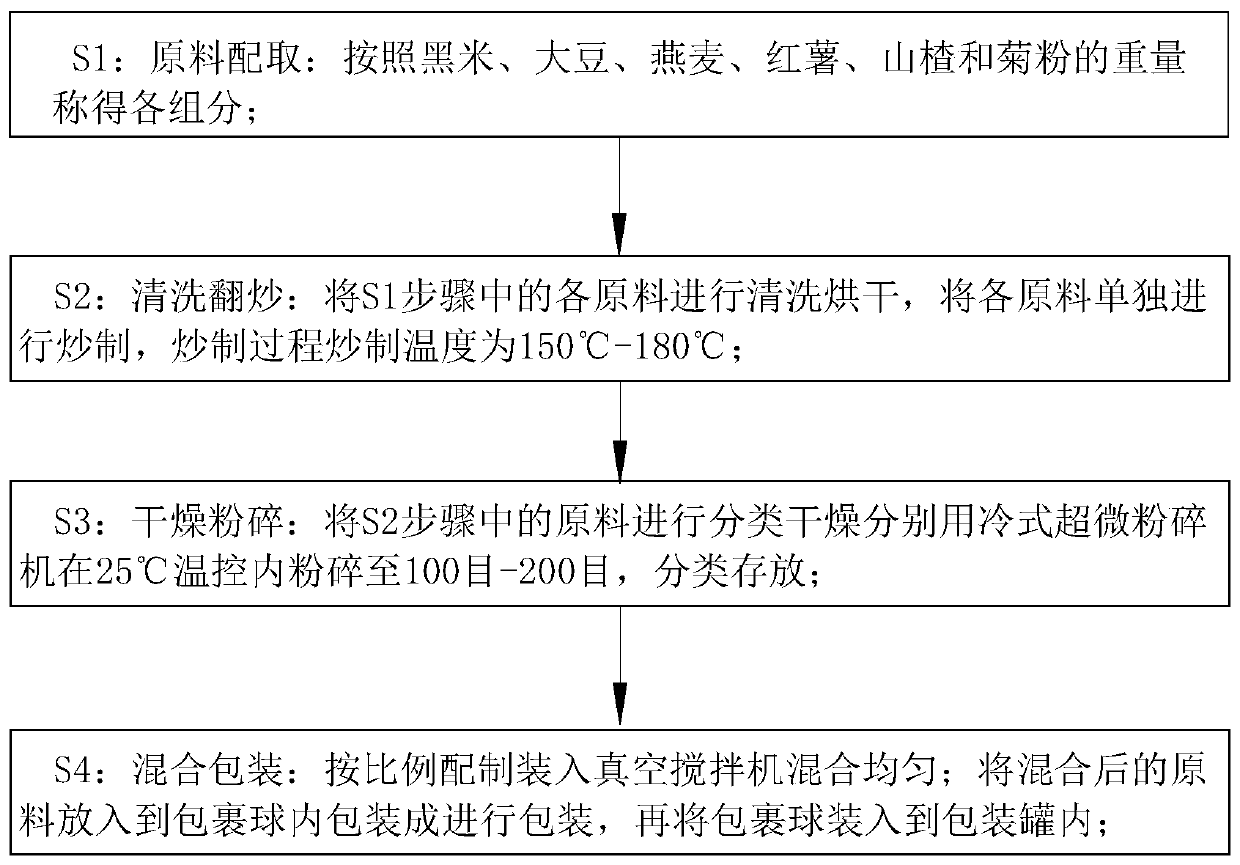

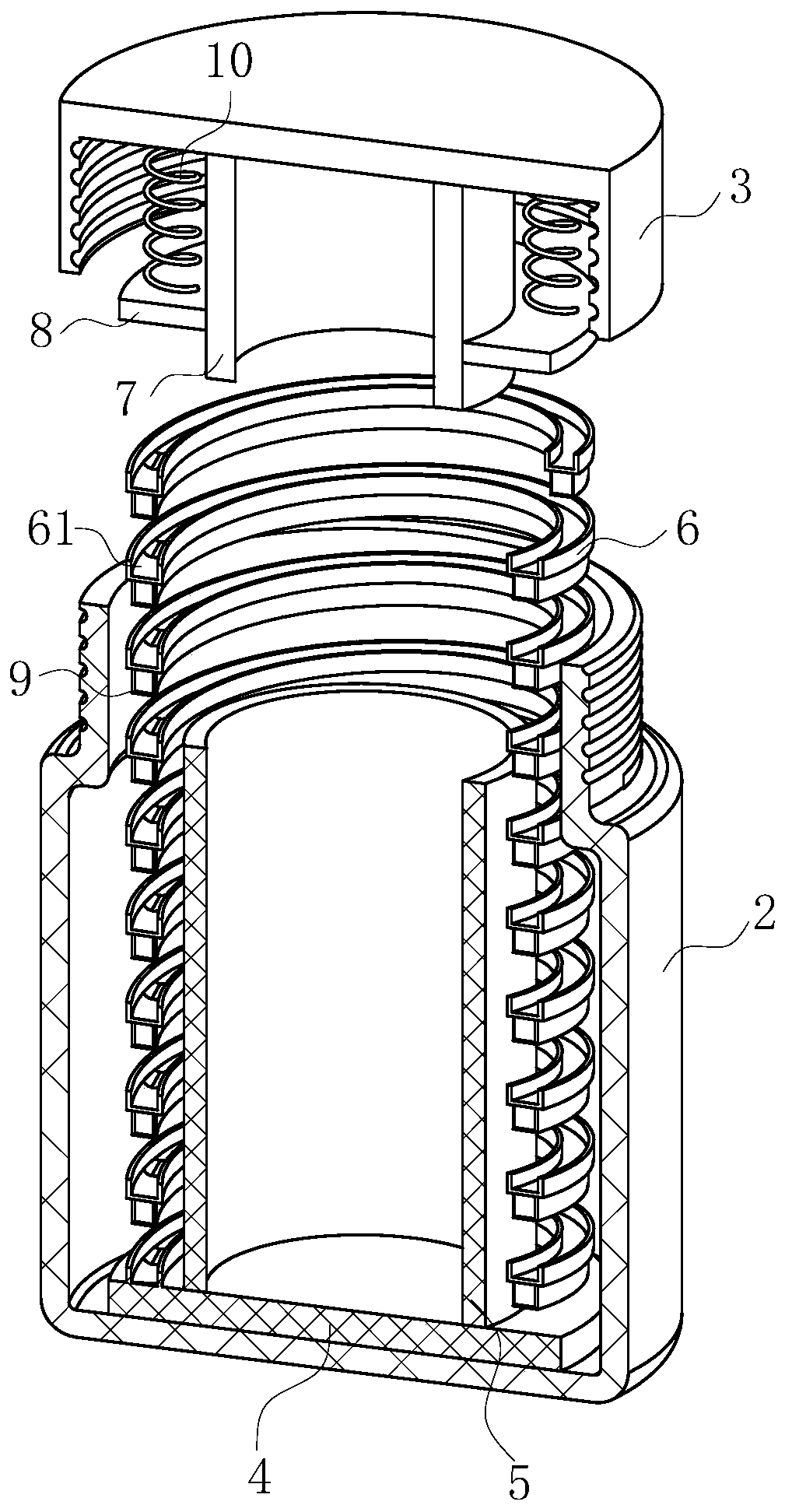

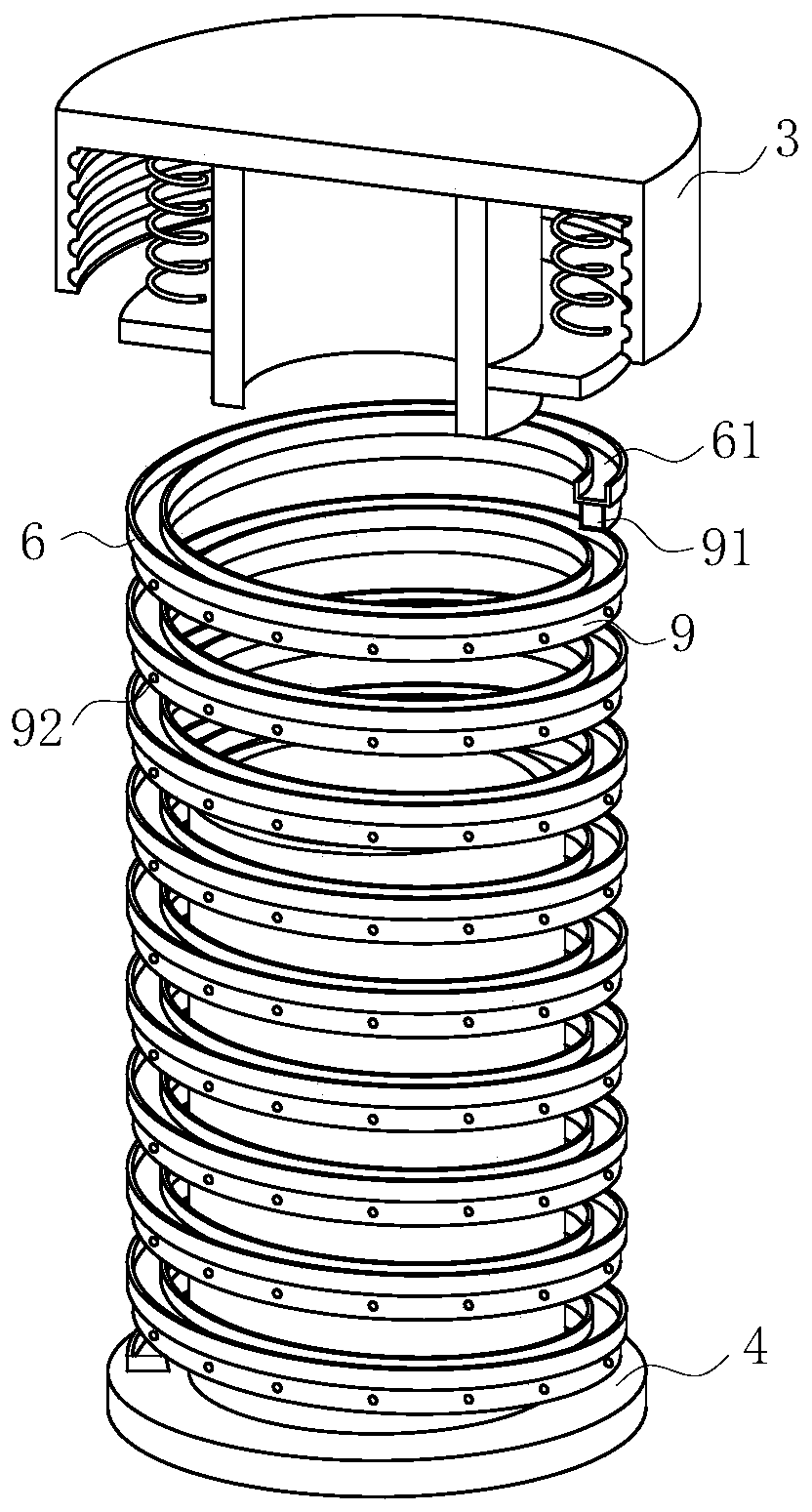

[0026] use Figure 1-Figure 4 The preparation method of a whole grain meal replacement powder according to an embodiment of the present invention is described as follows.

[0027] Such as Figure 1-Figure 4 As shown, a kind of preparation method of whole grains meal replacement powder of the present invention, the method comprises the following steps:

[0028] S1: Raw material preparation: Weigh each component according to the weight of black rice, soybean, oat, sweet potato, hawthorn and inulin;

[0029] S2: Cleaning and stir-frying: washing and drying each raw material in step S1, and frying each raw material separately, and the frying temperature during the frying process is 150°C-180°C;

[0030] S3: Drying and pulverization: classify and dry the raw materials in step S2, respectively pulverize them to 100-200 mesh with a cold ultrafine pulverizer under temperature control at 25°C, and classify and store them;

[0031] S4: Mixed packaging: prepare according to the propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com