Gel preparation device for SDS-PAGE (sodium dodecylsulfate-polyacrylamide gel electrophoresis)

A preparation device and gel technology, which is applied in the field of gel preparation devices, can solve problems such as time-consuming, rework, and unavoidable solidification time, and achieve the effects of saving waiting time and preventing glue leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

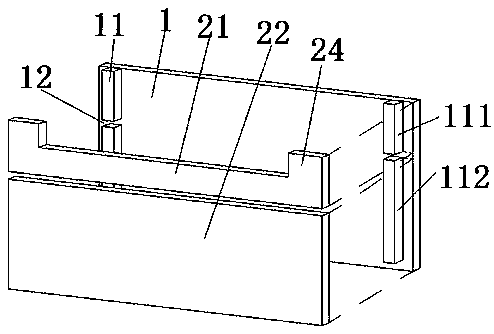

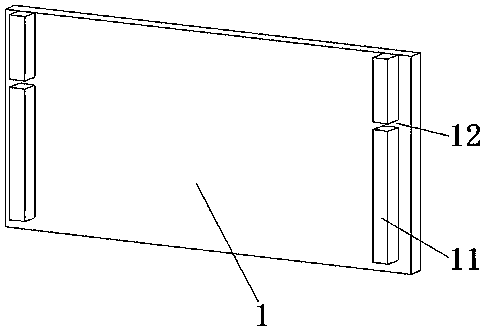

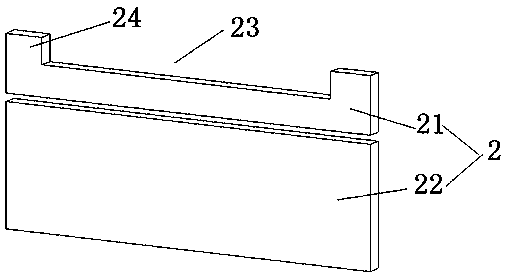

[0051] Such as figure 1 , 2 , 3, a gel preparation device for SDS-PAGE, comprising a back plate 1 and a front plate 2, spacers 11 are respectively set on both sides of the back plate 1, gaps 12 are set on the spacers 11, and the The front board 2 is made up of a front upper board 21 and a front lower board 22 .

[0052] Further, two spacers 11 are arranged in parallel.

[0053] Further, the gap 12 divides the spacer 11 into an upper spacer 111 and a lower spacer 112 .

[0054] Further, after the rear panel 1 and the front panel 2 are assembled, the notch 12 corresponds to the gap between the front upper panel 21 and the front lower panel 22 .

[0055] Further, a notch 23 is provided on the upper edge of the front upper plate 21 , and plate ears 24 are formed on both sides.

Embodiment 2

[0057] On the basis of Example 1, as Figure 4 As shown, a sealing strip 3 is also included, and the sealing strip 3 is connected as a whole by a bottom sealing strip 31 , a side sealing strip 32 and a middle sealing strip 33 .

[0058] Further, the sealing strip 3 is used to seal the gap between the rear panel 1 and the front panel 2, so as to ensure that the glue will not leak out during the glue making process.

[0059] Further, the bottom sealing strip 31 is used to seal the gap between the bottom of the front lower panel 22 and the rear panel 1 , and the side sealing strip 32 is used to seal the rear panel 1 and the front panel 2 The gap between the two sides, the middle sealing strip 33 is used to block the gap between the bottom of the front upper board 21 and the rear board 1 .

Embodiment 3

[0061] On the basis of Example 2, such as Figure 5 As shown, the section of the middle seal 33 is "L" or "⊥" type, and the positional relationship in the gel device is as attached Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com