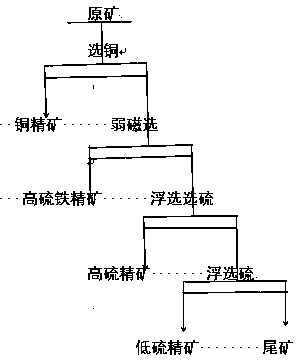

Method for recovering sulfur and iron from complex copper sulfur and iron polymetallic ore containing easily floatable silicate gangue

A polymetallic ore recovery method technology, applied in chemical instruments and methods, flotation, magnetic separation, etc., to achieve the effect of improving operating conditions, eliminating interference, and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

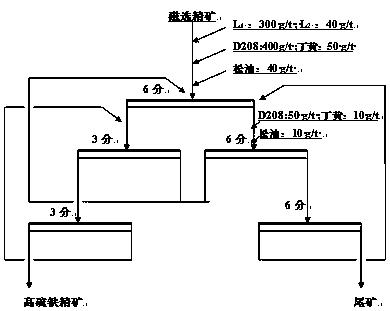

Examples

Embodiment Construction

[0012] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments without creative efforts by those skilled in the art fall within the protection scope of the present invention.

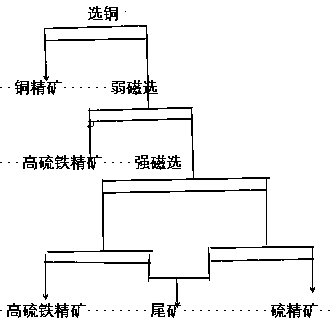

[0013] Such as figure 2 As shown, the present invention is aimed at the improvement of the complex copper-sulfur-iron polymetallic ore sulfur-iron recovery process of the existing easy-to-float silicate gangue. The high-strength high-strength magnetic separator performs magnetic separation on the tailings of weak magnetic separation and then performs flotation, which has achieved unexpectedly good results, low cost of improvement, and large benefits.

[0014] Such as figure 2 As shown, the weak magnetic separat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap